The assembled model features die-cast metal and injection-molded plastic construction and is typical of cranes used in major ports and intermodal terminals worldwide.

Cranes and intermodal. Container cranes vary in size and style, depending on the needs of a port or intermodal terminal. Rail-mounted cranes, such as Heljan’s model, are common in dockside locations where they extend over the adjacent ship.

You can learn more about con-tainer cranes in Jeff Wilson’s book Intermodal Equipment and Operations (Kalmbach Publishing Co., 1999; now out of print). Also, be sure to check out Information Desk on page 26 to learn more about intermodal containers.

The model. The crane is made mostly of die-cast metal with molded plastic details. It stands a scale 48′-6″ tall over the top railings, and the girders are 93′-3″ long. The crane has a 59′-6″ span with 34′-6″ of clearance underneath.

The end girders and vertical supports are spaced 38 feet apart, and the top-lifting “head” doesn’t extend, so the crane cannot handle containers longer than 20 feet.

Four motors operate the crane’s functions to move the gantry for-ward and back along the rails, shift the trolley from side to side on the top rails, raise or lower the hoist, and operate the container turning mechanism. All of these motors operate under DCC, so only two wires go to the crane.

The crane has an eight-piece molded plastic baseplate that measures 13 3/16″ x 22 13/16″. The two bottom panels have factory-installed crane rails. There are also several rows of sockets on the bottom panels, similar to building blocks, that the other six panels (with simulated asphalt) lock on.

The model includes two 91/16″ lengths of HO track. However, the baseplate can accommodate five parallel tracks (four under the crane and one adjacent to it). A track-extension kit is sold separately.

The baseplate’s modular design makes it expandable, and a 9 1/16″ x 13 3/16″ extension set is available. However, the instructions state that if the base is expanded there will be some power loss.

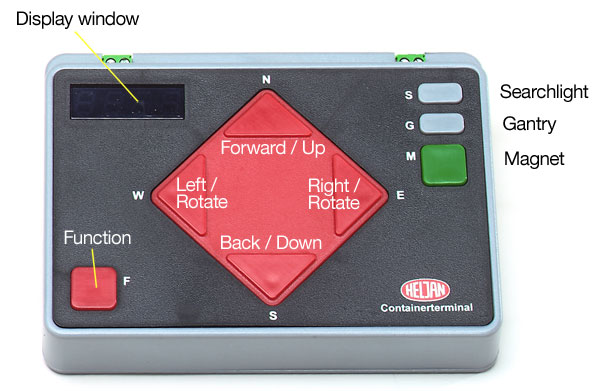

A 16-page instruction booklet contains pictures of the control unit and lists the various buttons (or button combinations) needed to activate the crane’s functions. These functions are labeled in the photo above. Pushing any of triangles will move the crane in the appropriate direction. Holding the function button down works like a shift key to access the second (hoist) movements. The gantry and trolley can be moved simultaneously.

On the right side of the control, three on/off buttons control the hoist spotlight, gantry light, and lifting magnet. In addition, ports on the left and right sides of the control unit are for future use with a joystick or to connect the controller to a computer.

The controller produces DCC commands. A list of adjustable configuration variables (CVs) is included in the instructions. These CVs can be adjusted with any DCC cab capable of programming loco-motives. Most of the CVs adjust the speeds of the various functions.

The crane has nine speed steps that can be programmed for the trolley and gantry motors. Three cranes with different addresses can be operated from one controller.

Moving containers. Each Heljan container includes in its top a thin steel plate. Two flush-fitting nubs of steel are visible on the container roof, but I think the design is a good compromise. If a thicker piece of steel were used, it might strain the winch motor. A dab of paint or weathering will conceal the nubs. Steel plates are available separately for outfitting other brands of containers for use with the crane.

The controller’s commands produced quick responses, and the gantry and trolley moved at real-istic speeds. I lowered the hoist over the first container and activated the electromagnet. A green light-emitting diode (LED) on the hoist lit up to indicate that the magnet was on. I then raised the hoist and moved the container over the car.

Next, I lowered the hoist until the container was in the car before I deactivated the electromagnet and the green LED flickered off.

I repeated the process with the second container, but this time I used the hoist’s rotating feature to rotate the container 180 degrees before I set it down.

Since major ports and intermodal terminals operate around the clock, the Heljan model includes light-emitting diodes (LEDs) under the operator’s cab to illuminate the hoist and six LEDs along the gantry to light the working area. These tiny LEDs produced a surprising amount of light.

A winner. A lot of thought went into the design of this crane, and the easy-to-use controller and wiring make the crane inviting for both newcomers and experienced hobbyists.

Price: $750

Manufacturer

Heljan, exclusively distributed by Wm. K. Walthers, Inc.

P.O. Box 3039

Milwaukee, WI 53201

www.walthers.com

Description

Fully functional plastic and metal container crane

Features

Assembled gantry with operating trolley and hoist

Base plate with factory-installed gantry rails

DCC programming capability

Easy wiring and control

Expandable design

Includes two 20-foot containers with metal plates

Push-button controller

Self-adjusting lift mechanism

I need one

the video is amazing

i can't wait to get this….

The crane looks great in the MR Pictures, but is way to limited in operating features to be used with most present yards where 48 & 53 foot containers are the norm (Garland, TX. Intermodal yard used as referance). If Heljan & Walthers can update those issues then I would be interested in updating my yard to that version. Now back to operating this fork lift truck to load the next container here at the Wylie Yard.

The video demo is awesome. I am looking forward to seeing a real demo at a train show. If it does what it claims to do it will be a great addition to my layout. I am however worried about the price.

I saw this unit demonstrated at the recent train show at state fair park in West Allis Wisconsin , I must admit it is quite impressive but it seem very problematic when making various picks.I don't think it is worth the money.

I have one and it will lift 20,40,48 and 53 ft. containers. What I did to modify these containers as a test was to use K&S .005 stainless steel strips and glue them on the roof of the containers. I all cut small cylinders of 5/16" steel rod and inserted two in the roof of an undecorated container. The Heljan electromagnet is strong enough to lift all without a problem.

I forgot to mention, I repainted the Heljan containers and utilized Microscale container decals to re-letter the containers. Overall this is one "cool" items; almost like a video game for your layout but scale and functional!

I have been waiting for one of these for a very long time. Now all I have to do is find the money and the space. I will have at least one in the future. I have seen this model at a show to. It is incredible!

I've seen the Heljan video of this crane in operation, and it's beautiful. But limiting the container size to 20' seems to limit the usefulness of the entire thing. Most of the containers and trailers that I have are 40', 48', or 53'. Is the limiting factor the torque available to the lifting motors? Ths sheet steel plate wouldn't need to be any bigger for a larger container, and the plastic containers' weight differences are almost negligible when compared to the steel weight.

It looks great & works well but is still outside my budget at this time.

I wouldn't mind having one, but for $750, I would have to do a lot of soul searching.

I have one of these models, and I had a problem with the wire connection at the track which the gantry rides on , so I replaced the track with #83 code track which came in 36 inch lengths which is double the length of the platform and solder the wire to the track. End of problem. It is pricey , but I waited until it went on sale for $550.00 You will have no problem spending hours loading ,unloading and switching cars. I find it a great model

Just finished installing it, I noticed it needed the surface to be very flat. I recommend ensuring there is some timber under the tracks for the loader to keep the surface flat and level. Other than that it works great!

It is a bit pricey, but it is a leap in smooth operation compared to the Brawa model it replaced on my layout.

It looks very intresting. I'd sure like to get my hands on one one of these days, but I'd like to pay a little less.

After experimenting for days now with steel & iron strips of ALL sizes / thickness INSIDE the top of the container, I am sick & tired and need some suggestions.

The HELJAN magnet did not lift ANY combination I tried. I am certainly NOT going to cut these little round holes into the top of my containers nor glue a metal strip ON TOP of the containers. That looks awful and will ruin any prototype resemblance.

Has anyone a suggestion? Should I use MAGNETS inside the containers?

A direct reply to

raslerb@bodorasler.com

would be appreciated as well!

Thanks

Bodo

Outstanding product, well planned, operates flawlessly. Can be operated with a DC or DCC layout. The controller is excellent as it lets an operator move the trolley and gantry at same time. Adds a new dimension to operating the layout.

I have purchased one of these cranes and have found it to be even better than I expected. The fact that I can program it to suit my specific needs and operate it from my DCC system is a big plus for me. There is no problem lifting the larger (up to 53') containers. You only need to swing them round 90 degrees to pass between the gantry legs. Best piece of HO equipment I have ever purchased.

This is a model by a european designer and on their website they do show it lifting and moving a 40' container. You simply have to turn the container to move it between the uprights. Also keep in mind that the standard size for international containers are 20' 40' and 45'. It's our American doemstic containers that are 48' and 53', and these are *never* sent overseas Being based on and ship loading european container crane the limits in container size are fairly reasonable.