Train Control Systems

845 Blooming Glen Road

Blooming Glen PA 18911

Website: www.tcsdcc.com

Price: $199.95

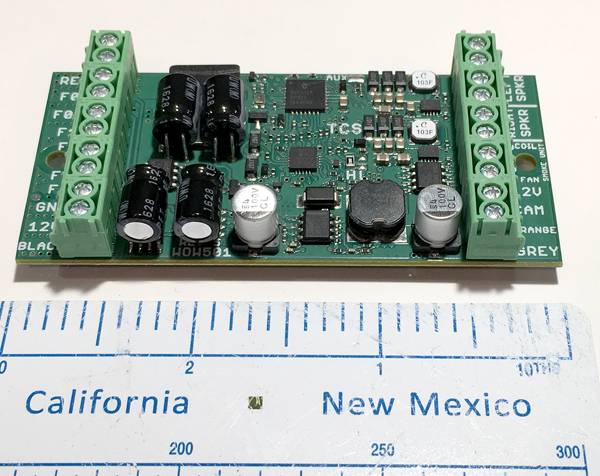

Five-amp capacity DCC motor/sound decoder; available for steam and diesel. Size: 3″ x 17/16″ x 9/16″

Pros: Good motor control; high-quality sound reproduction; many sound options programmed onto the decoder; prototypical braking; “Audio Assist” programming allows simple motor and sound programming; built-in “keep alive” allows for operation over dirty track

Cons: Prototype-mode sound response can be finicky to set up; decoder required power cycle for some CV changes to take effect (or use service-mode programming); occasional hard transition between prime mover sound samples on some sound sets.

The technical stuff. The board has a rated capacity of five amps continuous (10 amps peak), with built-in thermal overload protection. It has eight lighting/function outputs. Two of these are for the headlight and reverse light, while two can be used to run a fan-driven smoke unit (one function for the smoke-unit coil, the other for the fan). The lighting outputs can be programmed to 19 different lighting effects, including strobes, rotary beacons, and Mars lights. There are two separate speaker outputs, each driven by its own audio amplifier. An auxiliary trigger can be used to actuate one sound via a track magnet. Two rows of screw terminals connect everything to the board, except the auxiliary sound trigger, which has a solder pad on the board.

This board is designed to be run differently than you might be used to. Most of us are used to turning a knob on our throttle one way to make the train go faster, the other to slow it down. While this board supports that mode of control (called “traditional throttle mode”), that’s not how it’s intended to operate. This board is designed from the ground up to coordinate the sounds with what the motor is doing. TCS calls this “prototype throttle mode.”

For starters, there’s a good deal of momentum programmed into the throttle so, as you advance the throttle in your hand, the locomotive is slow to get moving (prototypical). As you move the knob to slower speeds or to stop, the locomotive keeps on going, slowing very gradually (again, prototypical). You don’t stop your car by letting up off the gas, you need to use the brake. On the Wow boards, the brake is the “F7” key. When you press it, the decoder applies the brakes, slowing the locomotive gradually. Press it again and the loco slows a little quicker. There are five levels of braking; the fifth press of the F7 key stops the locomotive fairly rapidly, so if you need to stop now!, pressing the F7 key five times will bring the loco to a stop within a few seconds. It’s not immediate, to save damaging gears.

This takes some getting used to. It’s not instinctive to anyone used to “knob-up, knob-down” train control. However, some form of prototypical braking functionality is becoming more prevalent in command-control systems. Of all the versions of this technology I’ve tried, I like TCS’s five step, progressive braking the best. That “just a little bit, now a little bit more” approach is quite realistic. The braking feature works no matter where the throttle is set—you can be running full speed, hit F7, and the loco will come to a stop. Releasing the brakes (F6) will start the loco moving again back to its original speed. Turning the throttle up will also release the brakes.

Sound. The prime-mover (diesel motor) sound is integrated into the throttle setting. The idea is that you calibrate the locomotive using “Audio Assist” (more on that in a bit), with it running light, then pulling a heavy load. The decoder reads the motor’s back electro-motive force (BEMF), and uses variations in that to control the sound as the loco pulls the train around the railroad. If the locomotive encounters a grade, you may hear the prime movers “notch up” in response to the change in grade, giving the sound of a locomotive working hard. Conversely, if the loco starts downhill, you may hear the prime movers drop down a notch or two, as the loco does not need to work as hard. You can customize the amount of change and its sensitivity to load changes but the decoder also takes into account how fast the locomotive is traveling and adjusts its responses accordingly. For instance, I can run my locomotive around the railroad at fairly low speeds, and even minor changes in grade or load register with changes in the sound of the prime mover. As I run faster, it takes more of a change in load to get the prime mover to notch up, simulating the effects of momentum of a heavier train at higher speeds, where the force of the train pushes the locomotive up the hill, requiring a little less work by the loco.

Because all of this is based on the locomotive’s BEMF, the settings will be unique to each locomotive and may take some fiddling to set up. In addition to the board’s auto-calibration for load, you can customize the sensitivity to those changes, how much the prime mover changes in response, and other parameters. This is finicky and the manual isn’t as clear as it could be. A little patience (and maybe an e-mail to TCS for help) will get you through this. It is pretty cool to hear the locomotive encounter a grade and hear the prime mover notch up as the train works its way up. The steam software has a similar feature regarding chuff. The harder the loco is working, the louder the chuff. If it’s drifting downhill, all you hear is the quiet clanking of the rods.

The diesel board also offers simulated working dynamic brakes. When you press the dynamic brake button (F5) once, you hear the prime mover drop to notch 3, and the dynamic-brake fans kick in, but the loco’s speed stays the same. A second press begins to slow the loco at a pre-programmed rate and kicks the prime mover up one notch. The F6 key releases the dynamic brakes.

Overall, the motor control and the sound response is quite good. Although it was finicky to set up, once it’s dialed in and tuned to your locomotive, it’s a blast to watch (and hear) run. The motor control itself is smooth, though I did notice the occasional stutter at very low speeds. This is not objectionable and really only manifests itself when cruising at those low speeds. In normal operations, one rarely runs at speed-step 1 for a length of time.

For those wanting a more traditional approach to running, you can change the operational mode to “Traditional throttle mode,” and you’ll have direct control of the locomotive. The faster the locomotive runs, the faster the sound of the prime mover. There’s no load-sensitive aspect to the prime-mover sounds.

One thing TCS did with this board was to create two modes for the function keys: “light mode” and “sound mode.” You select between the two with the F8 key. A voice announces which mode you’re in. (You can turn this off.) The advantage is that you have 28 function keys available for lights and an additional 28 keys available for sounds. Whether that’s really needed (with only six controllable lighting functions) I don’t know, but older controllers may not go up to 28 functions, so it has its advantages. You can also combine light and sound functions so that, for instance, when you blow the grade crossing, the ditch lights flash. I seldom have need to be turning lots of lights on and off in the course of an operating session, so I usually just enter “light mode” when I power the loco up to set the lights I want on, then go to “sound mode” for the duration of the operating session.

The sounds available on this board are extensive. There are nine prime movers: three Alcos, three EMDs, and three GEs. All sound good. The diesel board offers the user 33 different horns and 49 different bells. You can select these sounds “on the fly” using the F9 key—what they call “rotate whistle.” If you’re running and decide you’re tired of the horn sound, just hit F9 to select a new one. If you turn the bell on, then hit F9, you can select a bell the same way. The direction indicated on the controller determines which way you scroll through the list of available sounds. Each whistle has three options: a long, a short, and what TCS calls a “quillable whistle.” This is usually a recording of a grade crossing whistle, but some are a bit more stylized. Many whistles have two or three quillable whistles associated with them. Each press of the grade-crossing button runs through the next available sample. I like the variety—you can tell the engineers had fun “playing” the whistles/horns for these recordings. The only snag is that I don’t know which one I’m going to get—the samples are of varying lengths and it’s hard to figure out just how far in advance of the grade crossing I need to press the button so that the recording finishes when I get to the crossing.

In addition to using a function button to select your whistles, TCS has introduced a similarly unique way to program many of the parameters of this decoder. They call it “Audio Assist.” Think of it as an automated telephone system. Press 1 for sound options, press 2 for light options, etc. TCS offers a flowchart in the manual to help. With Audio Assist, you can select sounds, adjust their volumes, map certain sounds to particular function keys, program lighting functions, speed-match your locomotives for use in consists, and calibrate your motor for BEMF control. I’ve programmed a TCS decoder (not this one) without needing to program a single CV via conventional DCC programming. Everything was done with Audio Assist.

The parameters that you will need to delve into CV programming include the BEMF adjustments I mentioned above, braking and acceleration rates, decoder address, and similar. I did notice that, on this specific board, I had to program the CVs I programmed in “service mode” to get the changes to take immediate effect. If I used “programming mode,” I’d have to cycle the power to the board to see/hear the changes. This is different from my other TCS decoders, so it could be a quirky thing with my specific board. Not a huge deal, but certainly a curiosity.

Both steam and diesel sounds are clean recordings. The five-amp board has two speaker outputs but the board is not a “stereo” board. There’s no way (currently) to adjust the individual sounds so that they favor one speaker over the other. As it is, it’s nice to be able to have two separate outputs so I can use two eight-ohm speakers without worrying about overloading the audio amps. I put two speakers in my test loco and the sound is great. Full volume is far louder than what I usually run in my back yard.

I’m pleased with this board. It’s a good choice for a modeler who’s a novice at DCC and is confused by CVs and the like. The Audio Assist makes it a great way to get your feet wet and customize your board without over-complex programming. For the modeler who’s used to DCC, you can customize cool things by reading the manual and learning your way around TCS’s 4-CV indexed programming. I often joke that the only reason I have diesels on my railroad is that the modern sound decoders make them operate so realistically that you can’t help but enjoy running them. I definitely enjoyed running this one.

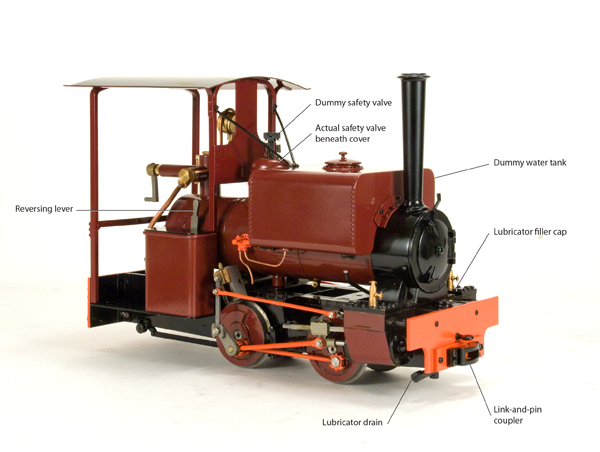

The decoder was installed in an LGB White Pass diesel in this particular example. It would work equally well in any large scale diesel. The decoder has multiple prime mover sounds (motors), so you can easily pick the prime mover that’s prototypical for the loco into which you’re installing it (or whichever one sounds best to your ears if that works better for you).

With regard to control, the decoder is DCC, so works on any NMRA-compliant DCC signal. That signal can come from either a traditional track-based DCC command station (NCE, Digitrax, MRC, etc.) or on-board (battery) wireless receiver such as Airwire’s “Convertr” or Tam Valley Depot’s “DRS1 Hi-Power.” In this particular installation, I’m using a Tam Valley Depot receiver to feed the signals to the decoder, though I also tested it with a traditional track-based command station (MRC’s Prodigy Advance), and also programmed the decoder with JMRI (Java Model Railroad Interface) on my PC.

I feel some important details were left out. What type of locomotive was this installed in? What was used to control it? Track power, or battery?