WASHINGTON — A coalition of labor unions representing railroad shop workers has asked the Federal Railroad Administration and Surface Transportation Board to take five steps to improve safety and service on the Class I railroads.

In an 81-page letter posted on the STB website this week, the unions say the implementation of the low-cost Precision Scheduled Railroading operating model – which has reduced locomotive and car shop employment by 41% in the U.S. since 2015 – has put the industry “on the precipice of a self-made disaster.”

“Under PSR, the railroads slashed their skilled Shop Crafts workforce to a level that is inadequate for properly inspecting, maintaining, servicing, and repairing all the railroads’ trainsets in accordance with federal regulations,” the unions say. “Furthermore, even when Shop Craft employees are permitted to perform their skilled trade, the railroads pressure workers to ignore defects and defer necessary inspections, services, maintenance, and repairs required under the regulations and which are critical for the safe operation of trains across the Class I’s rail infrastructure network.”

The unions note that the 41% reduction in the number of shop employees greatly exceeds the 13.5% reduction in the active locomotive fleet and the 27% reduction in the freight car fleet since 2015.

Traffic levels, the unions claimed, are at “approximate 2015 levels.” But based on the STB figures the unions cite, both the number of carloads and revenue ton miles fell by 9.7% between 2015 and 2022.

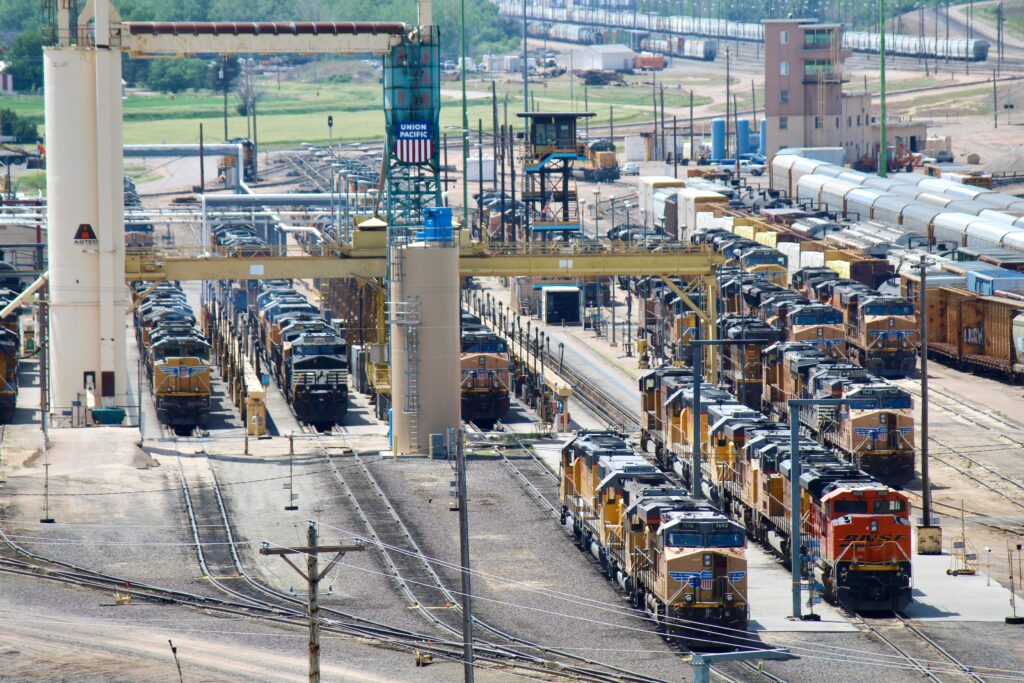

The unions were critical of BNSF Railway and Union Pacific maintenance practices. BNSF, the unions said, was unable to maintain its locomotive fleet with a smaller shop workforce, which raised the number of out-of-service units. UP, which cut 94 shop positions last year, also has not been able to sufficiently maintain its fleet, judging by the 72.6% defect rate the FRA found during an inspection at the railroad’s yard in North Platte, Neb., last year, the unions said.

The unions asked the federal agencies to:

- Mandate uniform training, qualifications, and certification standards for shop workers.

- Create an adequacy of workforce standard to ensure that the Class I railroads have enough workers with the necessary skills.

- Carry out stronger enforcement of safety regulations and standards through more thorough inspections and safety audits.

- Disqualify railroad managers who violate safety regulations.

- Eliminate loopholes in federal regulations that “railroads exploit to maximize profits rather than ensure safety and reliable services.”

Union Pacific said it is reviewing the unions’ letter. “We remain focused on safety and the well-being of our employees and are committed to continuing conversations with each craft to understand their needs and concerns,” spokeswoman Robynn Tysver says.

“Safety will always be our top priority and we remain engaged with our Mechanical teams to ensure we are properly resourced,” BNSF spokesman Zak Andersen says.

— Updated at 1:56 p.m. Central Time with comment from BNSF.

I think we have all been fed more than adequate statistics.

Time to start documenting what is out in the field so action can be taken. We always think “golly, we shouldn’t have to tell a company that requires safety, how to use it”, but then a door stub blows off a fairly new 737MAX in flight.

Just like NS knew about failed hot box detectors, United knew there was a pressure problem in that airframe, but didn’t want to take it out of service to figure it out, they simply put a warning that the airframe wasn’t allowed to fly over water. So the plane was kept in revenue service.

This is the same attitude at railroads. “Just enough safety” but never exceeding. They wait until it is near catastrophic, then and only then, do they do anything about it.

With todays ability to track assets, their use either in ton/miles or age, it should be extremely straightforward to know when certain car types and engine types need inspections and how involved they should be. The “best effort” until it breaks is clearly not good enough.