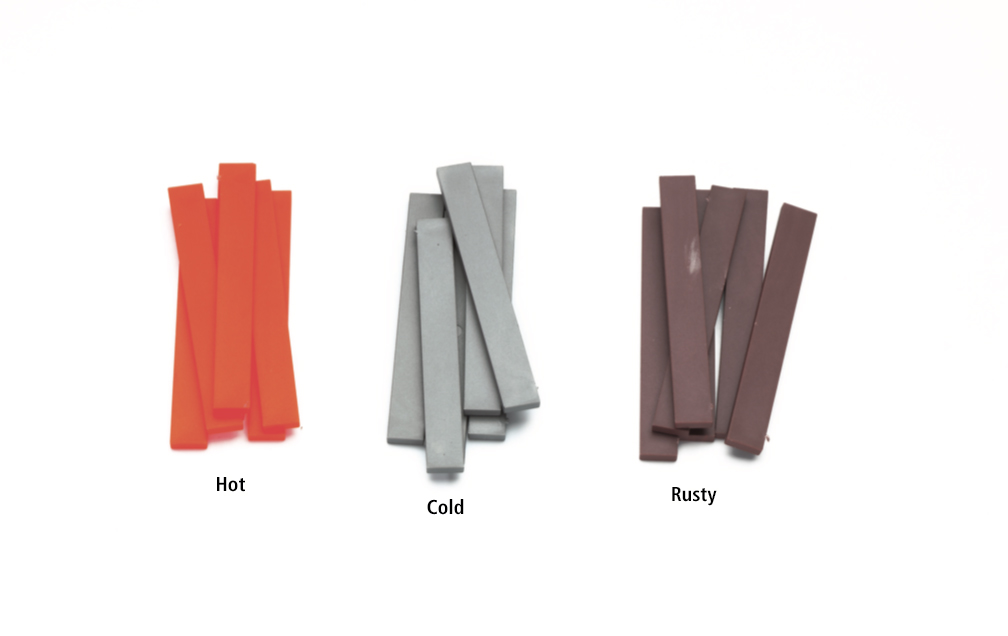

Steel slab loads have been the subject of many reader questions, including some looking for ways to simulate hot-steel loads. While it’s easy enough to cut and paint pieces of plastic to represent the cold slabs, the trick has always been simulating the hot metal.

The folks at State Tool & Die Co.have made this project really easy by releasing molded “steel slabs” in three different colors of plastic. One of these colors is a translucent red-orange that simulates the glowing color of hot slabs.

The slabs are sold in 10-packs, so I had to figure out how many to use for a load. In HO scale each slab is about 3 feet wide, 26 feet long, and a foot thick. Steel weighs just under 500 pounds per cubic foot, so rough calculations (3 x 26 x 500) indicated these slabs weigh approximately 39,000 pounds or 19 1/2 tons each.

The slabs are sold in 10-packs, so I had to figure out how many to use for a load. In HO scale each slab is about 3 feet wide, 26 feet long, and a foot thick. Steel weighs just under 500 pounds per cubic foot, so rough calculations (3 x 26 x 500) indicated these slabs weigh approximately 39,000 pounds or 19 1/2 tons each.

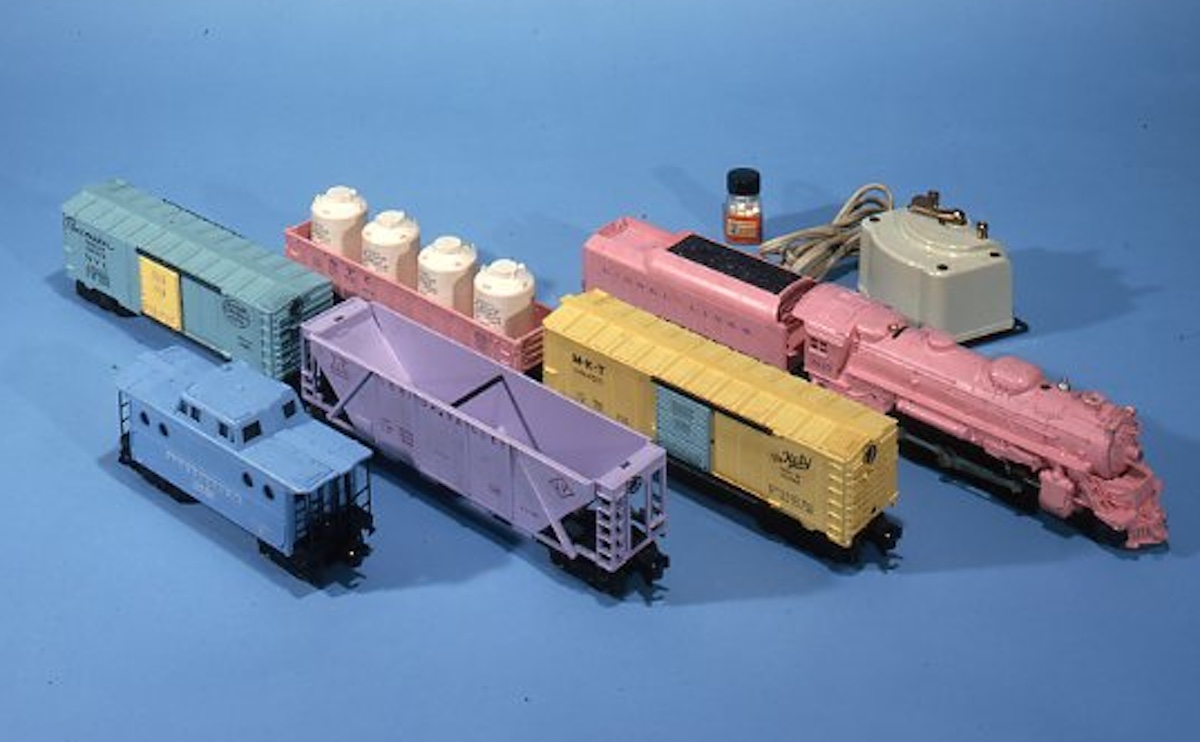

With this in mind, I decided to use six slabs on the 120-ton hot-slab car in the photo. This specialized mill car was built from a State Tool & Die Co. kit.

I used cyanoacrylate adhesive (CA) to glue the slabs into stacks of three. Loading cranes stack slabs evenly on the sides, with a space down the middle, but the ends are usually slightly uneven. A light dusting of grimy black looks like the mill scale that forms on real slabs and tones down the bright orange so the load looks truly HOT!

The gray and rusty-brown slabs are for loads in regular gondolas. At 20 tons each, a 50-ton car can carry only two slabs laid side by side in the middle of the floor. A modern 100-ton gondola would probably haul four slabs laid side-by-side in pairs over the trucks. Two or three hardwood 6 x 6 spacers are laid across the car floor, and the slabs are simply set on top. No additional bracing is necessary. These spacers are provided so cable loops can be slipped under the slabs to unload them.