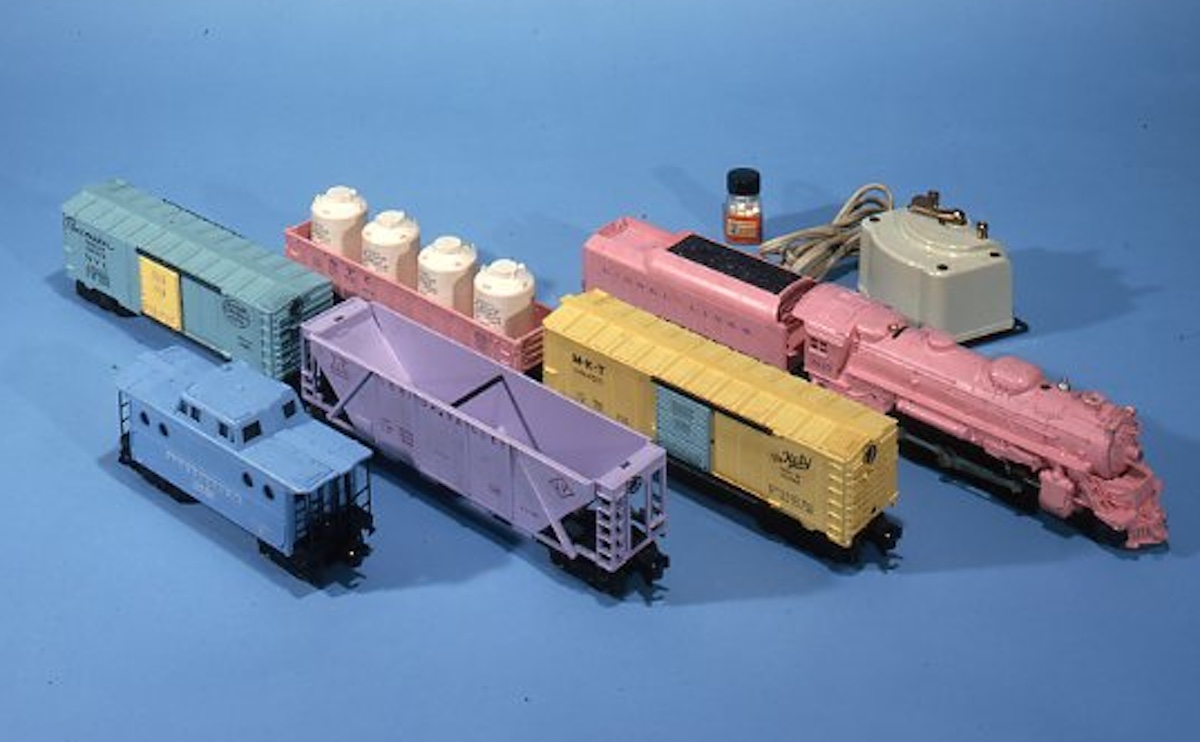

Locomotives and rolling stock are pretty durable in the O and S gauge hobby, but even the best performers in your fleet will benefit from regular inspection, cleaning, and oiling.

Here are seven of our most essential maintenance basics. Most of these tips are one-evening projects, and some take even less time. Give them a try and your toy train empire will operate better, whether it’s small or large.

1. Check coupler shanks and coupler springs

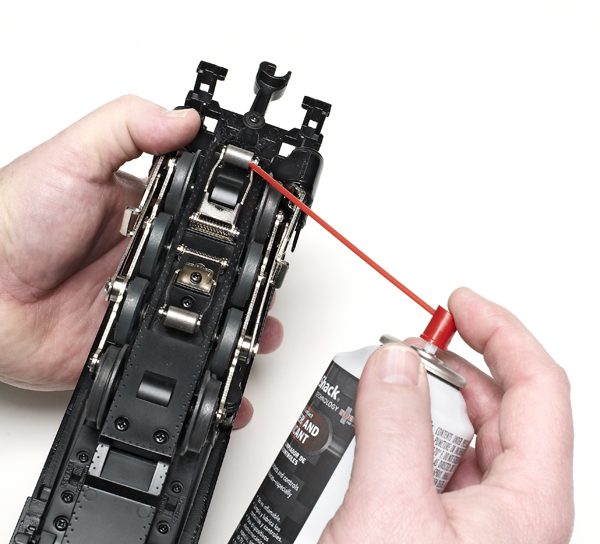

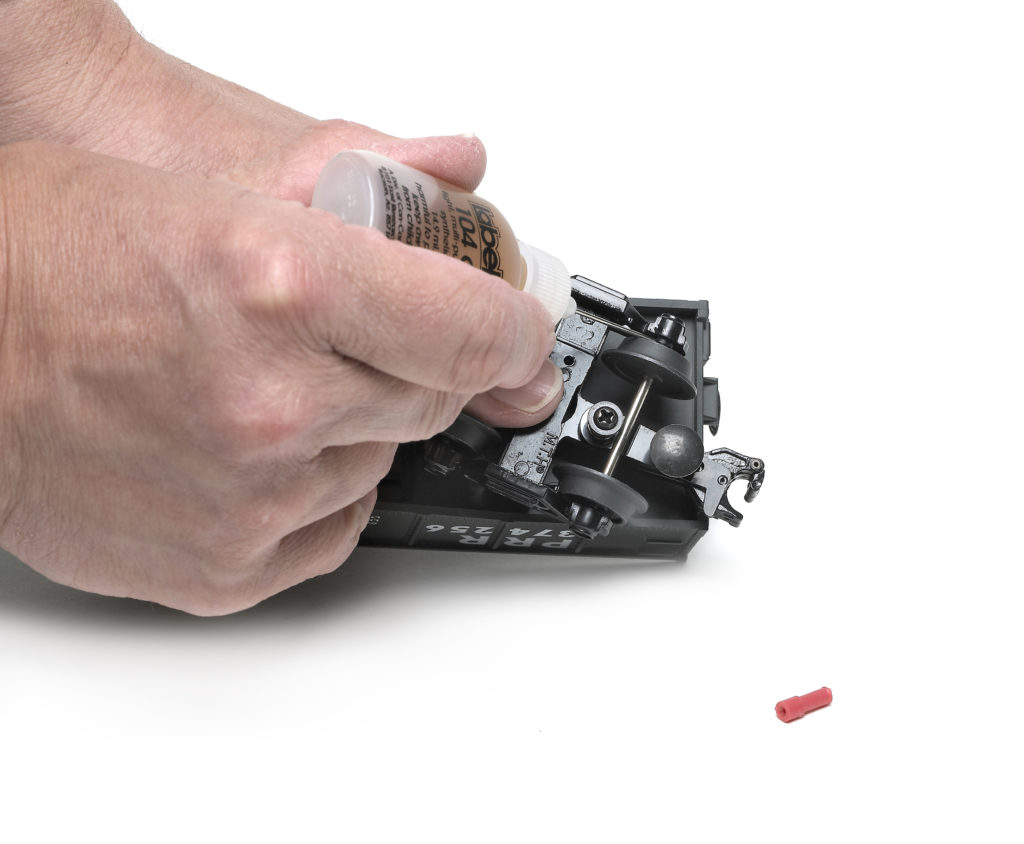

2. Lubricate and oil engine

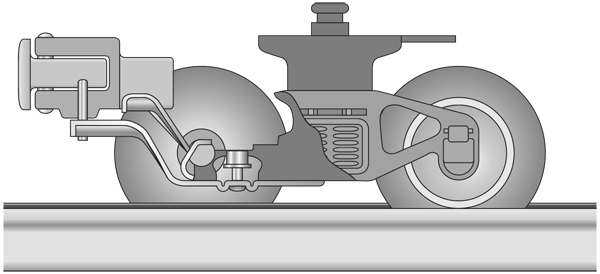

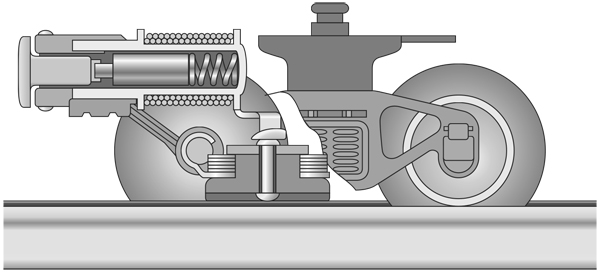

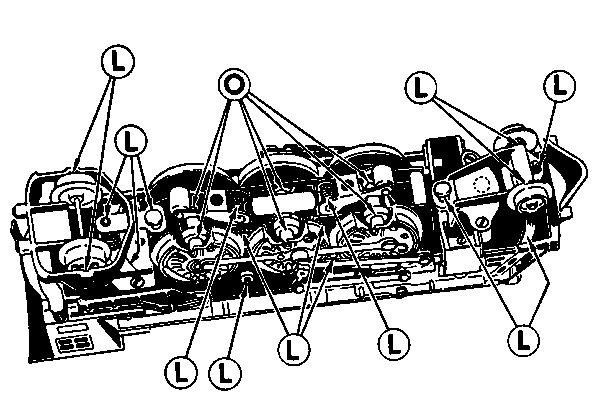

Most locomotives don’t require a lot of maintenance, just periodic cleaning and lubrication. Pay special attention to the ends of the motor armature and to the ends of the axles. Put a little grease on any exposed gears. If you have a steam locomotive, put a little oil on the side rod screws also.

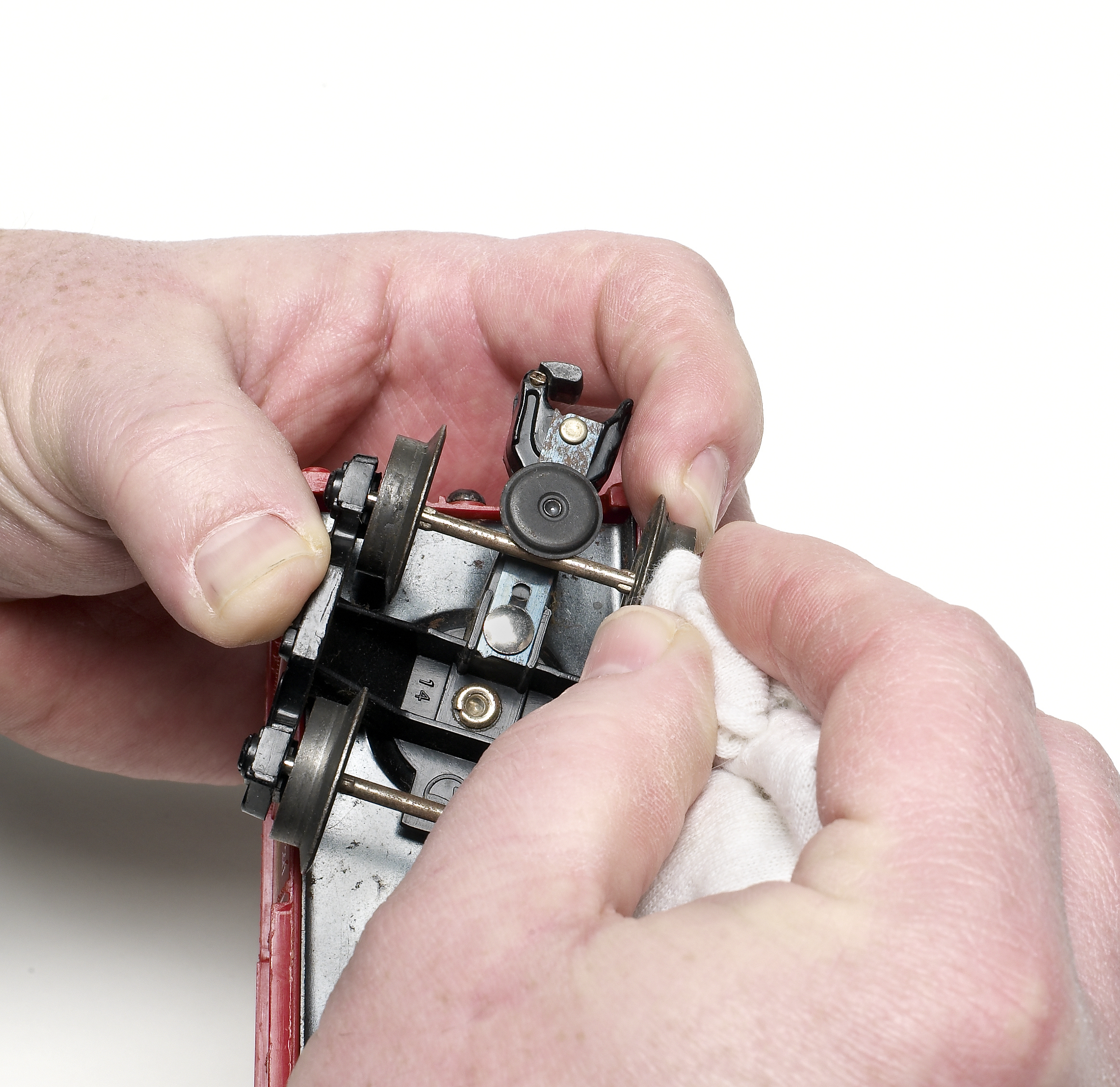

3. Check pickup rollers

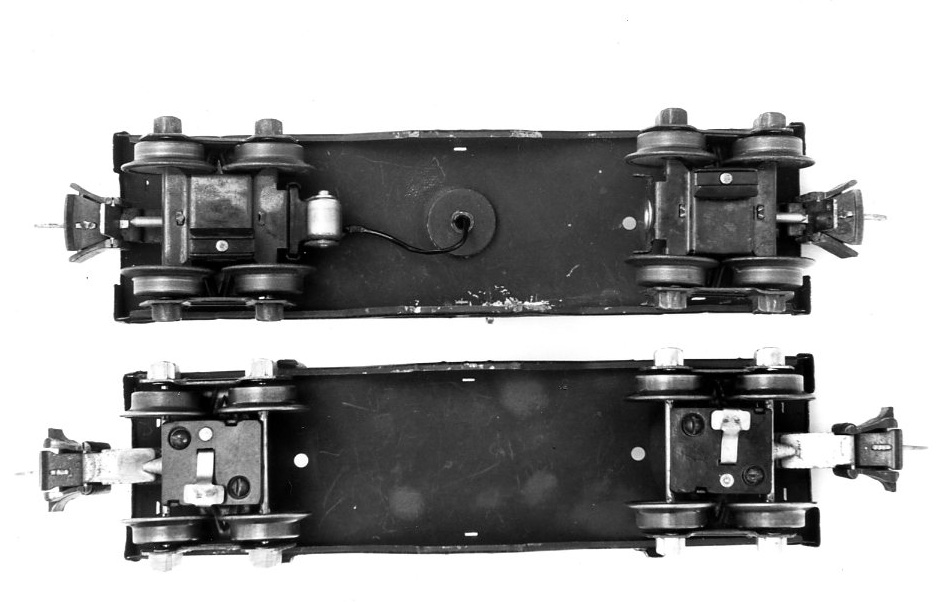

4. Check wheel gauge

Even toy train wheels can come out of gauge. If you have a car that derails frequently, especially at switches, check the gauge using a set of calipers. Look for bent axles as well, because they can also cause poor operation. An easy way to check this is to make sure all wheels are touching the rails when the car or engine is sitting on the track.

Postwar wheels rotate on a fixed axle and the wheel centers can wear over time, causing the car to wobble. These wheels can be replaced with good-condition originals. Reproduction postwar-style wheels are also available from Lionel parts dealers.

5. Oil axles

6. Clean the wheels

Art Larabee Try CRC contact cleaner, available at Grainger and other commercial outlets.

Please advise what cleaner can be used in place of the one

from Radio Shack that is no longer in business. Thanks.