Two interesting freelanced HO flatcar and gondola loads can be made out of plastic parts from used Bic disposable razors. The flatcar load is made from the blade covers while the gondola carries cut-down handles. Of course, you need to be careful with the spent razor blades and dispose of the remnants properly to avoid injury.

The first load, representing heavy bulldozer frame castings, is made from blade covers. These parts are shipped on the flatcar with a wooden crate full of mounting brackets and fasteners. I scraped the blade covers to remove any flash and drilled small holes in both ends to add interest and remove the friction indents.

After washing the parts, I spray painted them with Floquil TTX Yellow [This paint has been discontinued by the manufacturer. –Ed.] and added 1/64″ chart tape banding. A small drop of silver paint represents the banding clamp. I used temporary tie downs made of Detail Associates no. 2210 chain (40 links per inch) to represent an in-plant load being shifted between departments, but additional bracing is required to meet Association of American Railroads requirements.

I used scale lumber for the spacers and crate. Then I added “Caterpillar” signs I made on my home computer. You could also cut similar signs or trademarks from a magazine advertisement.

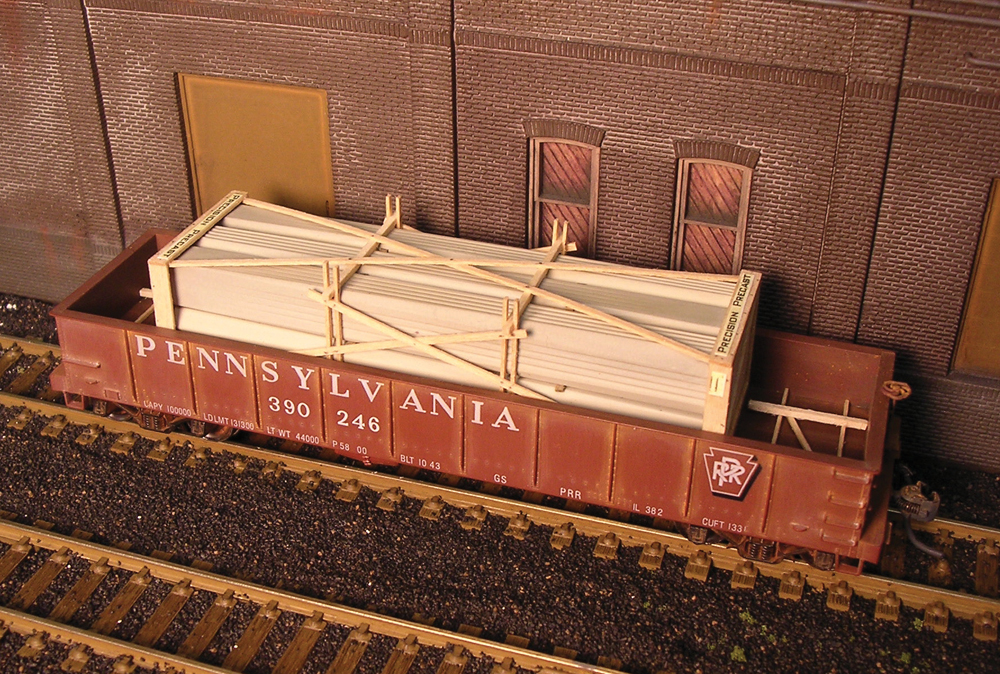

My gondola load represents concrete columns being shipped from one of my on-line industries. Made from six razor handles, they represent structural concrete columns with some architectural details, including beveled corners, fluted sides, and a taper from top to bottom. I sprayed the handles with Floquil Concrete before final assembly. Once again, I used scale lumber to make the bracing that keeps the load from shifting inside the gondola.