RICHMOND HILL, Ontario — A structural failure in a bathtub gondola car led to the June 2019 derailment of a Canadian National train in the tunnel between Sarnia, Ontario, and Port Huron, Mich., the Transportation Safety Board of Canada said in a report released Monday, Dec. 18.

A total of 45 cars and a distributed-power locomotive derailed in the June 28, 2019, incident in the Paul M. Tellier Tunnel under the St. Clair River, with one tank car releasing 12,000 gallons of sulphuric acid [see “Cleanup continues after derailment …,” Trains News Wire, June 30, 2019]. While the derailed cars ended up on both sides of the border, the derailment occurred on the Canadian side of the tunnel as the train was heading to the U.S., leading the TSB to assume the lead role in the investigation.

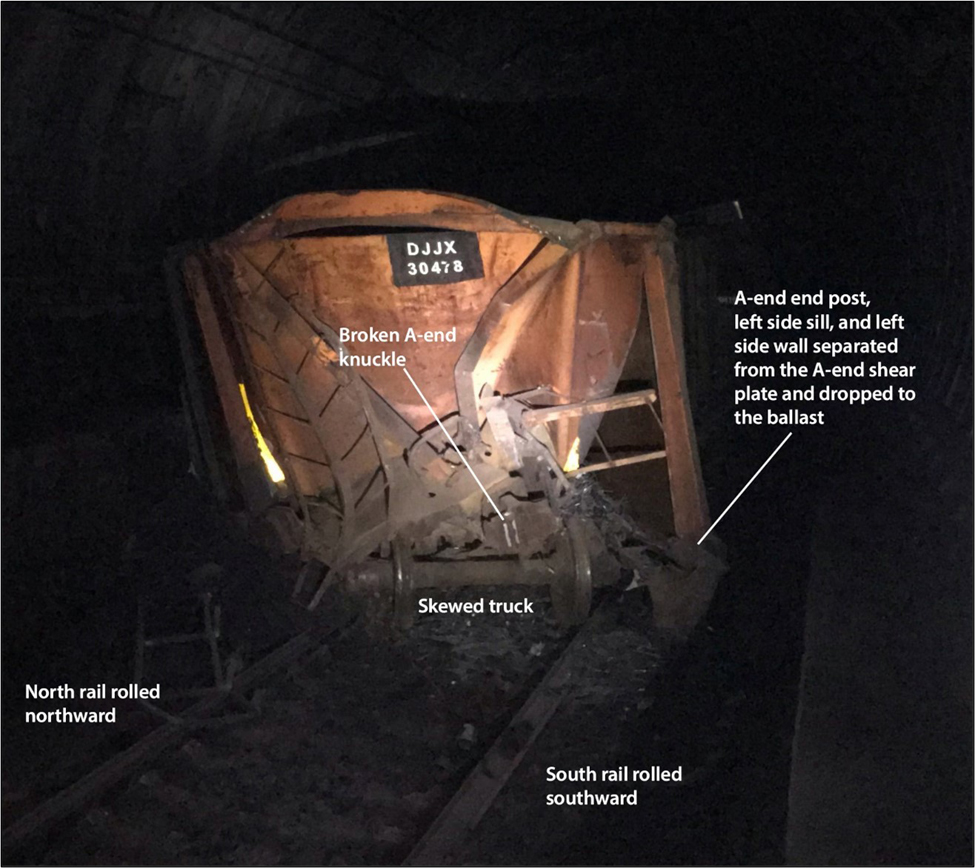

The bathtub gondola had been built in 1978 by Berwick Forge for coal service, but was retired from that use in 2012. It was one of 1,650 cars purchased by the David J. Joseph Co. Rail Equipment Group for use in scrap steel service, and modified for that use, with the reinforcement crossbars that were part of its original configuration replaced with two large steel U channels inside the car. In the derailment, the left side of the car’s A-end collapsed, skewing the A-end truck and causing the rails to roll outward and derail the trailing cars.

The TSB found structural defects were present in the car’s shear plates, stub sills, car body bolsters and side sills, and that steel sections were thinned out due to corrosion. The corrosion likely significantly reduced the car’s buff force load capacity, the board determined. The TSB also found that U.S. and Canadian regulations do not address standards for structural damage such as buckled side posts; ruptured side sheets, end sheets, or tub sections; or extensive cracking and corrosion, so the car’s defects did not prevent it from being interchanged.

The investigation led the TSB to issue four safety advisory letters, two regarding inspection of all cars built by Berwick Forge or bathtub gondolas with stub sills, particularly those used in scrap iron and steel service, that were built in the late 1970s and early 1980s. The others advised Transport Canada to ensure that railways have procedures for train inspections following a derailment in a tunnel involving dangerous goods, and to have adequate practices to manage in-train forces.

In response to these letters:

— Transport Canada contacted railroads regarding the tunnel derailment issues, and worked with the Association of American Railroads regarding the car inspections.

— CN installed permanent visual and audible alarms at the tunnel portals to alert employees of the presence of toxic gases; updated its timetable instructions reflect this installation; and issued a bulletin with new emergency new emergency procedures.

— The Association of American Railroads required inspections of the bathtub gondolas covered, and updated its Field Manual of Interchange Rules to address structural defects of center sills, draft sills, and coupler carriers, and side sills.