Q: I recently started working again on my HO scale layout, which features a Digitrax Super Chief Starter Set and Bachmann E-Z Track. I cleaned all of the track and have been testing locomotives. One of the units, an Athearn Genesis HO scale Electro-Motive Division GP38 that has not been used in some time, will not run in reverse. When I set the throttle to reverse, it shorts out power to the entire layout. It runs forward decently. Any thoughts on what the issue might be? — Jochen Ideker

A: When diagnosing a stubborn diesel, it’s good to get more than one perspective. For this question, I reached out to a couple of people. Model Railroader Contributing Editor Larry Puckett responded, “First, even though your other locomotives run fine, the GP38 may still require cleaner track. At a minimum clean a section a couple of feet long and see if that works.

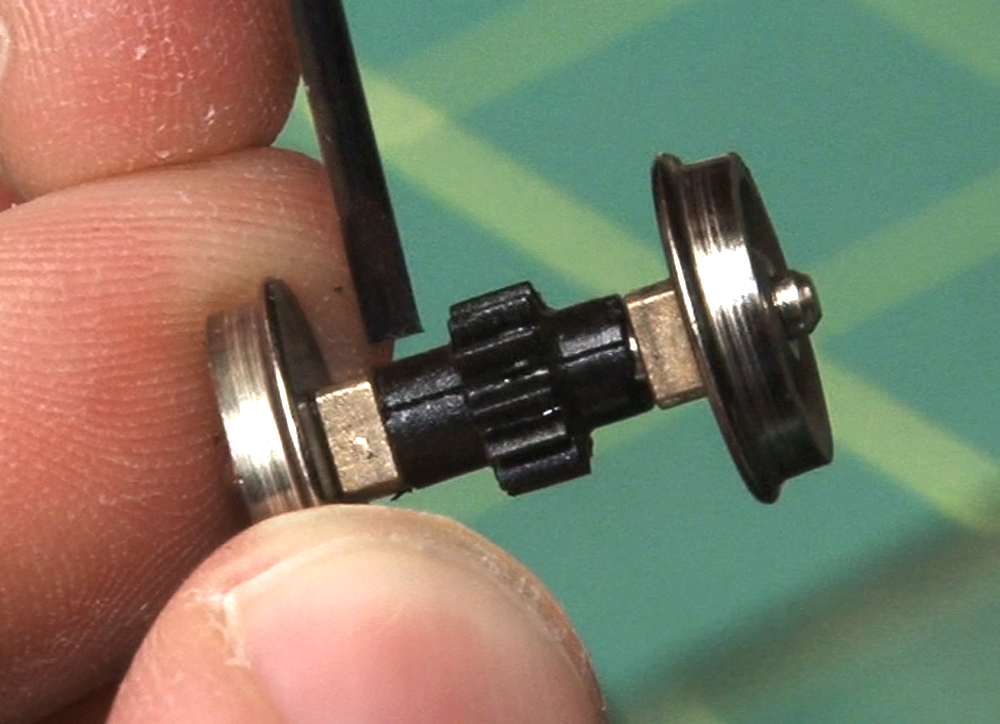

“Also take a closer look at the wheels to make sure they’re very clean. If the problem persists, check the lubrication of the axle bearings and the gears. Lube tends to dry out if a locomotive is stored for an extended time, and coagulated lube may bind and cause the motor to overload the decoder. On some old engines I’ve had to completely disassemble the trucks, remove all the old lube, and reapply fresh grease and oil.

“Another possible solution is to remove the shell and check for any wires catching in the mechanism or rubbing on the frame. This can cause wear spots in the insulation and lead to shorts.

“Finally, try to reset the decoder to factory settings by programming CV8 to a value of 8. This has worked a number of times for me and others in your situation. Remember that the address will likely reset to a value of 3 and any changes you have made will be lost.”

Model Railroad Planning Editor Tony Koester asked for the opinion of Tom Schmieder, owner of Real Sound Solutions. Tom replied, “First off, I’m suspicious of the press-on wire clips that Athearn uses, not only for wires connected to their motherboard, but for the power pickup wires connected the same way to the trucks as well. Not that this is necessarily the problem here, but a loose wire from those connections could be.

“If I were working on this engine, I would be looking at the motor and associated wiring to find out how the motor torque in reverse causes the short. Perhaps there’s a wire that’s loose and is too close to one of the drive shafts. It could get snagged, pulling on the wire and causing a short in the one direction. I’d check all wiring and clearances around moving parts and watch for the problem there. I’d also replace all of those press-on wire clips to the motherboard and trucks with soldered connections for better overall reliability. If that doesn’t uncover the problem, perhaps there is a problem with the motor itself.”

Send us your questions

Have a question about model trains, full-size trains, or toy trains? Send it to AskTrains@Trains.com.

Thanks Cody I will remember that. My brothers and I use some of these methods because I own a lot of locomotives and I am getting several layouts soon. Gunk in the gears? use a paper towel, freight car and locomotive wheels sticking? use a pencil, trip pin too low? Use needle nose pliers, locomotive and freight car too light? Add weight or use some weights out of a tackle box, and locomotive shorting on switches? Replace the switch or clean your gears that is the leading cause of why these things get stuck.