For model railroaders choosing a separately applied roadbed for laying track, two popular options dominate: cork and foam. Each has its own strengths and weaknesses, as well as impacting factors such as ease of installation, durability, and realism. Let’s dive into the details and help you make an informed decision on cork vs. foam roadbeds.

Cork roadbed

Cork roadbed has a denser material compared to foam, which will require patience and precision when cutting to size. But once cut, shaped and glued down across your benchwork, your rail empire will rest on a solid foundation.

Pros

- Durability: Cork maintains its shape over time, resisting compression.

- Noise Reduction: The dense material helps absorb sound from running trains.

- Realistic Appearance: By splitting the cork down the middle, you get beveled edges — perfect for applying realistic ballast.

Installation Tips

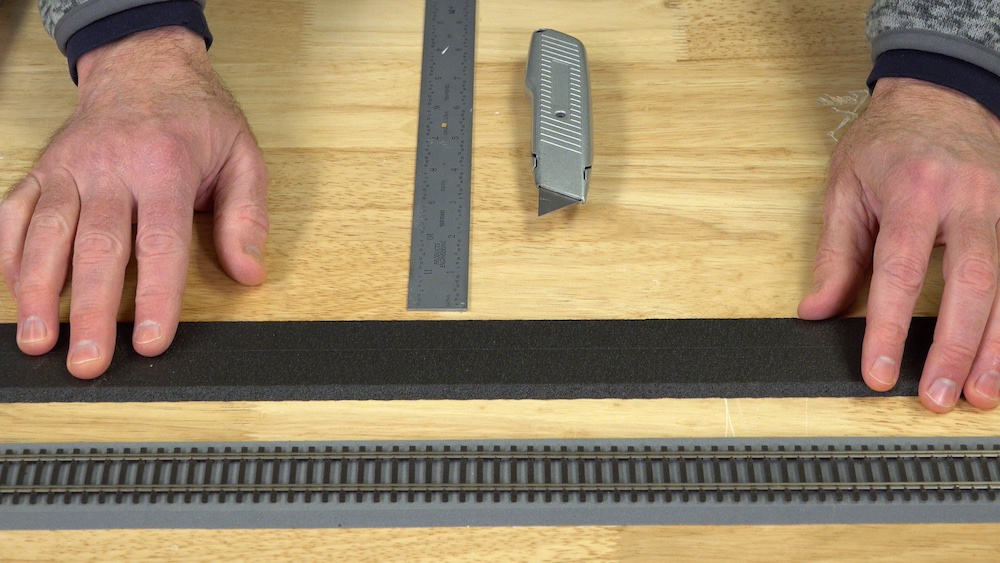

- Use a sharp utility knife and metal straight edge to cut the cork, but be prepared for multiple passes to cut through.

- Cork comes with straight edges; tearing the strip down the middle creates the desired bevel for a realistic profile. If the torn edges are jagged, you’ll need to smooth them out. The two pieces can be put back together with the beveled edges facing out.

- If the layout base is wood, wood glue is the best adhesive for securing the cork. Once settled and pressed in, the back-to-back pieces can be fully straighted out.

- Secure the roadbed with light tacks or temporary weights until the glue fully dries.

Foam roadbed

Foam roadbed is lightweight and easy to work with, making it a popular alternative to cork. Right out of the box, a single strip will come with a pre-beveled edge.

Pros

- Easy to Cut: Unlike cork, foam can be cut in a single attempt using a sharp knife.

- Flexible and Lightweight: It conforms well to curved track sections and is easy to reposition if needed.

- Pre-Beveled Edges: No extra work is required to create a realistic ballast profile.

Installation Tips

- Use acrylic latex caulk as the adhesive — it holds firmly but allows for later removal if needed. Liquid nail and PL 300 can be used as an alternative, but avoid adhesives containing solvents as they can dissolve the foam.

- Smooth out the caulk with a putty knife before placing the foam for an even surface.

- Since foam roadbed lacks a natural center guide like split cork, use a pencil line to center and align it properly.

- A paint roller can help flatten the foam and ensure good adhesion.

Which Roadbed is Right for You?

The choice between cork and foam roadbeds depends on your layout’s specific needs:

- If you prefer durability and sound absorption, cork is the better choice.

- If you want easy installation and flexibility, foam is the way to go.

Regardless of your choice, both options provide a solid foundation for your model railroad. With the right tools and techniques, you can achieve a professional and realistic track setup.

Members can watch a demonstration on how to determine cork and foam roadbeds on Trains.com Video!

I have used cork for nearly my entire modeling career – spanning some 53 years, with a couple of interludes into foam, Homasote, Celotex and other roadbed media, Homasote being the only other roadbed I would seriously consider, and even then only for hand laying/spiking ties and track. Further, I have rarely glued any roadbed. I’ve used track nails for most of my life, though in the last 10 years, I’ve been using an 18 gauge air nailer with GREAT success. What limited experience I’ve had with gluing, I doubt I would ever go back to it; it is simply too difficult to modify once the glue has set. Spiked/nailed cork roadbed is easily taken up and modified as time goes on. I have some modules which were built using cork back in the 80s and they still operate with very few issues.

IMO, of course.

I don’t use cork or foam roadbed. Cork has a tendency to dry-out and eventually crumble. It doesn’t hold spikes well, and transfers too much sound to the subroadbed and benchwork. Foam has too much give to it when a heavy car or engine passes over it. Some foam roadbed products actually transfers too much sound to the subroadbed and benchwork. This makes your layout one huege amplifier and acts like drum. I use precut homasote roadbed like the kind Central & Western HomaRoad Supply sell.

And, if you really want a quiet layout, put 1/2″ homasote below your homasote roadbed. All you hear then is the clickity-clack of the wheels running over the breaks in the rails.

Cork, at least, can take spikes to micromanage glued track, especially at rail gaps. Don’t think even the dense Walthers foam can do that. As a handlayer of track, I still use Homasote as roadbed, Very quiet, though does require a lot of cutting.