Q: Are Atlas turnouts “DCC friendly” in the way Walthers turnouts are advertised? Do I need to do anything special to make Snap-Switches and other track products operate properly on a Digitrax DCC powered layout? – Edward Gardineer, East Berne, N.Y.

A: Before I answer your question, I have to give you two caveats. First, although our DCC Currents columnist Allen Gartner invented the term “DCC friendly,” neither the National Model Railroad Association nor any other body enforces an official definition. So two different manufacturers can both call their turnouts DCC-friendly even if they may be constructed and/or wired differently. Second, if it’s properly installed and maintained, and traversed by rolling stock whose wheels are in gauge, any turnout can be used on a DCC layout. Direct current is actually less tolerant of short circuits than DCC.

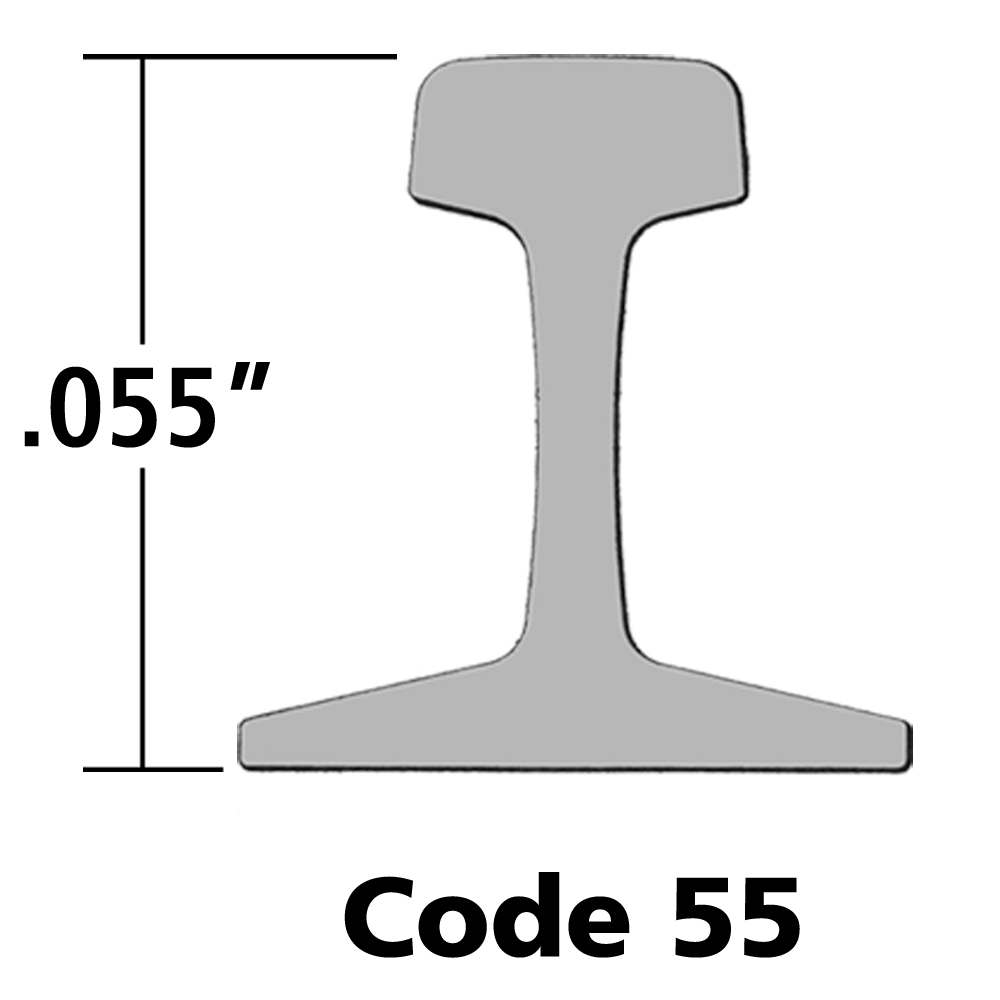

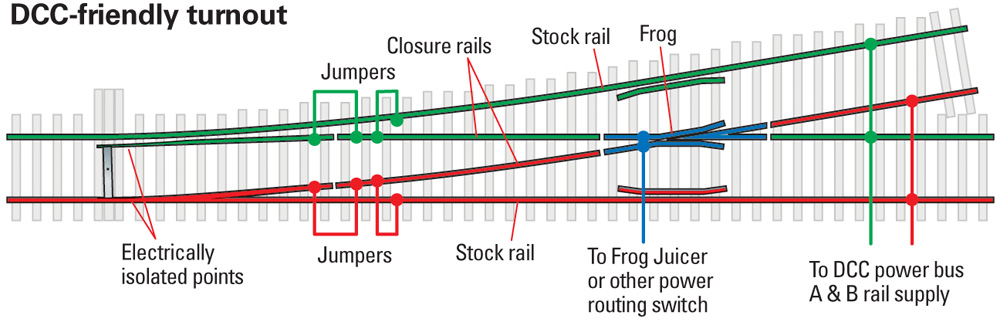

That said, Atlas has several different lines of track – code 100, code 83, Snap-Track, True-Track, etc. So the answer is “it depends,” which I recognize is less than helpful. So let’s look at what “DCC friendly” means. When a metal wheel that’s slightly out of gauge comes in contact with a point rail and a stock rail that are energized with opposite polarities, a short circuit occurs. A DCC-friendly turnout is one that minimizes the risk of that happening by electrically isolating its point rails, closure rails, and frog, powering each set of points and closure rails the same as their adjacent stock rails and switching the frog’s polarity depending on the route lined through the turnout.

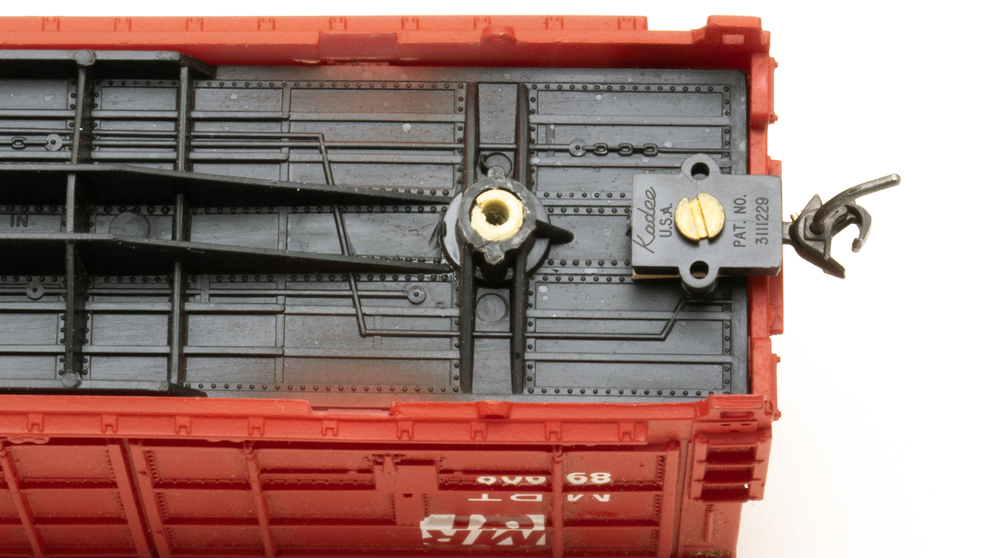

A turnout that calls itself DCC friendly should come wired like that out of the package, but if your turnouts aren’t, you can still make them so. Use a razor saw or a cutoff disk in a motor tool to separate the closure rails from the frog and install jumpers under the track connecting each point/closure rail assembly to its adjacent stock rail, as shown in the diagram above. Then attach a wire to the frog and run it to a switch that will change the polarity depending on the way the points are lined, like a Tam Valley Frog Juicer or the secondary contacts on a Tortoise by Circuitron switch motor. With some turnouts, this may be tricky, because some come with pot-metal frogs that don’t take solder well. If that’s the case, look for a little tab on the side of the frog, screw a small brass screw into the hole, and solder your wire to that.

Q: How do I convert an HO scale track plan to O scale? – John Redinger

A: It’s not exact, but HO stands for “half O scale” for a reason. Double the dimensions of the HO scale plan and you’ll have a rough equivalent in O scale. Just be on alert for issues of reach-in access, as increasing the width of the layout doesn’t increase our ability to reach in that doubled distance. You may need to pare down the number of tracks in a yard or add access hatches to reach some areas. On the bright side, doubling the size of the plan will also double the width of the aisles, so you might find it possible to split shelves and peninsulas down the middle for better access. Converting an N scale plan to HO scale works the same way.

If you’re converting in the other direction – HO to N scale, for instance – just cut the dimensions in half. But just as before, look out for aisles and accessways that are suddenly too narrow for a typical operator to enter. You may have to stretch some areas and reduce others to make sure 1:1 scale humans can fit.

Send us your questions

Do you have a question about model railroading you’d like to see answered in Ask MR? Send it to associate editor Steven Otte at AskMR@MRmag.com.