Q: I’m having some N scale locomotive electrical problems. My 6 x 8-foot layout is powered by NCE Digital Command Control. My locomotives will roll a few inches, then stop. If I give them a push, they stutter on/off, on/off, on/off. When the locomotives are moving, the block occupancy detector’s light-emitting diode (LED) is on, as it should be. But when they stop, the LED is off, so it’s not sensing the locomotive at all. The layout is divided into two power districts and eight detection blocks; the problem occurs on all of them.

I have cleaned the track and the wheels. I have performed a factory reset on the decoders. I switched one power district to a Digitrax Zephyr controller, and the problem still existed. I put an RC filter (snubber) on each block. The power supply for my boosters is switchable between 12V and 13.5 volts; I tried both. I used my DCC Specialties RRampMeter II to measure track voltage and got a constant 11.8 or 13.5 volts on every block, depending on the power supply switch selection. All track joints are soldered.

In case the problem was in my wiring, I cut the track feeders from all the existing wiring and strung a brand new power bus for the main line in one of the power districts. I wanted to try a clean power source free of block detect circuits, filters, and everything else. But this didn’t solve the problem, either.

To add to the mystery, I have one Bachmann steam locomotive that runs mostly trouble-free. But even it stops once or twice in a full lap. My other locomotives are Broadway Limited, Atlas, and one unknown with a Digitrax decoder. All suffer equally. Please, if you could offer any advice, I would appreciate it. My layout is useless in its current state. Thanks for your time. — Ron Chaffee

A: Ordinarily I’d tell someone with problems like yours to clean their track and their locomotive wheels. But you’ve already done that. Next, I’d suggest testing the layout wiring. But you’ve already done that, too — in fact, you’ve gone above and beyond, replacing your power bus and even swapping out DCC base stations. And you’ve soldered your rail joints, as I would also advise. Ordinarily at this point I’d throw up my hands and say I can’t help you. But there are some clues in your letter that intrigue me and may offer a solution. So let’s dig in.

If current were still flowing through the locomotive’s circuits but the gears were binding or the like, the block occupancy detector LED would stay on when an engine stopped. The fact that the LED turns off confirms that it’s not a mechanical issue; the power is definitely being interrupted.

This power loss to the locomotive is intermittent, but you said that the RRampMeter returns a constant voltage. So the power is reliable from the DCC base station to the rails. That isolates the problem to the locomotives. The fact that you do have one semi-reliable locomotive adds credence to the theory that the problem isn’t the layout.

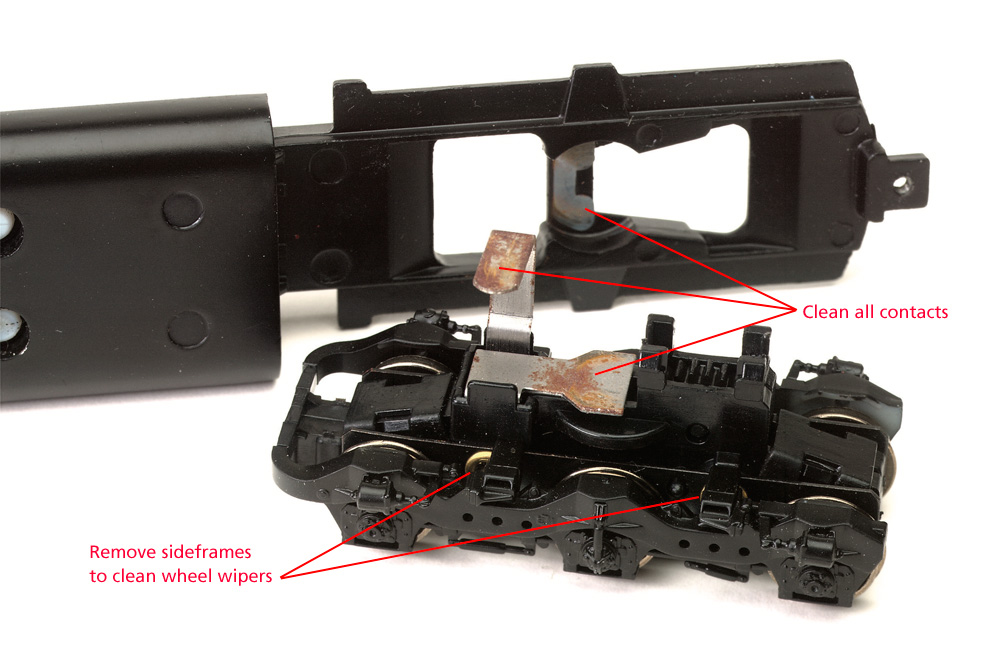

Let’s assume that current is getting reliably from the rails to the wheels. The next place current could be dropping is the pickups that convey the electricity from the wheels to the DCC decoder. There are basically two kinds: wipers that rub against the wheels or axles, or little conical contacts that fit inside the truck sideframes and pick up current from metal axle tips. Both can over time corrode, carbonize, or pick up dirt that interferes with their function. Open up your locomotives and check those contacts. After manually removing any dust bunnies, clean the contact surfaces with a pencil eraser or isopropyl alcohol on a Microbrush.

If the electrical connections from the trucks to the frame or decoder also relies on wipers, clean those, too. Heavier rust like you see in the picture above might require work with a sanding stick. If the pickups are instead hardwired to the decoder, check that wiring, too. It’s not very likely that the solder joints could go bad on all but one of your locomotives simultaneously, but it can’t hurt to look at them as long as you have the shell off. And while you’re in there, clean the axle bearings and gear towers and give them a drop of plastic-compatible light oil.

You didn’t say what kind of locomotives are giving you trouble, but you specifically mentioned that the one that’s working better is steam, so I’d guess the others are diesels. And if you’re modeling the steam-to-diesel transition era, I’d also be willing to bet that your steamer is a longer model that, between the drivers and the tender, has more pickup wheels than your diesels. That would explain why it’s operating more reliably while your eight-axle diesels are having trouble.

I would bet almost anything that there’s something on your track — metal filings, magnetic or conductive material in your real-dirt ground cover, or just plain old dust — that’s getting attracted by motor magnets or static electricity and accumulating in your locomotives’ electrical pickups, bearings, and gears.

For more tips on getting the most out of your motive power, read Jim Hediger’s Workshop Tips column from our December 2012 issue, “How to tune up your diesel locomotives.”

Good luck tracking down and curing your locomotive electrical problems.

Send us your questions

Have a question about modeling, operation, or prototype railroads? Send it to us at AskTrains@Trains.com. Be sure to put “Ask MR” in the subject.

I just signed up and was reading this article, It looked like a similar issue I recently had, was about to pull my hair out, couldn’t find the problem. I started taking locomotives from the tracks and tried the power again believe it or not it started working again, so now I had to try one by one my locomotives again. Low and behold my BLI was the culprit, it had a short in it. I had pulled wires, disconnected things, checked my turntable etc.etc. So after all this, I was glad that I found it. I see this man his frustration and hope it is solved.