Q: How can N scale code 80 nickel-silver track that’s already in place and anchored to a layout be cut for block separation? What are the pros and cons of any methods suggested? The track is a combination of Bachmann EZ Track, Kato Unitrack, Atlas sectional and flextrack, and Peco sectional and flextrack. – Pete Testa

A: Flextrack that’s already fixed to a layout has to be cut very carefully to avoid pulling the rails out of the delicate plastic spike heads that hold it to the ties. With N scale, that’s even more important. Don’t use your rail nippers here; they’ll leave a pointed end on one side of the cut and might displace the rails enough to cause them to pop out of gauge. I wouldn’t recommend using a cutting disk in a motor tool either. Since the body of the tool is wider than the cutting disk, it’s impossible to cut the rails straight up and down. Plus, it’s easy for the tool to jump off course and cut more than you wanted. Instead, use a fine-toothed razor saw.

Choose a place for your gap where the track is straight, if possible. On a curve, the cut ends might try to straighten out, causing a kink. Hold the rails down firmly; you might even consider adding rail spikes on either side of the gap for a more permanent reinforcement. Draw the blade across the rails lightly and smoothly, letting the teeth do the work. You don’t want the teeth to snag the rails and “roll” them out of the spike heads.

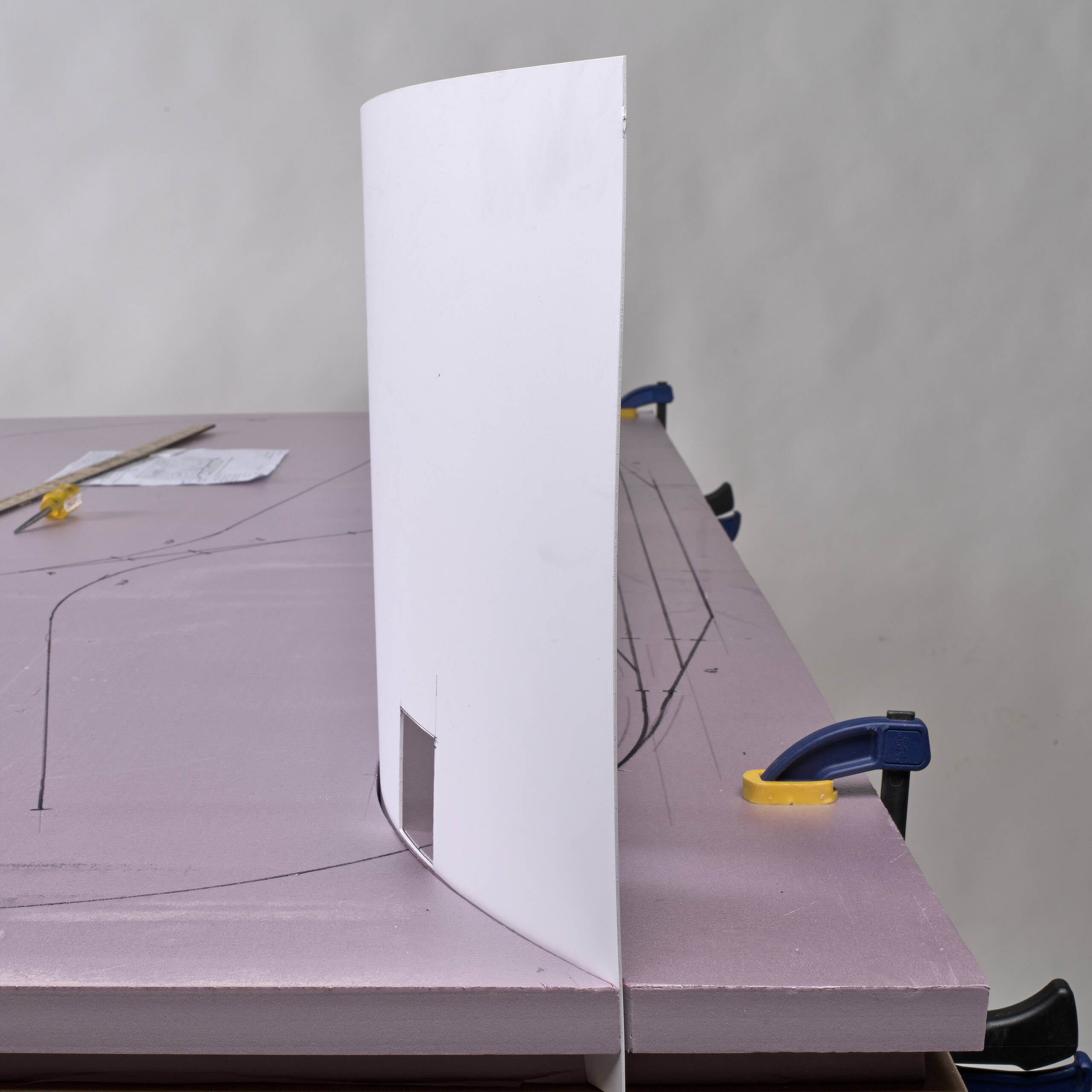

Once you’ve made your gap, cut a small square of styrene to fit the gap and use cyanoacrylate adhesive to glue it in place. After the glue is cured, use a hobby knife, jeweler’s files, and sanding sticks to trim the styrene to match the profile of the rail. Now you’ve got an electrical gap, but solid rails, guaranteeing your rolling stock will cross the gap smoothly and safely.

Send us your questions

Got a question about modeling, operation, or prototype railroading? E-mail it to us at AskTrains@Trains.com. Include your full name and hometown and put “Ask MR” in the subject.