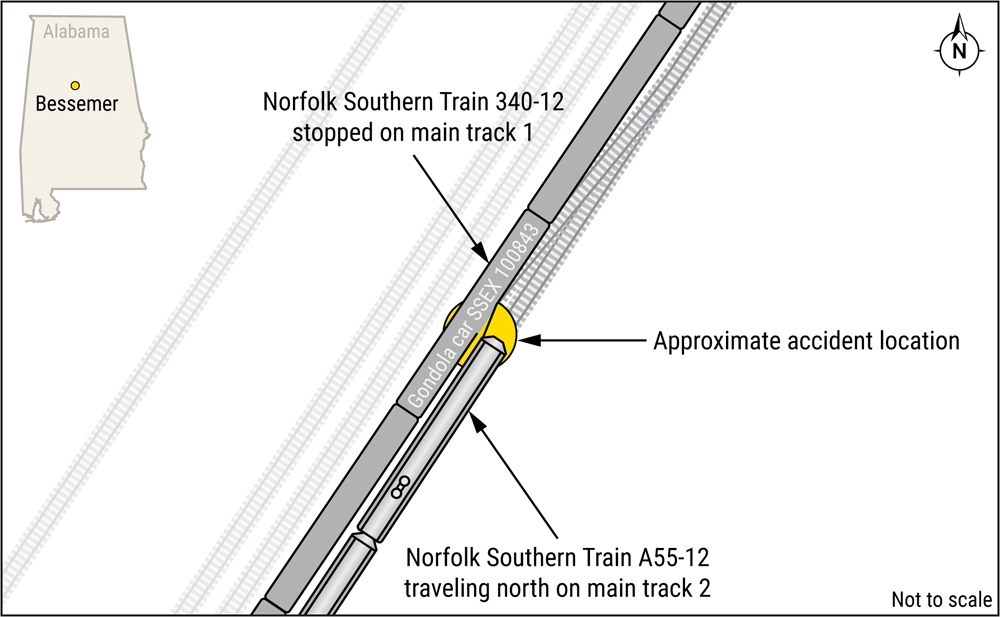

WASHINGTON — Nighttime visibility made it impossible for the train engineer to prevent or mitigate the accident in which a Norfolk Southern conductor trainee was struck and killed by protruding metal from a gondola car on an adjacent track in a incident in Bessemer, Ala., the National Transportation Safety Board said in the final report issued Tuesday on the Dec. 13, 2022, fatality.

The cause of death — a protruding length of steel angle iron from gondola SSEX 10084 that penetrated the cab window and struck the trainee — had been identified in the NTSB’s preliminary report [see “Preliminary report offers details …,” Trains News Wire, Jan. 18, 2023]. The trainee, not named in the report, was subsequently identified as Walter James Griffin III, of Hueytown, Ala. He died at the scene. The train’s conductor suffered minor injuries.

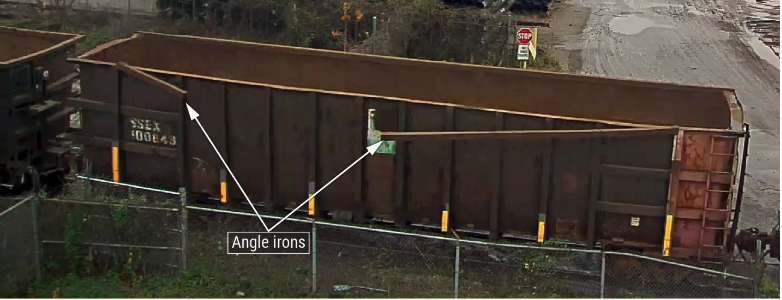

The car had been unloaded at a U.S. Pipe recycling facility and the section of angle iron — a piece of metal more than 16 feet long with 5-inch sides — had been welded to the car’s edge but had broken loose. The car was “taped off” while being handled by U.S. Pipe because of the damage, meaning it was not to be moved, but a 10-foot move to allow other work to continue broke that tape and the remaining tape was subsequently removed, leading to further handling of the car.

At the time of the incident, the damage was protruding on the car’s east side, fouling Main Track 2. The incident occurred just after midnight; the train was traveling at 54 mph when the engineer spotted the iron just before it struck the train and initiated an emergency brake application.

Surveillance camera images from U.S. Pipe show the protruding angle iron as the car left the facility on the morning of April 12; the conductor of the train involved in that movement told NTSB investigators that he was often looking down, to avoid scrap metal on the ground as he walked and to inspect brakes and wheelsets, suggesting he was not looking for defects at eye level or higher, the report notes. The conductor of a second train involved in moving the gondola only inspected the car from the opposite side because of unsafe walking conditions.

As a result of the incident, the Federal Railroad Administration issued safety bulletin to increase awareness of hazardous conditions and emphasize the importance of proper visual inspection of freight cars [see “FRA issues safety bulletin after fatal accident …,” News Wire, Jan. 6, 2023]. The Institute of Scrap Recycling Industries also highlighted the incident to its members and the Association of American Railroads issued a safety alert warning rail employees to watch for hazards extending from the top edge of gondola cars.

Every safety regulation of this type is written blood… The blood of those killed or injured in the first place.

In my training as a PC fireman back in 1969, it was EMPHASIZED that when meeting an opposing train get out of your seat and stand BEHIND the chair on the OPPOSITE SIDE of the cab to avoid getting injured by lading that could be protruding from the passing movement.

Is there any simple way to add a lock out system to the couplers making it impossible to connect cars that are otherwise marked for repairs?

They put a wheel locks on autos to keep them from being moved when ticketed. Why not oon train couplers. Since all couplers are essentially the same, you would think a clam-shell device could easily be manufactured, painted BRIGHT ORANGE and affixed over the coupler to indicate a car not to be moved, like valve covers used in power plants and other similar facilities to prohibit activation of a valve out of service. A lock out tag in blue (like other railroad tag out devices) could also be affixed by the individual attaching the device with enforceable penalties for removing someone else’s tag like in the rest of industry. Good idea Robert…

“Riding the shove” into scrap yards and making joints therein, especially in the dark, is one scary and dangerous aspect of switching. Another hazard is the overloading of the scrap material in the gons. Rule states cars are not to be accepted and switched out if the material is above the top edge of the car. Case by case decision by carriers and conductors. Very sad outcome for the crew in this case.