If you run steam locomotives on your model railroad, you need a steam engine terminal. Even if you don’t have room to model one, your model locomotives must get serviced somewhere off layout. But there are a lot of good reasons to model a steam engine terminal.

First of all, and most important to some, they’re vital to the prototype. A steam locomotive can’t go very far without a place to top off its tender, dump its ashes, get inspected and oiled, and have its boiler scrubbed out now and then. And that’s not counting the odd repair and wheel-truing. So a steam layout isn’t complete without one.

Second, all those functions require operation. Getting the railroad’s locomotives ready for work in the morning and putting them to bed at night is a lot of work. The engine has to visit the coal tipple, water tank, sand house, and maybe the wash rack before heading to the ready track. After its work is done, there’s another list of tasks to complete before it takes a spin on the turntable and backs into the roundhouse for the night (or the RIP track, if it fails inspection). An engine hostler’s job is never dull. Plus, the terminal has to receive coal (or oil) to fuel the locomotives, sand, lubricants, and repair parts. The terminal might have its own powerhouse that will also need fuel by the carload.

In fact, there’s so much operating potential in a steam engine terminal that one can be a layout all to itself. Check out Kent Johnson’s O scale 4 x 8 plan in the Track Plan Database (from our article “More fun with 4x8s” in the March 2011 issue).

Finally, there’s the scenic aspect. Steam engine terminals are typically loaded with interesting details like workman figures, tool racks, welder’s gear, junk piles, barrels, old ties, and spare parts like wheelsets and couplers. Not to mention the locomotives themselves! What better place to proudly display your finely detailed locomotive models?

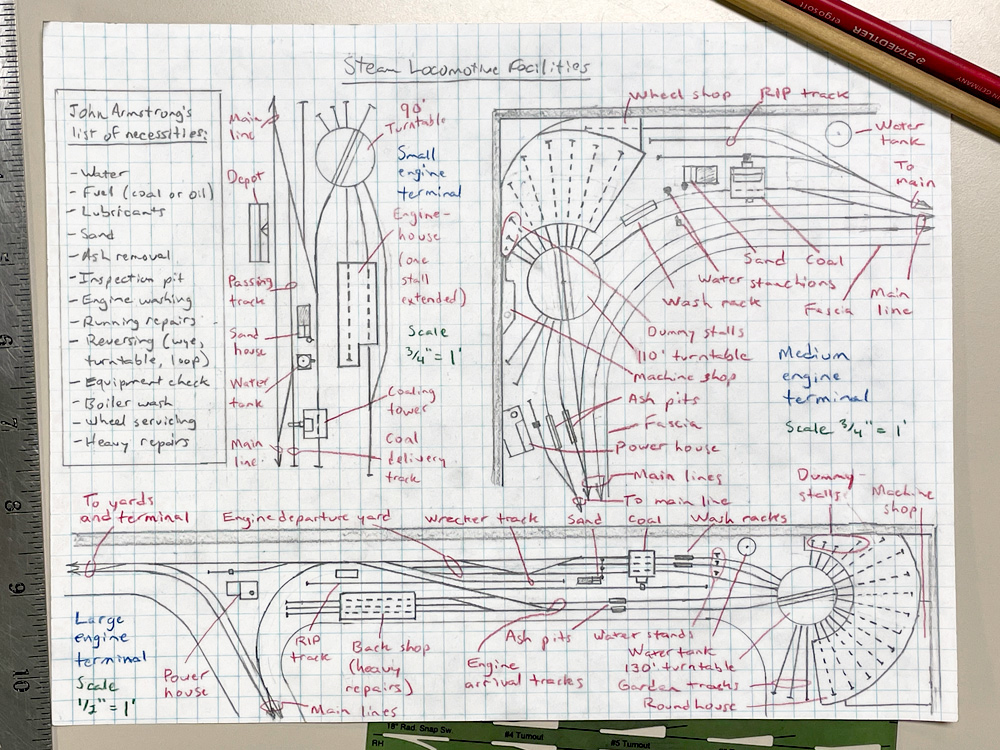

So what should be included in a comprehensive model of a steam engine terminal? John Armstrong included a list in his seminal book Track Planning for Realistic Operation (Kalmbach Books, out of print but often available used online). Tops on that list, which is included in the image above, are sources of water, fuel, and sand; ash removal and underbody inspection pits; turning facilities (a turntable, wye, and/or loop); a shed or roundhouse to perform maintenance; and more. Not all these features need be included in every steam engine terminal, but you need the basics.

My exploration of steam engine terminal track plans resulted in the record-holder for the most crowded sketch I’ve ever produced. So I’ll break out each plan into a separate image to discuss it.

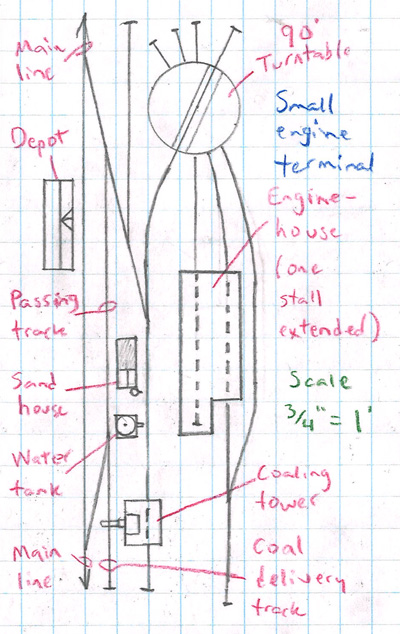

A small steam engine terminal

A facility of this size is just a few steps up from the trackside water tank and coal tower. Including a sand drying house, a small turntable (indicative of the early years of steam), a two-stall enginehouse, and engine storage tracks elevates it to the status of an engine terminal. It lacks the facilities you’d find at a larger terminal, but it’s enough for a small layout or the end of a branch line. The plan in my drawing is selectively compressed to fit on the page, so if you have the room, lengthen the passing track and turn the stub tracks off the turntable into locomotive storage tracks. The spur between the turntable and the main could be used to store idle locomotives, cabooses, maintenance-of-way cars, or snowplows.

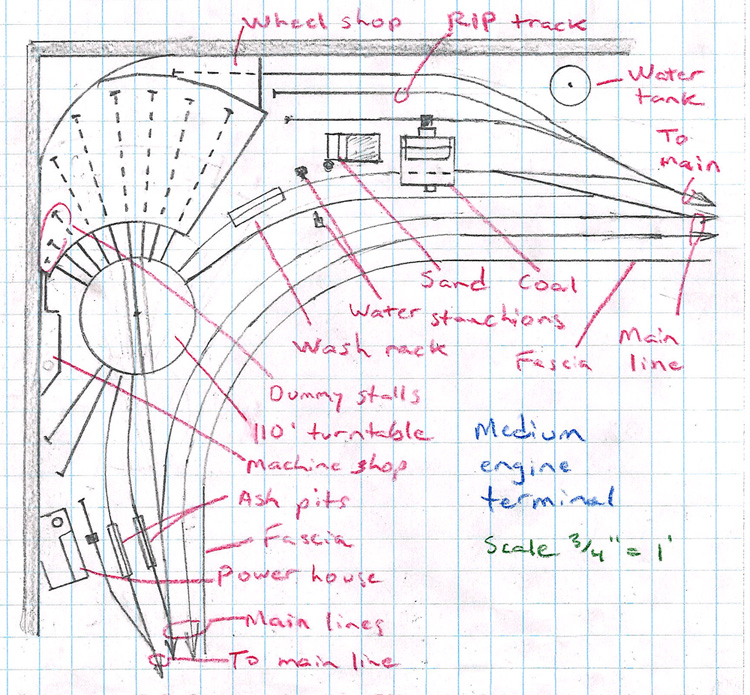

A medium steam engine terminal

This design showcases a large nine-stall roundhouse in a space often wasted on many layouts, an inside corner. A larger turntable handles more modern steam locomotives. Three approach tracks (two with ash pits) and two departure tracks keep engines moving. A powerhouse receives coal and a fascia flat gives the illusion of a machine shop without taking up much space. There’s a RIP track for light repairs and a wheel shop for truing and replacing wheels on locomotives and cars alike. (Adding a random chance of a bad order can add interest to an operating session.)

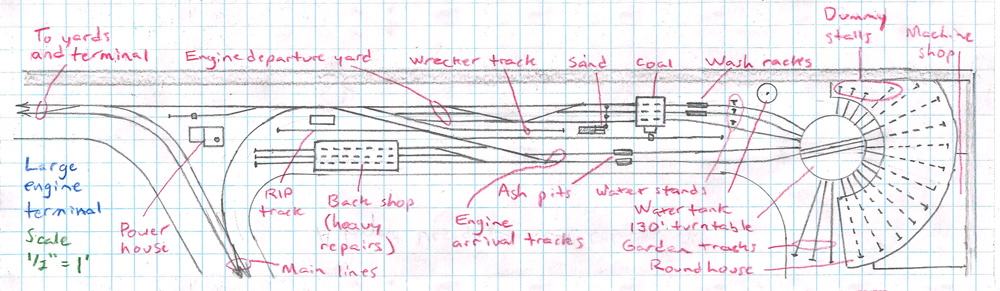

A large steam engine terminal

I had to shrink the scale on this drawing to get it to fit on the page; one square on the graph paper represents 6 inches. (Right-click the image and select “Open image in new tab” to see it at full resolution.) The shelf layout is 20 feet long, and is still selectively compressed compared to a prototypical steam engine terminal. If I had more room, I would lengthen the departure tracks and increase the size of the backshop. The 180-degree roundhouse again relies on the dummy stalls trick to make it look bigger and more impressive, but there’s enough room to store 10 Big Boys, if that’s your thing. The wrecker track is a great place to showcase visually interesting MOW equipment. In addition to providing outlets to both the main line and a nearby classification yard, the wye offers another way to turn locomotives, taking some of the burden off the turntable.

An engine terminal like this one would make a great standalone layout that could keep a trainmaster and a couple hostlers busy for hours. Just replace the yard lead and main line with a switching tail and a staging yard.

What is size of the graph paper blocks for each of the drawings?

Great info here, and I really enjoyed the article. But, I’m a diesel fan and would be really interested in the same format for diesel servicing terminals.

Same