Let me introduce you to a new online-only feature of Garden Railways magazine. I am going to discuss the latest in available modeling technology and the potential impact it may have on our hobby. I am going to feature technology overviews, resources, links, projects, and question and answers. I invite all hobbyists to join the conversation. Tell us how, in your experience, technology has impacted the hobby, what would you like to see discussed, and ask questions. I plan to cover everything, from 3-D printers and laser cutters, to more advanced subjects, like the latest in software, while offering some suggestions on where to use it.

Please post your comments and questions in our forum thread.

Introduction to 3D printers and how to get printing quickly

As with any tool, you must first understand the features and limitations of the tool to use it effectively. I hope to give you the information necessary to better understand the 3D printer, its general processes, and what is possible with this technology. I will leave you with a quick-and-easy example of its capability.

Basic printing method

3D printing is a generic term that generally refers to any process used to make three-dimensional objects via what is called, “an additive process.” There are many different additive processes but I am only going to discuss the most common, consumer-related printing technology, which is referred to as Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). The part is produced by extruding thin strings of material to form layers that match the shape of the part to be produced.

Plastic is fed through a heated extrusion nozzle, where the material becomes pliable. This is called the “glass transition temperature.” A worm drive pushes the molten plastic through the nozzle at a computer-controlled rate. The nozzle assembly can move in the X-Y-Z axes. This is also computer controlled. The nozzle moves in the X-Y (two-dimensional) direction first, laying down a thin layer of plastic. Once a layer is completed, the computer will move the nozzle assembly in the Z (up-down) direction and the next layer of material is deposited. This is repeated until the part is complete.

Printing material

There are several different polymers that can be used for 3D printing. Each has specific properties that are important to know before you begin to print your part. The most common materials used by consumers are polyactic acid (PLA) and acylonitrile butadience styrene (ABS). Don’t let the fancy names intimidate you. PLA is basically processed corn starch and ABS is derived from natural gas and petroleum.

ABS is used for its toughness, impact resistance, and gloss. It will, over time, deteriorate with exposure to sunlight. Printing with ABS must be done in a well-ventilated room. The fumes have known low levels of carcinogens; thus, exposure to them should be minimized.

PLA is less tough, has low impact resistance, and is especially susceptible to water and sunlight. Its fumes are not toxic and actually smell pleasant.

Printers

There are many different types and designs of 3D printers available. Some are elaborate and complex, while others are simple and elegant. The price of printers are reaching consumer levels, with some starting as low as $400 and up. More expensive printers have additional features that cause the cost to rise. Even the most basic printer can produce good results if the operator is experienced and knowledgeable.

I will be covering some of the most popular printers at a later date, but here are a couple of things that you should look for: a heated print plate is needed for printing ABS, not PLA. Dual extruders are necessary only if you want to print two colors at the same time or if you don’t want to keep changing the filament out for different parts.

Getting Started

The easiest way to get going is to check out many of the free or fee-based designs that exist on the internet. Here are some websites that you might want to check out:

http://www.hongkiat.com/blog/download-free-stl-3d-models/

https://all3dp.com/best-sites-free-stl-files-3d-printing/

You could also do a search to find more sites. In general, what you are looking for are *.stl files, which stands for Stereo Lithography. You can go to your favorite web site that offers 3D models (my favorite is www.thingiverse.com) and download the *.stl file of your choice. You can then view this file by using a free, downloadable *.stl viewer, such as www.freestlview.com or www.viewstl.com; the latter is the one that I use.

To get the part printed, there are several resources. One of the most popular is www.3dhubs.com. This website serves as a clearing house for all the local 3D printers in your area. Enter your ZIP code and you will be able to find a list of available printer resources, get a quote, pay for the part, and, in a couple of days, receive your printed part.

You will be asked several questions. The first concerns your desired material. I always use ABS, but nylon, PLA, and other materials might also be available. Next is the size of the finished part. Your *.stl file might be a different size than what you want. Give them the approximate size of the object that you want printed and they should be able to get close. Finally, they will want to know the resolution of the printed part, typically low, standard, or high.

Example

Let’s make a brake wheel. Go to:

http://www.thingiverse.com/thing:400368/#files

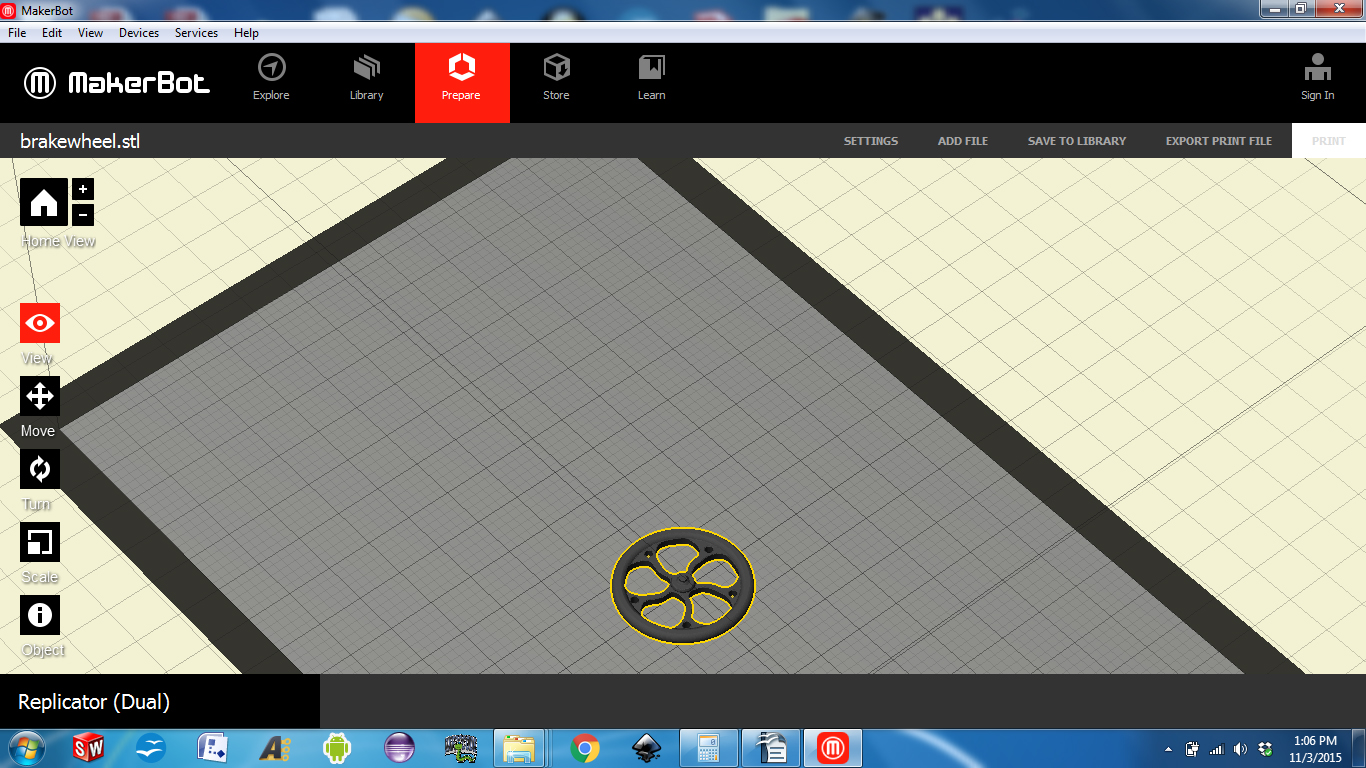

and download the file brakewheel.stl (it is the only one available at this site). Alternatively you can just go to http://www.thingiverse.com and type in the search window, “brake wheel.” You can view the file by going to www.viewstl.com, browse your computer to the location where you saved it, and take a look. See photo 1.

If this is what you want to print out, you can then go to one of the printing resources and have them print out your part. (See the Resources section for printer resources.)

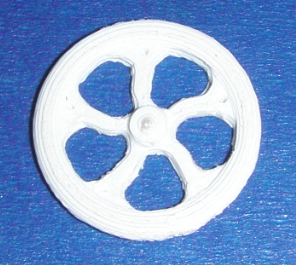

I had to do some resizing to get the part to match the scale that I wanted. Then I set up the printer characteristics and printed the file. See photo 2. As you can see, I have some work to do to clean up the flash on the part. See photo 3.

Photo 4 shows the completed part. I have cleaned up the flash, lightly sanded the wheel, painted it, and sprayed it with a protective polyurethane coating. It is now ready to go on one of my flatcars.

Resources

Here is a list of some services and software that you might want to look into. Don’t forget that you can search the Internet and find many more options than what I listed here.

Design services will take your concept and turn it into a *.stl file or print the part for you:

sberneberg@spatialapplications.com

Viewing *.stl files.

Printing resources are groups that will print the part for you if you have an *.stl file:

sberneberg@spatialapplications.com