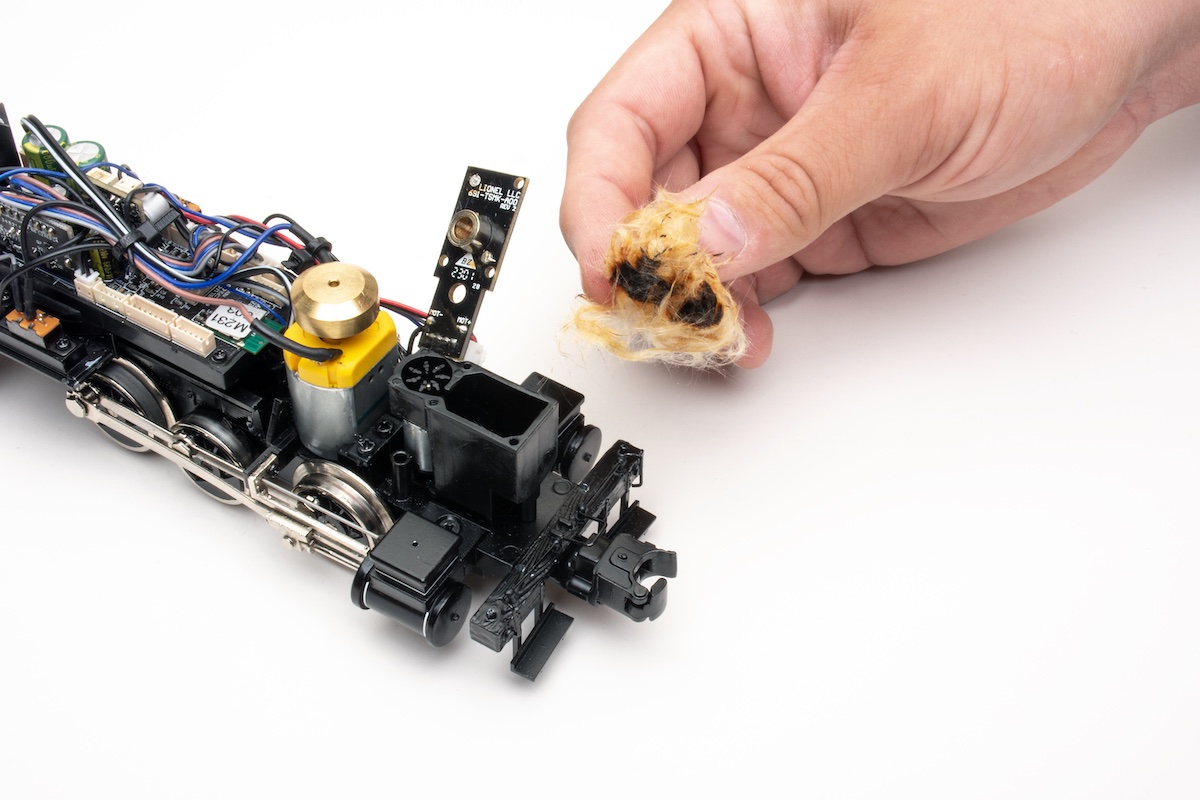

Is your locomotive struggling to produce a good amount of smoke, even after cranking up the smoke volume and adding fluid? While it’s not the one-and-only culprit, a charred smoke wick is a common problem.

The wick is a strand or braided fiber glass material in the smoke unit’s heating chamber. It generates the smoke effect when heated and properly moistened by the heating element and smoke fluid, respectively. If the wick isn’t moist enough, it will dry to the point of charring. At that point, you have two options: turn off the smoke unit; or enhance your skills by changing out the wick, especially if this is your first time.

Some dissembly required

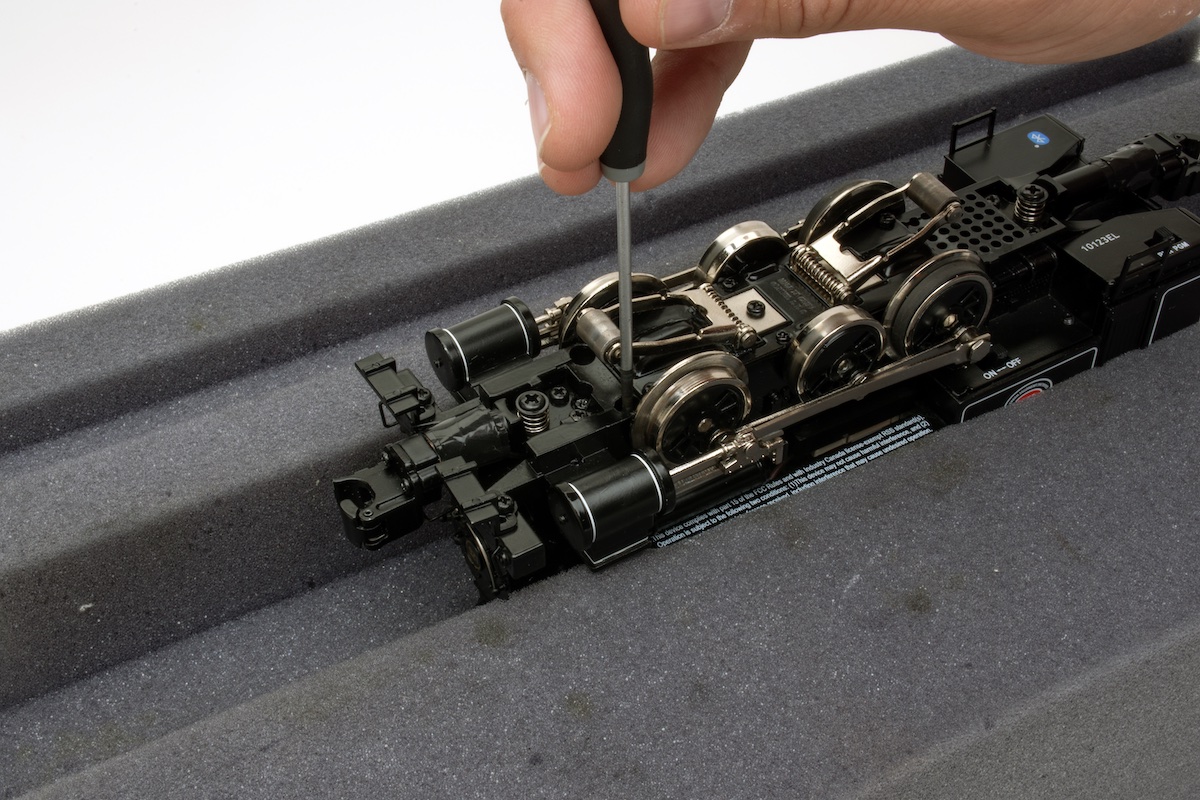

You’ll need to take your locomotive apart to access the smoke unit. Begin by removing the body from the frame, which is normally held by about four body-mounted screws on the underside (Refer to your model’s manual if you’re unsure of the location and number of screws). If you’re taking apart the model for the first time, equip yourself with quality, size-correct screwdrivers; and keep track of which screws and unplugged wires go where for the future reassembling process. Here are some tips from Cody Grivno on disassembling locomotives.

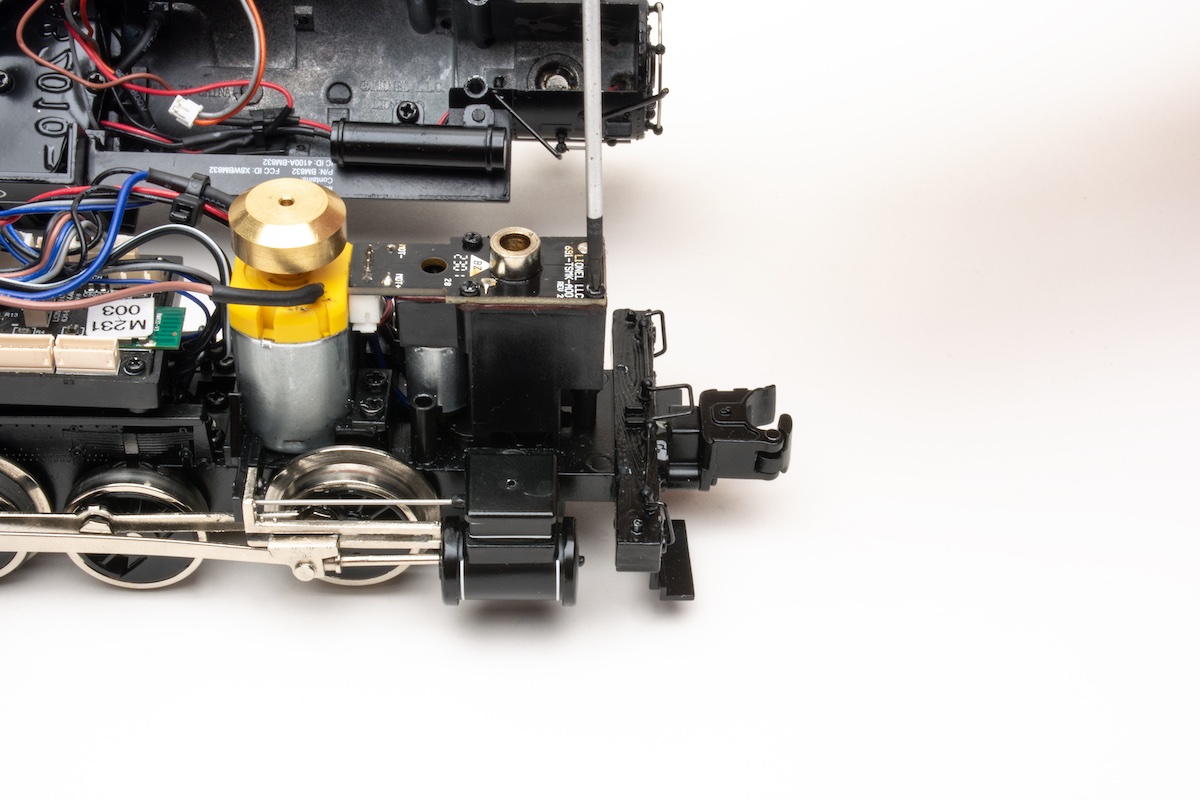

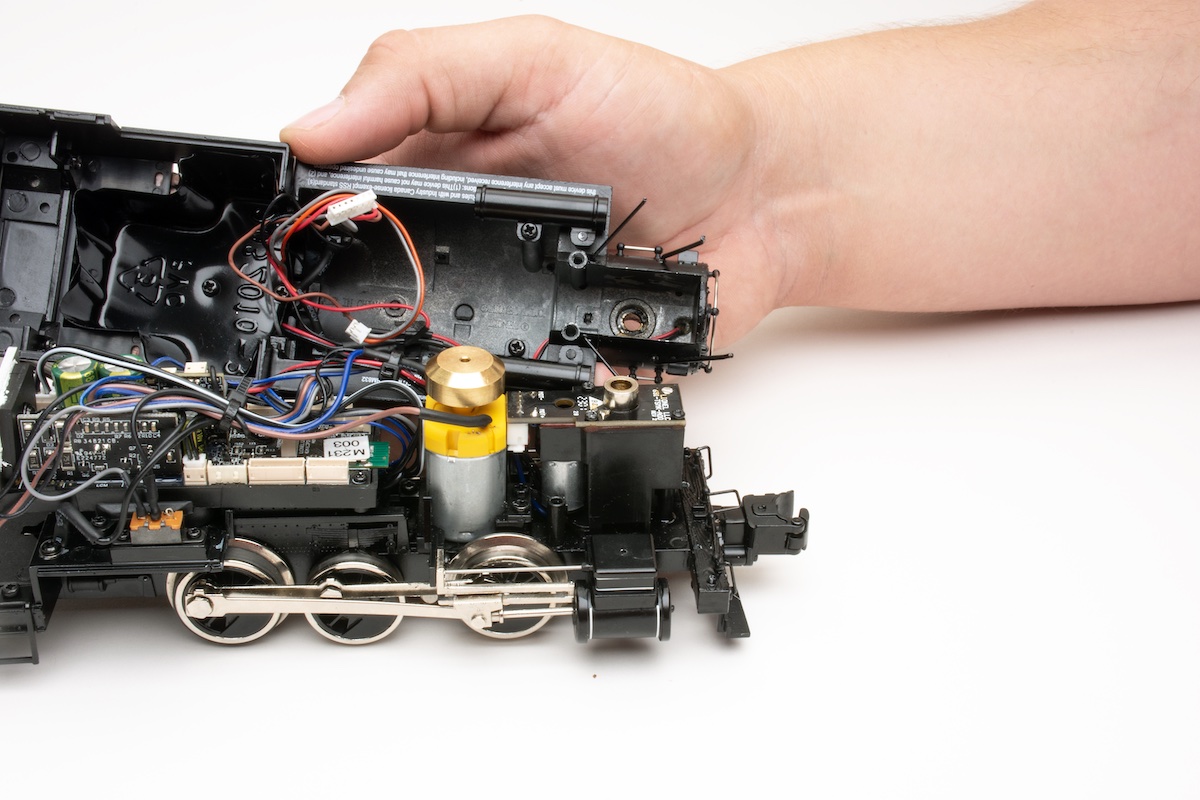

When separating the body from the frame, gently place both components next to each other to analyze the location of the smoke unit(s). Some units are exposed on the frame itself, while others are mounted deep within the body, requiring you to unplug wires and remove additional mounting screws to gain access. Steam locomotives with additional smoke effects (such as a steaming whistle) may have multiple units, or sometimes just one with feeder tubes running to different stacks, exhausts, and holes in the body.

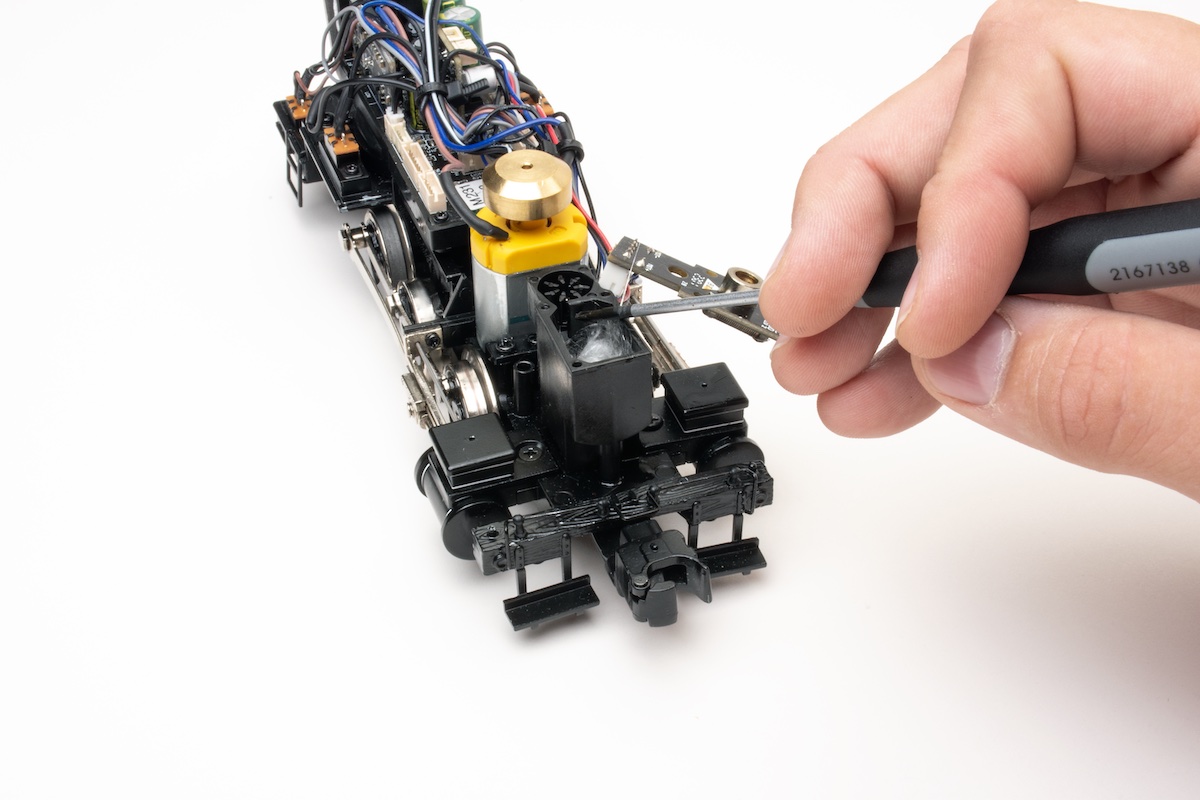

The top of the smoke unit’s heating chamber is sealed by a gasket and inspection cover, held in place with Phillips screws. These screws can be removed, along with the cover and gasket, to reveal the charred wick inside.

Wicked tips and tricks

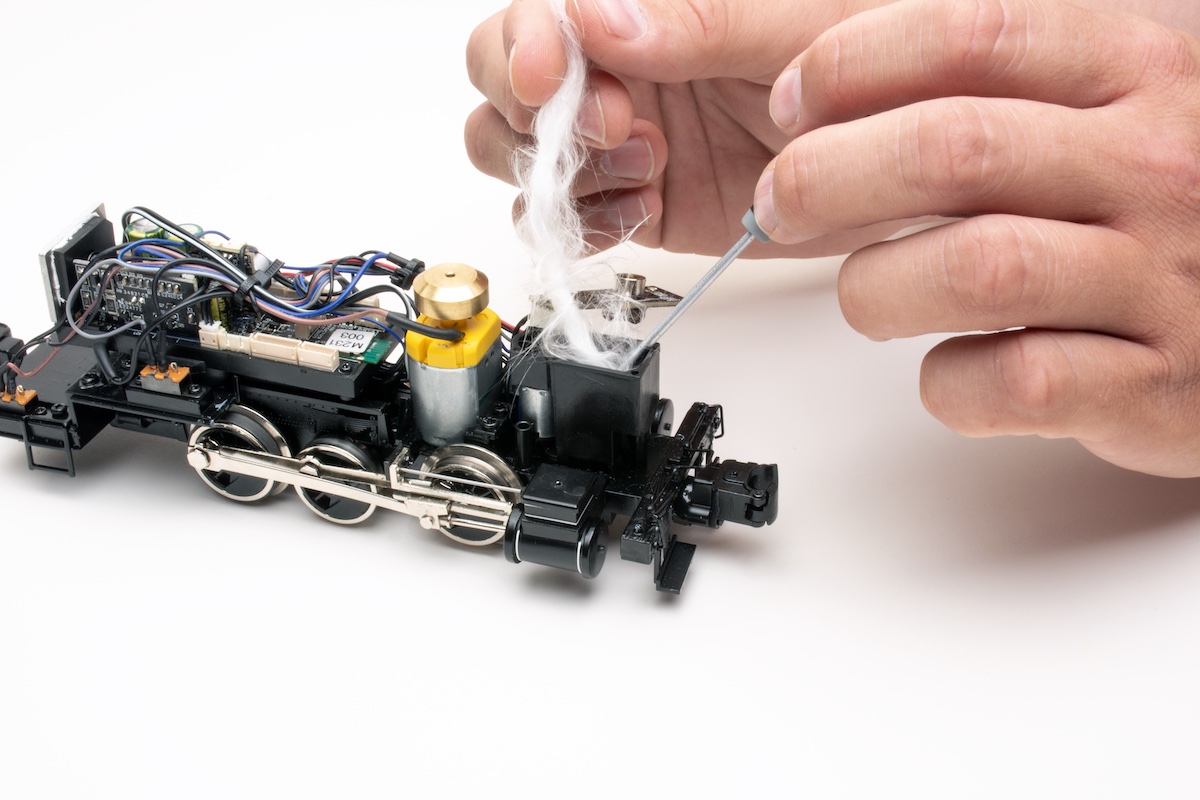

Fiber glass wick replacements are available from Lionel Trains (cs-691SMKP008-p), MTH Electric Trains (AA-0000001), and third-party suppliers from both online retailers and brick-and-mortar hobby shops.

A 12-inch, fluffed-up strand of new wick is usually more than enough to stuff back into the heating chamber. MTH locomotives traditionally have the wick pinched between two heating elements and dangling at a proper length into the chamber. Another trick I picked up from our good friends at Sommerfeld’s Trains & Hobbies is cutting the wick into smaller 1-inch strands and stuffing each one in one at a time to get a good feel of how much is enough.

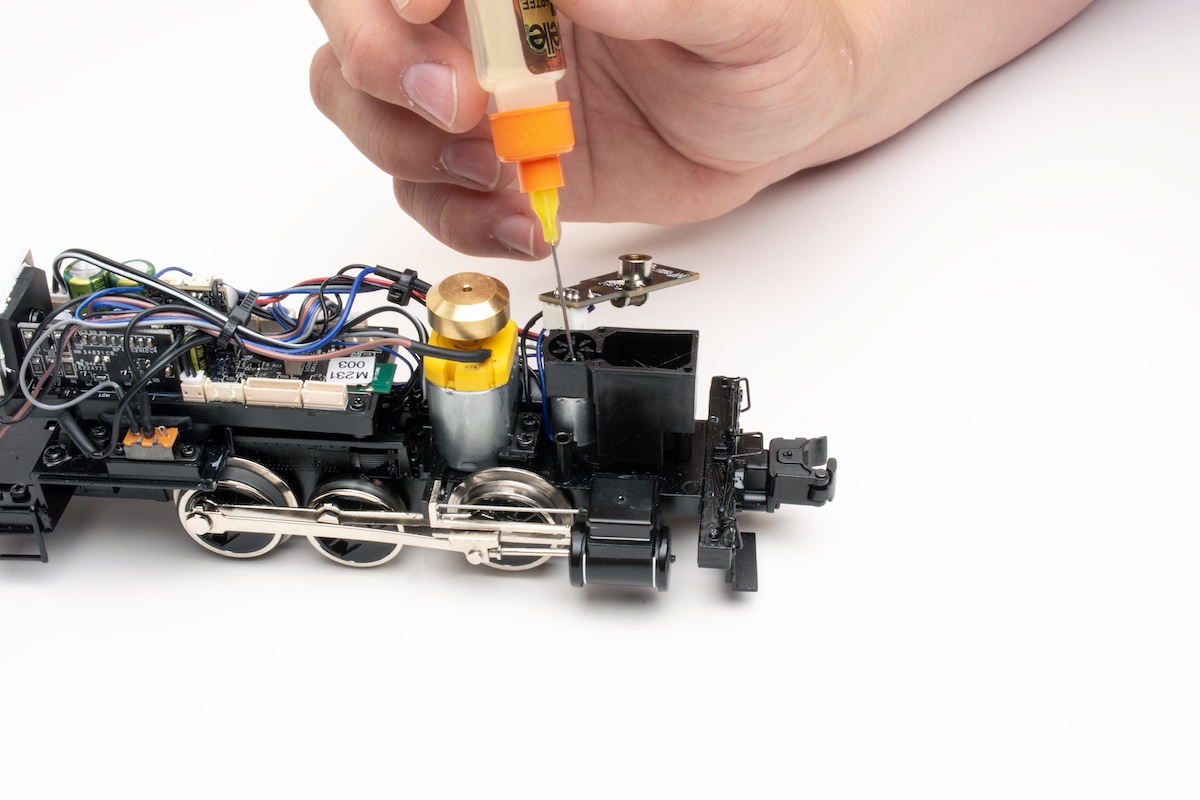

Regardless of how you insert the new wick, ensure the airway between the fan, chamber, and exhaust port is open and clear of any obstruction, while allowing the wick to make contact with the heating element. Give the inserted wick a good soaking with smoke fluid before closing the heating chamber.

Leave no stone unturned

A charred wick isn’t the only cause of poor smoke output. While doing the replacement, take the opportunity to inspect and test other components like the heating element and fan motor. (Note: If you have an older Lionel starter set or TMCC locomotive with a wick sleeve wrapped around the heating element, that can be disregarded.) Given a chance, provide temporary power to the fan motor to make sure it’s operational and spinning in the correct direction towards the airway that’s heading to the heating chamber.

You should also perform routine maintenance on the motor itself. A drop of light oil lubricant — preferably Labelle No. 107 — on the motor shaft goes a long way in ensuring reliable performance and reduced fan noise.

When reassembling the smoke unit and the locomotive overall, patience is a virtue. Check and double-check to make sure screws are tightened, unplugged wires are firmly reconnected and not pinched when the body is lowered back onto the frame, and the unit’s exhaust port and feeder tubes are properly aligned and sealed.

By leaving no stone unturned, the amount of smoke produced by the re-wicked and maintained smoke unit will be greatly improved. However, be aware that changing the wick in a modern fan-driven smoke unit won’t always be a permanent fix. The replacement will eventually char as well, no matter how much smoke fluid you fill the reservoir or how often you do so. I recommend viewing this process as part of your locomotive’s routine maintenance to extend its service life.