GATINEAU, Quebec — A “near-urgent” track defect was detected but not repaired several days prior to the June 2021 derailment of a Canadian National train at a remote location on the railroad’s Chetwynd Subdivision in British Columbia, the Transportation Safety Board of Canada said in an investigation report released Monday.

Thirty-eight cars of a two-engine, 71-car train bound from Chetwynd to Prince George, B.C., derailed at 9:15 a.m. on June 3, 2021. The derailed cars included one of hydrogen peroxide and one with residue of sodium hydroxide. There were no injuries and no release of hazardous material.

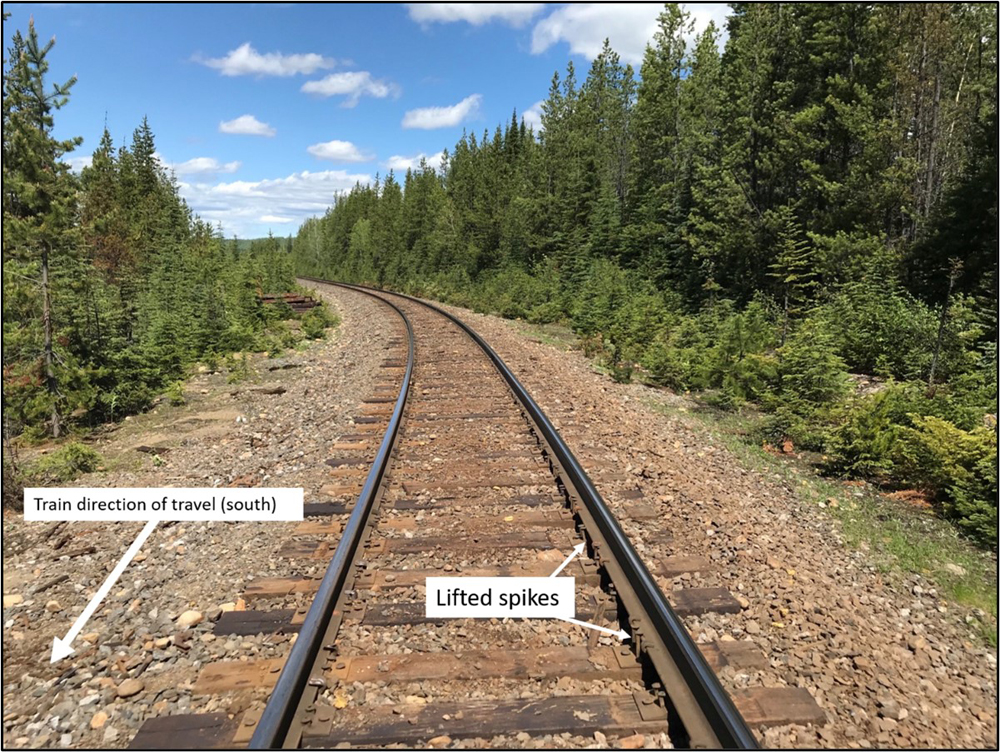

The derailment occurred some 85 miles north of Prince George, as the train negotiated an 8-degree curve into a bridge across the Parsnip River. Spikes on the high rail of the curve were found to have lifted out of the tie plates, allowing the gauge to increase and causing the cars to derail.

More than a week before the derailment, on May 25, a track geometry test car had recorded 30 feet of near-urgent outward rail cant on the low rail of the curve, which the report says is a sign of damaged ties, over-or under-elevated curves, spike issues (raised, missing, or broken), or excessive tie-plate cutting. No defects were recorded on an inspection the next day, the report notes, but adds “it is likely that signs of gauge widening (such as sliding tie plates, bent spikes, or plate cutting) were present, but not observed.” No repairs were made or other restrictions were put in place.

The safety message concluding the board’s report notes that during track inspections in curves, “it is important to pay particular attention to both rails for signs of instability, so that repairs or operating restrictions can be put in place.”

I would guess the loose spikes caused the outer rail to cant further outward, pushing the gauge wide and allowing the wheels on the inside of the curve to drop in.

Also makes one wonder if either locally or throughout the railroad there was more of an attitude towards keeping trains rolling than safety, though that is hard to imagine in such a major railroad.

Question: Was this inspection done with an AI Boxcar (or two) or was it done with humans in an inspection car. After all when the first inspection took place, found the problems then the next one not finding anything this should have been a red flag to the engineering department personal reading the results with comparison. Then what is “NEAR ERGENT’!!!!

Extra cant probably caused the train to stringline?

Thomas, I reread the article and THINK “If a second geometry car inspection…..”, is an error on your part. There was a second inspection, clearly stated.

I would think the “second inspection” was visual and thus not as precise as the “geometry inspection”. Even if a visual was done, it seems poorly done.

Regardless, THE FIRST inspection should have set off alarm bells that were not paid attention to. endmrw0222221031

You are correct. My mistake.

If a second geometry car inspection returned no defects, as reported here, the first inspection was likely dismissed as anomalous. The fact that a derailment occurred proves that the first inspection should have been followed by an on-site inspection. A visual inspection would certainly have resulted in remedial action.

Steven….that was my exact thought also….it sounds as though the geometry car operator did his job by reporting it, so where does the buck fall?

I would say it all begins with the track inspector which on NS, where I worked, would be the assistant track supervisor, who should have put slow orders on the defects. The defects would be recorded on the daily inspection report and what remedial actions, if any, were taken. The track supervisor should have been notified and it would be up to him to have the defects repaired and/or slow ordered. Sounds to me like this would be local engineering management’s fault.

If that’s the way the track looked when the geometry car passed over it, then it should have immediately been taken out of service until repaired. There are usually one or two engineering dept. officers aboard while testing, and I find it hard to believe that they didn’t do so.