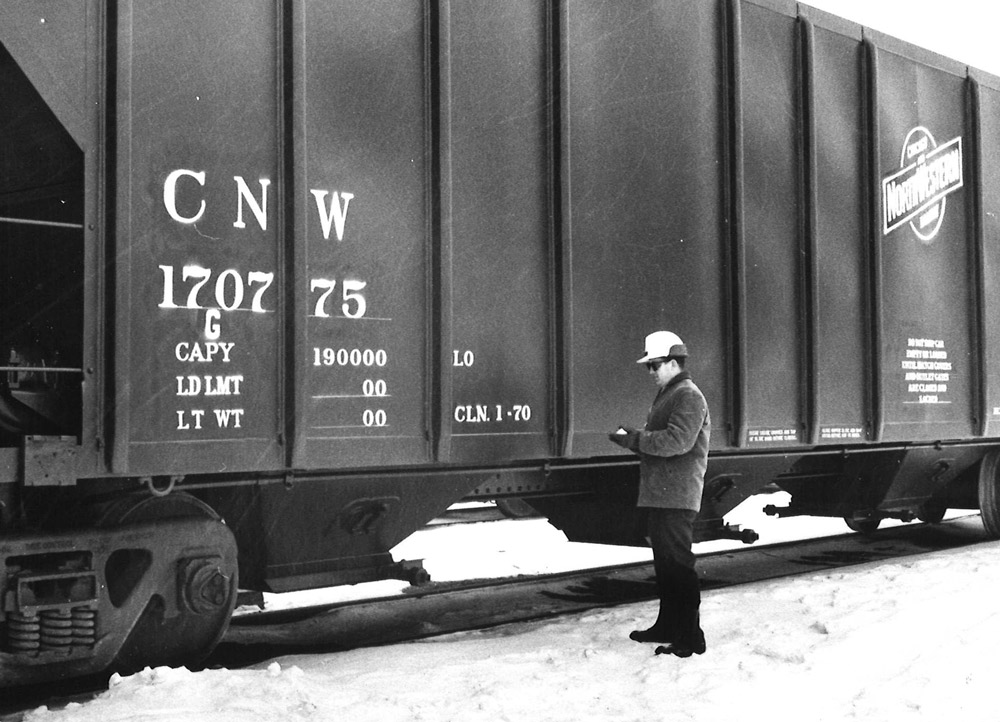

C&NW

In 1981, I was Director, Freight Car Engineering, for Berwick Forge & Fabricating, a railcar manufacturer. The company decided to start producing grain covered hopper cars, which seemed to still have a significant market. I developed a prototype car that weighed more than desired, reducing the available load capacity. Although we stenciled the car with a lighter weight for the advertising photos, production cars would have to be several thousand pounds lighter.

I devised a roof design that relied on the curvature of the roof sheets to provide the necessary stiffness in place of the steel angles used to support the straight roof sheets of the prototype car. Our calculations showed that the curved roof, along with other modifications, would bring the car’s weight down. We eventually received an order for 500 cars from North American Car, a major car-leasing company that in turn leased the cars to the C&NW. The cars were to be built in our plant in Renovo, Pa., a former Pennsylvania Railroad shop. When the first one was completed, we held a sample car inspection for North American and C&NW personnel.

Sample car inspections are common in the freight-car industry and provide the customer with the opportunity to inspect a representative car, make comments, and request changes before large numbers of cars are completed.

C&NW was represented at the inspection by two men I will refer to as “Don” and “Ira.” Both were experienced, knowledgeable men who were well known and respected in the industry. Ira packed about 350 pounds onto a 5-foot 9-inch frame, and Don had the same proportions but, being over 6 feet tall, tipped the scales at more than 450 pounds. I considered both to be personal friends as well as professional colleagues and looked forward to seeing them at the inspection.

Since Renovo is far from the nearest commercial airport, North American flew its representatives for the sample car inspection and those of the C&NW on a corporate jet into the Piper Aircraft plant at Lock Haven, Pa. The door on the plane was hinged on the bottom and, as it swung down to form the stairs, was supported by two cables which also served as handrails.

Ira was the last person to leave the plane and, as he stepped on the door, one of the cables snapped. Fortunately, he was not hurt, but the hinges of the door were damaged. For the rest of the day, Don and Ira argued semi-seriously about who really broke the door. Don’s logic was that nothing happened to the door until Ira stepped on it. Ira countered that the cable had been overstressed when Don got on the door and that anyone who followed him, regardless of weight, would have snapped the cable.

When the visitors arrived at the shop in Renovo, they conducted a thorough inspection of the car, all its components, and the production line. Everything was going well when Don and Ira decided to inspect the roof, loading hatches, and running boards. For their size, both men were surprisingly nimble, and they climbed up an end ladder quickly.

As it happened, the shop building had trusses supporting the roof, the bottom members of which were about 6 feet above the hopper car roof. Holding onto the roof trusses for stability, Don and Ira started to jump up and down in unison on one of the running boards. The car roof was designed to meet the AAR design-load standard of 15 pounds per square foot plus a 300-pound concentrated load, but was not designed to handle 800 pounds on the hoof jumping up and down. To say that I was nervous would seriously understate my level of concern.

However, after it became apparent that the roof was holding up just fine (with perhaps a little permanent deflection in the running board), I began telling everyone that I had known all along that there would be no problem. And, having already passed the acid test, the roof held up very well after the cars entered service.