Q: How exactly do switch heaters work? And how can I model a switch heater? – Bob Kolankoski

A: Over the years, railroads have tried many different methods to keep switch points from getting clogged with ice and compacted snow. One of the earliest was placing burning smudge pots between the rails. Later, more permanent switch heaters were invented. One simple type was gas pipes routed to the outside of the rails and ignited, creating the spectacular sight of flames licking up alongside the track. You could model a switch heater like this fairly easily by bending and soldering together brass wire to represent the branching gas pipes. This method is still used in areas like yard throats, where tracks are too close together for the trackside hot-air switch heaters that are more common in remote locations.

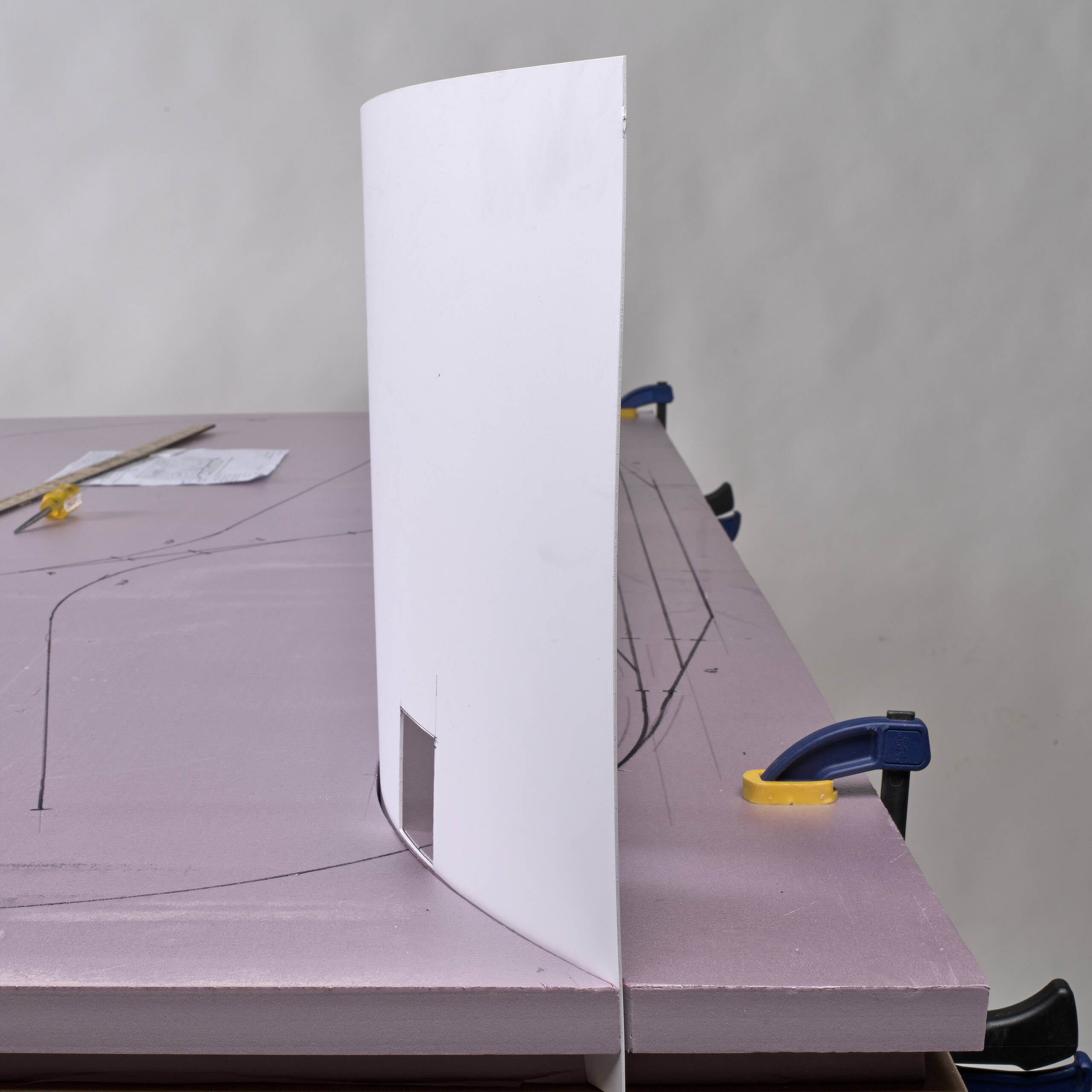

Hot-air switch heaters use a gas burner or electric heating element to heat air that is then forced through ductwork under and between the rails to melt snow and ice. This distinctive piece of equipment is often accompanied by a trackside propane tank that supplies the fuel for the burner. Frequent Model Railroader contributor M.R. Snell wrote an article for our June 2021 issue about modeling this more modern kind of switch heater. Custom Finishing Models makes the cast-metal kit M.R. Snell used in his HO scale version (part No. 283). Another cast-metal hot-air switch heater kit is offered by Details West (part No. SH-924). If you don’t want to go that route, a trackside switch heater and its accompanying ductwork is typically blocky enough to be modeled easily in styrene strip and sheet.

Electric switch heaters are even easier to model. Do an online image search for “railroad switch heater” and you’ll see, among the pictures of the two kinds I’ve described, electric heaters. These resemble wires secured by clips to the outside web of the rail. You could model a switch heater like this with brass wire, though in most modeling scales, it wouldn’t be visible. A trackside cabinet for electrical equipment would help to identify the heater’s location. If you model a snowscape, an area of dark (wet) ties and rail visible through a rectangular patch clear of snow would let the viewer know what was going on.

Send us your questions

Have a question about modeling, operation, or prototype railroads? Send it to us at AskTrains@Trains.com. Be sure to put “Ask MR” in the subject.