WASHINGTON — The National Transportation Safety Board is calling for backup cameras on maintenance-of-way machinery, as well as other safety recommendations, as a result of a fatal accident involving a Norfolk Southern track gang at Reed, Pa., in December 2021.

The NTSB issued its final report on that accident on Thursday (Dec. 7). The probable case of the Dec. 8, 2021, incident, it said, was the inability of the operator of a spiking machine to see a contract worker behind his spiker as he backed up, and a malfunctioning horn and change-of-direction alarm on the machine.

Contributing to the accident, the report said, were a pre-shift inspection by NS that did not check the audibility of the horn and alarm; that equipment manufacturer Nordco Inc. allowed the machinery to leave the factory without making sure the change-of-direction alarm was working; and a 25-foot standoff distance set by the railroad, which was inadequate because of the visibility limitations of some maintenance equipment.

The NTSB is recommending that the Federal Railroad Administration require all new and rebuilt maintenance machines be equipped with backup camera, and that Class I and short line railroads equip new and existing machines with such cameras. It also called for the FRA to issue a safety alert on estabishing standoff distances — the amount of space maintained between workers and machines — that take into account operator visibility, and that Norfolk Southern revise its standoff-distance rule.

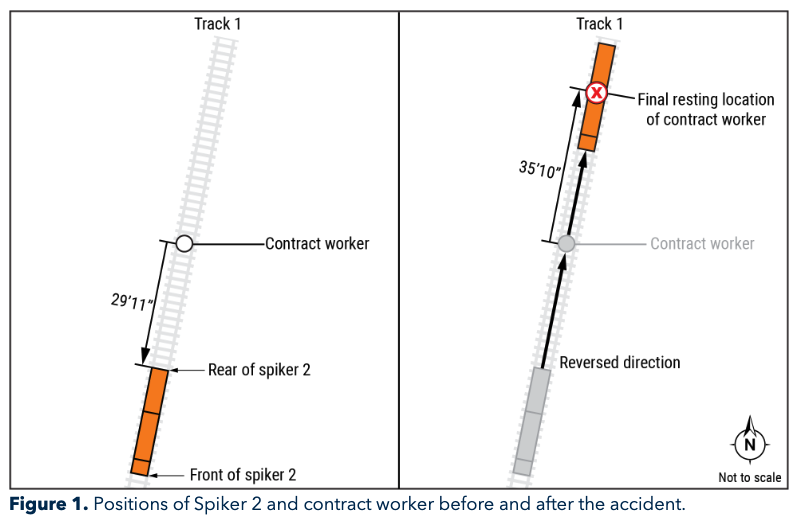

The incident occurred about 11:20 a.m., and killed a National Salvage and Service Corp. worker who was part of an NS track gang. Three spiking machines were working together when the middle machine in the group reversed after closing the gap with the lead machine. The operator of that machine said he blew his horn three times and looked in the mirror, then reversed direction, but struck the worker, who was standing behind him. Subsequent NTSB investigation found that just one of the four trumpets of the spiker’s horn was working, and the speaker for rear change-of-direction alarm was unplugged, so the alerts provided were barely louder than ambient noise and likely would not have been detectable for someone standing at least 25 feet away. The NTSB believes the change-of-direction speaker was unplugged because of improper connections that caused it to provide a back-up alert when the machine was moving forward.

When it was determined that the change of direction alert was faulted and not working correctly the machine should have been immediately taken out of service until it could be repaired or made functional. This is malfeasance at the least and the railroad and the manufacturer should be fined for not properly insuring a safety feature was working and the mans family properly taken care of.

The only work-around would have been to have had a side spotter who would signal with a bullhorn or other loud sounding device anytime a known defect would not protect a worker in the way. At least that way all workers around the machine would be notified by communications between the operator and the spotter that the unit would be changing direction until it could be fixed properly. I am amazed that this situation was allowed to continue (Alerter unplugged) and it cost a man his life. What the hell were these people thinking?

From the description of the horn and change of direction alarm the camera will just be one more item to not maintain.

Yes, for a railroad that has claimed recently that it takes safety seriously, this is fact that it doesn’t as this was an easily fixed problem but to them, keeping a machine operating in defect status was more important than a mans life and for this THERE IS NO EXCUSE ACCEPTABLE. Does an OSHA inspector have to be assigned to every maintenance of way (or other) operation to make sure every thing is done to protect life and limb? Maybe so when the job becomes more important than the problem. A pound of prevention for an ounce of cure!