This new production system enables the plant to increase productivity and optimize the workforce, as well as reduce lead time and inventory. The assembly line cuts lead time by approximately 20 percent, reduces inventory by $1.75 million, and creates about 13,500 square feet of space savings within the factory.

For Afonso Borges, GE Transportation’s Industrial Director, lean processes can quickly accommodate different combinations and changes in demand, which is critical for sustainability.

“This new manufacturing approach allows for optimization of the whole production process and promotes the company’s lean culture,” explains Borges. “It enables us to improve the entire production system from end to end, and from the supplier to the final customer, which contributes to delivering better results, ensuring a more competitive and flexible business. “

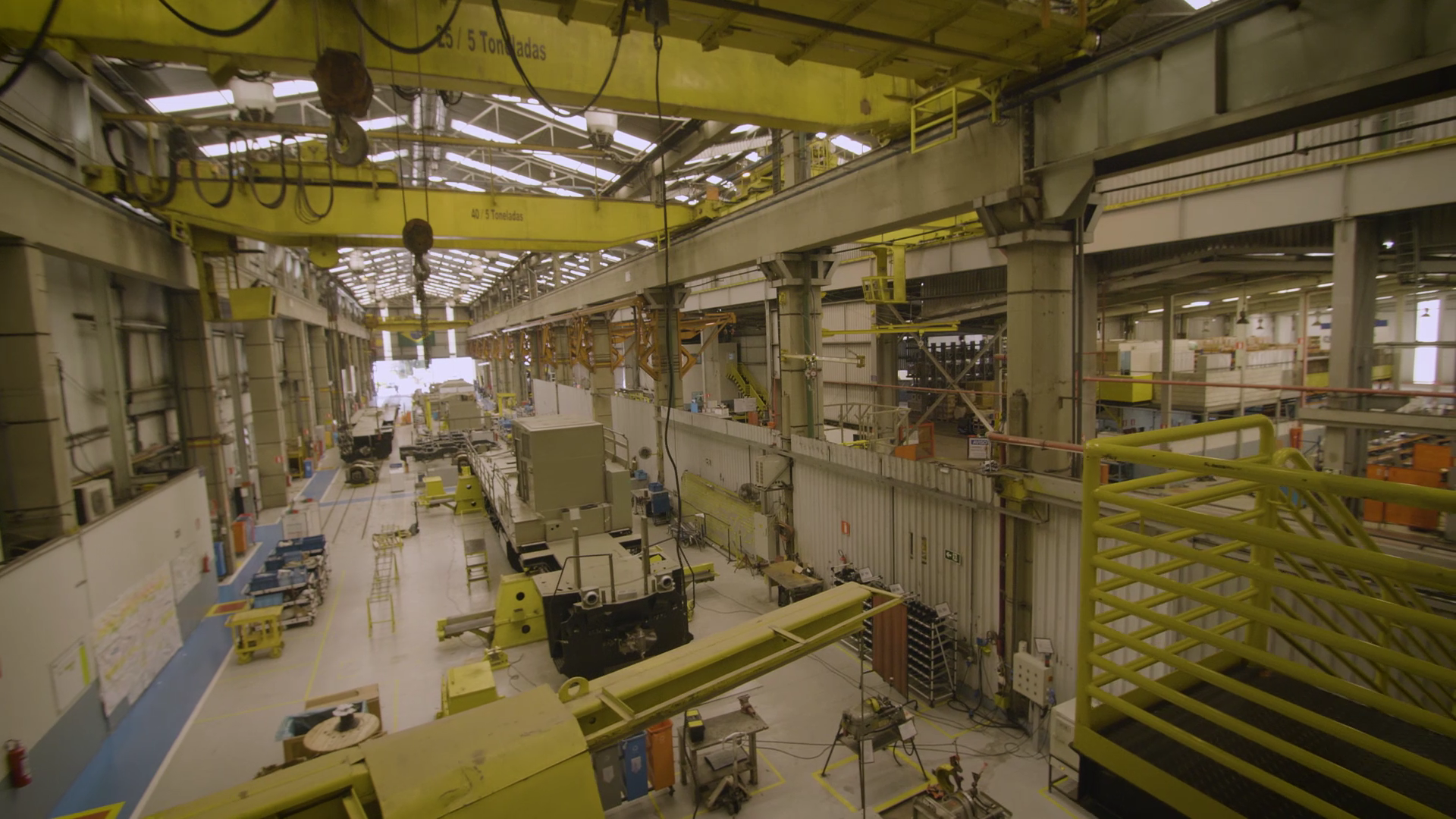

To facilitate the transformation of the plant, the team built a scale model to test the moving line concept. They conducted more than 100 simulations to understand all aspects and interferences that could affect the assembly line. This validation process enabled the team to define the flow, the layout and the ideal space to implement the production system in the factory.

Now, the moving line is operational and moves between 3.8 to 7.2 feet per hour during assembly depending on the production time. The production system also provides real-time visibility to the various manufacturing stages, which fosters a problem-solving culture among the employees to quickly resolve issues as they arise. This attribute makes the line ideal for digital monitoring.

“The mixed-model moving line was connected. This means that several sensors have been installed to show the progress of all locomotive manufacturing steps, so delays, problems and other data are visible in real time through software developed to manage the line. Thus, it is possible to follow the production even remotely,” said Borges.

The new assembly line is part of GE Transportation’s continuous investment in Lean Manufacturing and Brilliant Factory to increase efficiency and improve competitiveness in today’s challenging market. It also supports the Contagem plant’s strategy to become a world-class operation by 2020.

— A GE Transportation news release. Jan. 31, 2018.

The joke of the matter is GE has bigger problems in management than any moving assembly line can ever help solve. That extra 2 million tied up in inventory wasn’t sinking their ship, nor does saving it fix their troubles.

I wonder how many who clicked off the NFL games due to the lack of patriotism by the players equally protested their multi-national employer who displays no patriotism towards it’s birthplace country and all those past generations of engineering feats and sweat equity delivered by generations of Americans that came before them, representing the human investment that made GE into the top locomotive producer. Or is the patriotism standard lowered when the multi-nationals are making deposits into their middle class bank accounts while the NFL isn’t?

Should have been in the USA.

Watch out GE Ft Worth!

“to increase efficiency and improve competitiveness in today’s challenging market. “

Who are they competing with? The ghost of EMD? So much of this efficiency and competitiveness mumbo-jumbo sounds like it belongs in George Carlin’s “Modern Man” monologue.

Yesterday also !!!!!!!!!!!!!!

Did someone forget to put the photos in today’s edition??