“As a 150-year-old member of the greater Pittsburgh community, we have a responsibility to support our first responders during these unprecedented times by allocating resources to combat COVID-19,” said Rafael Santana, President and CEO of Wabtec. “Wabtec and Tronix3D are applying rapid innovation and advanced additive technology to produce critical PPE quickly for hospital staff at this time.”

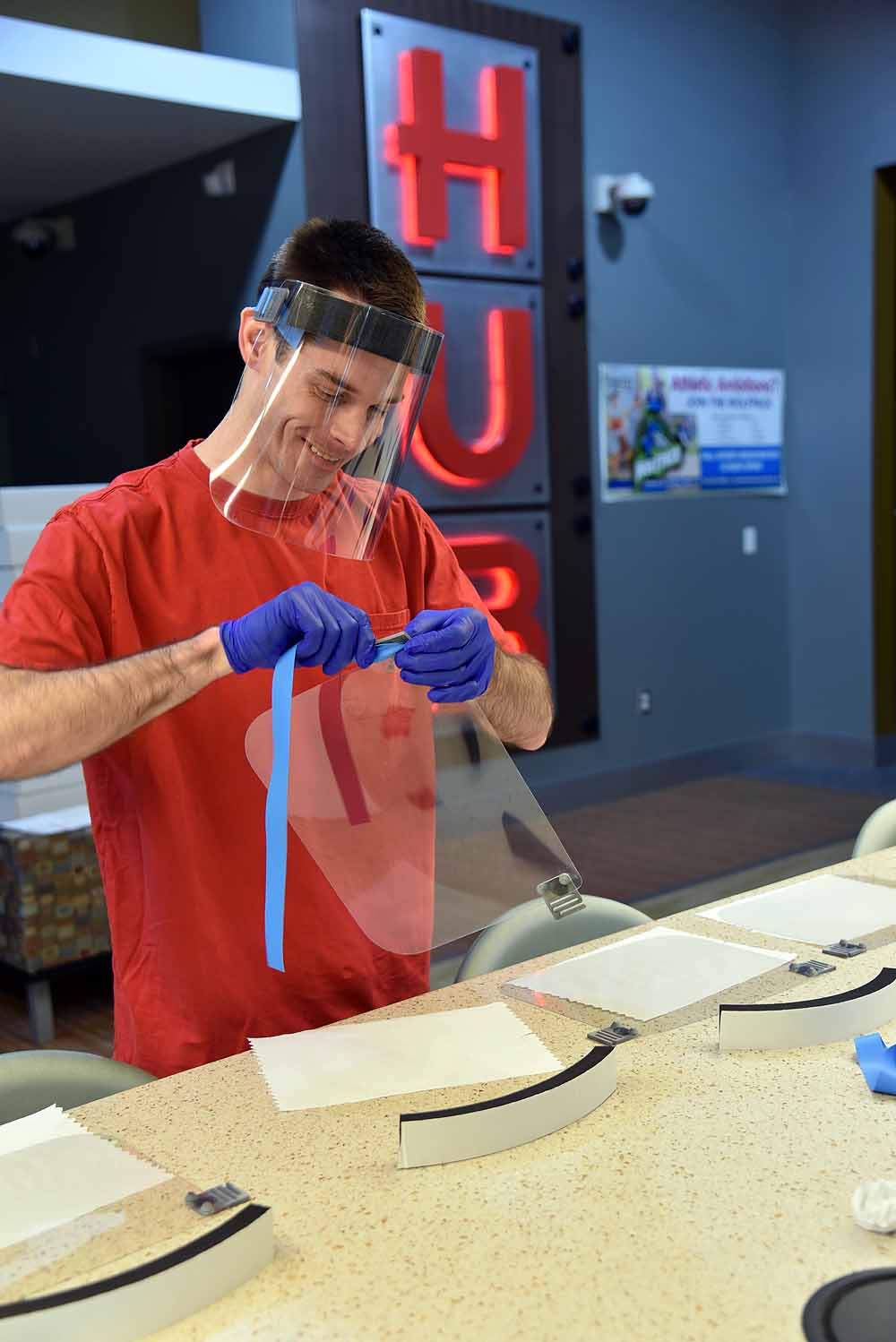

The two companies designed the PPE for fast and easy assembly to facilitate expedited delivery to healthcare workers. Wabtec and Tronix3D are leveraging resources throughout western Pennsylvania to produce the face shields in large quantities. Tronix3D’s team in Mt. Pleasant, Pa., used its 3D printer to build the headgear assembly, which easily snaps onto the clear plastic shields cut at the Wabtec’s Innovation labs in Erie, Pa.

Both companies are donating labor to produce the face shields. Following the first batch of 1,000 face shields, Wabtec will assemble the PPE over the coming weeks at its Grove City, PA plant.

“This partnership is an excellent opportunity to use additive technology for the betterment of our communities in this time of crisis,” said Buck Helfferich, President of Tronix3D. “By working with Wabtec, we can quickly provide local healthcare workers the equipment they require to safely care for those in need.”

Wabtec and Tronx3D plan to produce up to 1,000 face shields a week to support Excela and other local first responders. Both companies are speaking with healthcare organizations throughout the region to assess their needs for PPE as they work to treat patients.

— From a Wabtec news release. April 9, 2020.

Nice gesture. And with practical benefit. That said, after the initial run of donated items, they should be sold for fair market value. COVID-19 is going to be with us for a while. What hospitals and clinics need is a reliable manufacturer who can provide a reasonably priced item, and who can scale up and down with some flexibility.

Super!