Unlike modern machines, the steam locomotive — which underwent few fundamental changes in 125 years of development — openly displays many of its parts. This mechanical honesty has long captivated onlookers and invited study, but many still wonder just how steam locomotives work. In fact, entire books have been devoted to the subject.

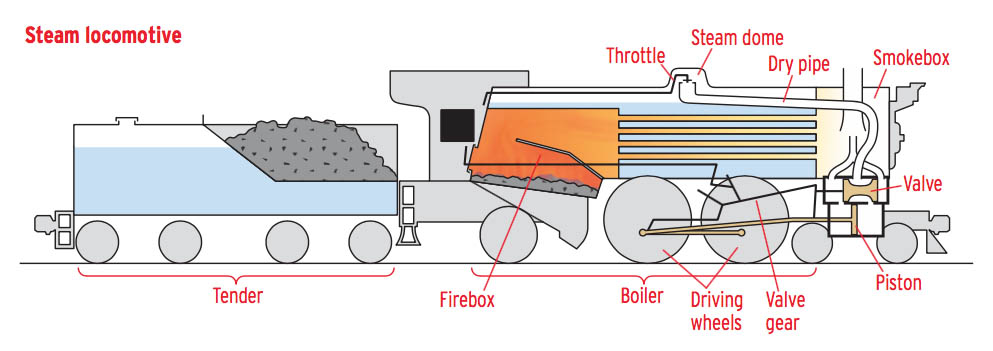

There are two basic areas of activity on a steam locomotive: the boiler where steam is made, and the engine (cylinders, rods, and driving wheels) where steam is used.

The essential action of any steam engine, stationary or mobile, is that of steam under pressure (200-300 PSI for most locomotives) entering a cylinder-piston assembly and pushing against the piston as it expands in an effort to reach normal atmospheric pressure.

Making steam

The production of steam begins with the fire, which rests on grates at the bottom of the firebox. Hot gases rise from the firebed to the upper portion of the firebox, or combustion chamber. On a coal-burning locomotive, the build-up of ash is controlled by shaking the grates so the ashes fall to the ashpan below. At the end of the run, the ashes are dumped from the ashpan hopper.

The gases move from the firebox forward through an array of pipes called flues, or tubes, in the main part of the boiler, which is filled with water. The best way to envision how the inside of a cylindrical boiler looks is to imagine a bundle of drinking straws in a glass (only the glass would be resting on its side, not upright).

Heat from the gases in the flues brings the water to a boil, making steam. The steam rises to the top of the boiler and is collected in the dome, where the throttle regulating the flow of steam to the cylinders is typically located. (More modern locomotives had their throttles located in the smokebox.)

The dry pipe carries the steam from the dome forward to the superheater, an improvement that came into wide use around 1910. The superheater is simply an arrangement of tubing that conducts the steam back through extra-large flues, where it is heated to a higher temperature, before returning it to the steam delivery pipes leading toward the cylinders. The use of superheated, as opposed to saturated, steam brought a 25-30 percent increase in the efficiency of the steam locomotive.

As a pressure vessel, the boiler must be carefully managed, lest it blow up. Safety valves are designed to automatically let steam escape if the boiler pressure gets too high. The top of the firebox, called the crown sheet, must be covered with water at all times. If the water level falls below the crown sheet, the fire’s heat can weaken it, causing the pressurized boiler to explode. Devices like the water gauge, or glass, are provided in the cab for the crew to monitor the water level. Low-water alarms are found on newer locomotives.

Using steam

From the steam delivery pipes, the steam enters the valve chests (one on each side). The valves, by moving back and forth, allow the steam to enter the cylinders at times when it can usefully push the pistons. When the steam has done its work, the valve has moved to let it escape, at considerably diminished pressure, to the blast pipe in the smokebox.

The motion of the valves is derived from the crosshead, which moves according to the rotation of the driving wheels and also is connected to the valve gear. The engineer works the valve gear with the reverse lever, so named because it is used to control the locomotive’s direction of travel as well as the timing of valve events.

Once the steam has pushed the piston, a series of linkages – piston rod to main rod, main rod to side rod, side rod to driving wheels – converts the piston’s back-and-forth motion to the rotational motion of the wheels. Counterweights placed opposite the point of attachment of the rods keep the driving wheels balanced.

The earliest locomotives had one pair of drivers, while the largest number of wheels driven from a single set of cylinders was six pairs. Because of their great size or the need for flexibility, many locomotives had two engines – two sets of driving wheels, each powered by a set of cylinders.

To help guide it into curves, many locomotives also had a small set of wheels (either one pair or two) in front beneath the smokebox called a lead or pony truck. Similarly, a two- or four-wheel trailing truck was placed at the rear of the locomotive to support the firebox.

There were many variations of wheel arrangements depending on a locomotive’s intended service and the era of its construction.

Exhausting smoke and steam

After the steam is used in the cylinders, it enters the smokebox via the blast pipe. As the exhaust steam blasts upward toward the stack, it provides a draft for the fire by drawing the gases through the flues and into the smokebox. (Fresh air enters the locomotive through open spaces at the base of the firebox.) The mingled exhaust steam and gases then leave the locomotive through the stack. It’s the relatively violent escape of steam from the cylinders that produce the familiar chuff-chuff sound.

As the exhaust is dependent on spent steam leaving the cylinders, provision must be made for exhausting the hot gases, or smoke, when the engineer has the throttle closed. A group of small steam jets called the blower is located in the smokebox for this purpose.

The smokebox also serves to collect partially burned particles of coal from the fire that have passed through the flues. When these accumulate to a depth sufficient to obstruct the flow of gases, some are picked up by the swirling exhaust and thrown out the stack as cinders.

Fuel, water, incidentals

Fuel (coal for most steam locomotives, oil for some, wood in the early days) and water are carried in the tender, a separate car semi-permanently coupled to the locomotive.

Coal was originally fed to the firebox by the fireman with a shovel, but locomotives of any size or modernity are fitted with mechanical stokers. Some locomotives intended for short-haul use were built without tenders; they carry a limited amount of their own supplies and are known as tank engines.

Water is added to the boiler by two injectors (one for the engineer, one for the fireman), or an injector and a feedwater heater. An injector uses steam to force water into the boiler, heating the water as it does so. Water from the injector is still cold compared to that in the boiler, so the check valve where it enters the boiler is placed forward, so as not to cool the water near the firebox. More efficient feedwater heaters, fitted to most big steamers after the mid-1930s, use exhaust steam to preheat the water.

Other accessories found on steam locomotives are safety features that have been carried over, albeit in altered form, as standard equipment on today’s diesel locomotives.

The headlight – and other electrical appliances such as marker lights and cab lights – is powered by a small steam-driven turbo-generator. Earlier headlights were oil-burning.

The pilot, which was gradually reduced in size from the “cowcatchers” of the mid-19th century, pushes aside obstructions. To accommodate brakemen, locomotives engaged in lots of switching often had footboards instead of pilots, but these have been outlawed on diesels for safety reasons.

Sand for traction is stored in one or more sand domes, or sand boxes as they’re sometimes called.

The whistle, mounted on the dome of many locomotives, could be placed in several different spots. Mechanical bell ringers replaced the simple action of a crewman pulling on a cord attached to the bell.

Fred, the sides are not even, they are out of phase with each other. If one side is balance, the other side is not, so the engine will always move.

Randy

I’ve asked this before and I never get an answer so I’ll try again. How are the throttle and the part I think is called an expansion tank in a walschaerts valve gear used to control the speed power at cetera of the locomotive? If you have the throttle wide open but the radius rod in the middle seems to me it ain’t going nowhere.

Same is true 3 years later. 🙂

Outstanding overview, easy to understand. Concise and well written.