FORT WORTH, Texas — Railroading’s path is clearly heading away from the diesel-electric locomotive, the builders of those locomotives agree.

Where that path leads is far less clear, representatives of Alstom, Progress Rail, Siemens, and Wabtec said in a discussion at last week’s Railway Supply Institute Conference. Battery power, hydrogen, and hybrids of all sorts all have a chance to play a role, but what those roles will be, it’s too soon to know.

Michael Cleary of Alstom sales and business development compares the way forward to the “spaghetti diagram” of a hurricane forecast: “There’s all these divergent paths of where everything is going to end up, but with more time and data, it starts to converge.

“I think we’re going to get to the common theme of what it’s going to look like in this industry, but it’s just going to take us a while.”

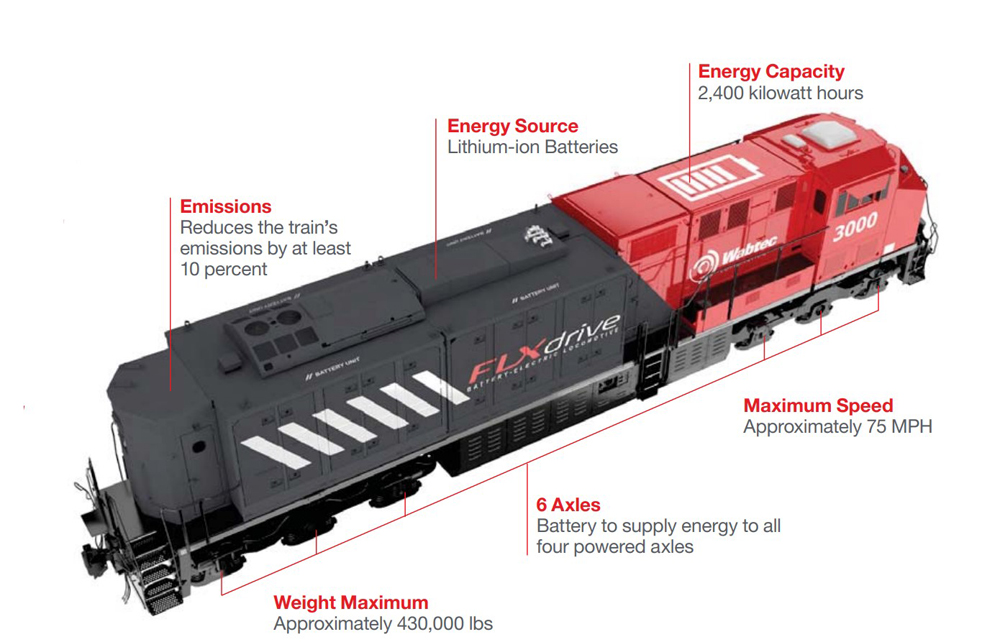

Venu Madala, Wabtec group vice president, product management, discussed the FLXdrive battery-electric tests conducted in 2021 with BNSF see and said they should that a unit with greater energy storage capability than the demonstrator’s 2.4 Megawatt-hours could have achieved 25% to 30% fuel savings. [See “Wabtec says next generation of battery-electric …,” Trains News Wire, May 17, 2021]. Wabtec is now working on an 8 MwH road unit.

“So the operations demonstrate that the fuel savings are there, which make economic sense along with getting the sustainable solutions,” Madala said. “Because without economics, it’s going to be a hard option for railroads, and that’s what we’re focused on, to make it palatable for the customers.”

In keeping with Cleary’s concept of different paths, Madala believes there will be no one sustainable motive-power solution for everyone.

“Everybody is going to have a very unique fleet, and they’re going to have very unique requirements from their fleet strategy perspective. And our goal is that we’re going to be able to help each customer uniquely by having solutions available in different areas.”

Hydrogen is also likely to be among that mix of solutions. Progress Rail, which also has battery locomotives on the way, is working with BNSF and fuel company Chevron on one of several hydrogen fuel-cell locomotive projects [see “BNSF to join Caterpillar, Chevron in hydrogen fuel-cell project,” News Wire, Dec. 14, 2021]. Michael Cleveland, Progress’ director of advanced energy, touched on how much there is to learn about an all-new technology.

“The promise of only water coming out your tail pipe is really impressive,” Cleveland says. “But being able to understand, how do you get fuel to it? What are the fueling times look like? What are the differences in the piping, and the behavior, and the response curves of fuel cells? That’s all new stuff for us …

“For some of us, this would be very daunting … On the other side of it, it’s a very exciting technical challenge. And looking at the faces I see around the room, I think more of us are excited about the technical challenge.”

Peter Tuschinski, vice president of rolling stock portfolio and product strategy for Siemens Mobility’s Rolling Stock Division, notes his company is already working on partial-zero-emission passenger solutions for the U.S. Amtrak equipment ordered in 2021 will use the company’s Charger diesel-electric in tandem with a pantograph-equipped coach that would allow the train to operate in electrified and non-electrified territory [see “Siemens optimistic about US passenger market,” News Wire, Sept. 24, 2022]. It is working on a similar solution with a battery-equipped coach that would allow short-range operations in areas such as tunnels leading into stations or urban city centers.

Battery technology is such, Tuschinski says, that zero-emission commuter operations are already possible; zero-emission intercity service will likely require hydrogen power. Even then, for a range more than about 150 miles, locomotives will likely require hydrogen tenders.

Sean Cronin, Metra’s senior director of mechanical capital projects, provided a customer’s perspective on the emerging technologies. Metra is involved in a project with Progress Rail to convert at least three of its diesels to battery power [see “Metra board approves deal …,” News Wire, Aug. 18, 2022] and is looking to purchase an electric switch engine.

“We need to get real-world data about what these new technologies do in our environments,” Cronin says. Safety, reliability, and costs — both to operate and maintain — will determine Metra’s ability to embrace the new choices.

“It’s the initial cost of the rolling stock. It’s the cost of the infrastructure, fueling and in the shops we maintain and in the depots. … We have to have a vision of the future, what the costs are going to be of this new fuel or power source we’re going to use. And then last, it’s the cost of the maintenance. We’ve all maintained diesel locomotives for a long time; we know how much it costs. But with some of these new technologies, how much does it cost, on both a 92-day and 184-day maintenance cycle, and on an overhaul cycle, for where I need to move capital to maintain these new pieces of rolling stock. …

“This is a new journey. I think we’re pretty open to the new technologies, but it’s got to work in the services that we provide, and the first thing we have to think of is that it has to work for our passengers.”

Two trains of thought: Battery locomotives vs hydrogen locomotives.

Battery; JUST TO MINE AND REFINE the Lithium for the batteries, that will last 7 or 8 years, causes more pollution than a Tier 3 Locomotive in it’s normal lifetime. OH by the way, that doesn’t include other metals. like nickel, that also make up the battery. You would also have to replace the batteries at least twice in the locomotives lifetime. Then comes the disposal of these toxic items.

People will ask why they would have to replace the batteries every 7-8 years. Co worker HAD an electric Toyota. They said it would last over 200,000 miles. Her’s had a little over 75,000 and died, Replacement battery and cost of disposing old battery was a lot more than the car’s bluebook value. Needless to say she got rid of it and bought a gasoline powered car.

Dan: a rational response. Too much time and money wasted on unproven technology. Simon: your response adds nothing.

Science’s knowledge base advances by baby steps over a long period of time. Technology lags behind the knowledge base. We have a desire but neither science base nor the technology to overcome obstacles as mentioned by Dan and Charles. It took 40 years to attain reliable railroad diesels, from Dr. Diesel’s invention to the FT. And Dr. Diesel’s diesel had to be greatly improved upon before wide spread application.

Lastly, for new technology to be applied all the components must also be in place to support that new technology. Again, all that development takes its own time to mature.

Lastly, all this must make NOT violate laws of economics no matter what political forces may tell us. Any business not making a profit goes out of business.

DAN, a post which shows understanding. The GREEN revolution aint got the answers and the issues here have nothing to do with anything to affect their questionable global warming predictions

I can sum the problem up quickly and save a lot of trees in the process. Scrap Tier 4. The EPA went too far in trying to gain only a slight improvement in emissions; the result has been to turn reliable, relatively cheap, fuel-efficient diesel locomotives into over-complicated, expensive, and unreliable maintenance headaches. The proposed alternatives are no better: lithium batteries are operationally unsafe and very destructive to the environment because of all the heavy mining, transportation, and manufacturing operations required to produce them. Disposing of used batteries will cause huge problems as well.

Electrifying everything is out of the question for the reasons listed above, and stringing catenary is only cost-effective on high-density lines.

Fuel cells might eventually prove to be useful. The technology was proven to be successful during the Apollo and Gemini manned spaceflight programs in the 1960s and ’70s, but they were only required to survive the stresses of launch and then work for 14 days in space. That’s a far cry from dealing with the extreme nature of the railroad operating environment day in and day out for 20+ years.

Bring back Tier 3, and let Wabtec, Progress Rail, and the other builders get back to doing what they have done successfully for decades. And then start building lots of nuclear power plants.

Whatever man, keep smoking those diesel fumes.

Railroads will be electrified or the tracks will be pulled up. Ultimately, that’s the only choice that they will all face, based on regulation.

If it’s too expensive, then they’ll be nationalized (and electrified).

Yeah a major step backwards. Socialism vs letting the free market decide what is most economical. Its not catenary on over branch line and spur. The extremist agenda will crush the economy.

i just don’t get it if transitioning from diesel locomotives too battery locomotives and hydrogen locomotives is going to solve the problem for zero emissions how come low emission diesel locomotives aren’t good for the environment i thought they have solved some emissions surely they could have find a way to run diesel locomotives to work together with battery locomotives and hydrogen locomotives

The path forward may be away from the diesel-electric locomotive, but the builders should keep building them. Who knows how long it will take until the technology is developed enough to produce a cost-effective, reliable replacement.

Proof reading? “…conducted in 2021 with BNSF see and said they should that a unit with greater energy storage capability…” or …conducted in 2021 with BNSF and said they should see that a unit with greater energy storage capability …

” Zero emissions”. No sir. While the locomotive may not emit them the power source that produces the electricity will.

Not necessarily. Safe Hatbor Dam on the Susquehanna River near Harrisburg can generate 25 Hz traction power directly.

What does Susquehanna River have to do with a rail system that covers 49 states?

It’s a start. Right now the NEC has the highest electric traction power usage in North America.

And a pantograph on the rear too?

Ever option but the blindingly obviously off-the-shelf one.

I’m not sure what I am seeing in that newer version of the Joule. Is that four axles on two bogies?

I wonder how long a lithium battery equipped locomotive would burn in a derailment? Greenwashing, probably getting substantial federal money.

My suggestion: string catenary now. Proven technology.

Stringing catenary will only further strain the electrical generation system that doesn’t have the capacity.

Catenary is proven technology but nothing resembling proven economics. Look at MBTA’s suburban rail where electrification has gotten exactly nowhere despite pressure from the politicos. MBTA doesn’t even run electrics where’s there has been catenary in place for over twenty years: Boston to Attleboro to Providence and beyond.

Some creative thought and engineering might change this objection. It is pretty clear that the central supply/distribution electrical methodology is outmoded. With the ability of modern computing to nearly instantaneously switch sources. the key will be to come up with a distributed sourcing/storage system. Lots of possibilities in a changing electrical infrastructure.

Need Special Issue on this Topic 🙂

I very much agree.

I see a lot of interest in this – from the industry, from politicians – and from skeptics.