Bristling with separate detail parts, the die-cast metal HO scale Allegheny 2-6-6-6 from MTH accurately models the looks and performance of its legendary late steam-era prototype.

The model features MTH’s proprietary Digital Command System that operates on direct current, Digital Command Control, and DCS layouts.

The prototype. From 1941 to 1948 the Lima Locomotive Works delivered to the Chesapeake & Ohio Ry. 60 of the largest and most powerful steam locomotives ever built. The C&O classified the engines H-8 and nicknamed them “Alleghenies” after the mountain range where they ran. Eight near-duplicates were delivered to the Virginian Ry. where they were classified AG and known as“Blue Ridge” locomotives.

The simple articulated steam locomotives featured two steam engines with high-pressure cylinders under a single boiler. The front engine pivoted, allowing the massive locomotive to round curves. An Allegheny could produce 6,900 hp at 45 mph. On the C&O, a single class H-8 regularly hauled 140 loaded coal hoppers from Hinton, W.Va., to Clifton Forge, Va.

As diesel-electric locomotives became more prominent, all 2-6-6-6 locomotives were retired by 1956. Two C&O Alleghenies have been preserved: No. 1601 at the Henry Ford Museum in Dearborn, Mich., and no. 1604 at the Baltimore & Ohio RR Museum in Baltimore.

The model. The MTH Allegheny is within scale inches of prototype drawings in The Model Railroader Cyclopedia, Vol. 1: Steam Locomotives (Kalmbach Publishing Co.). The remote-opening coupler on the tender is oversize, so it makes the overall length of the tender a scale foot too long. For those who want a more in-scale appearance, a user-installed Kadee no. 58 scale magnetic knuckle coupler is included.

The die-cast metal locomotive and tender features sharply defined cast-in detail including rivet seams and boiler bands. The model is accurately detailed for C&O numbers 1600 to 1644, including 8-pane cab windows, curved bell bracket, non-slotted eccentric cranks, and straight cab side ladders.

The handrails, whistle, and bell are separately applied metal parts. Other separately applied details include the coal load in the tender.

The cab interior features a detailed backhead with painted gauges and valves. Painted engineer and fireman figures are also included.

The locomotive and tender lettering is the correct font. Its placement also matches prototype photos.

The mechanism. The five-pole skew- wound motor is housed inside the die-cast metal boiler. Gearboxes connect the motor to the second axle of the front engine and the third axle of the rear engine. The drivers on the third axle also feature plastic traction tires. The metal siderods transfer power to the other axles.

On a prototype articulated steam locomotive, the front engine pivots around curves, while the rear engine is fixed. On the MTH model, both engines pivot. This, as well as an extra scale foot between the locomotive and tender, are necessary to allow the model to negotiate tight 22″ radius curves. The locomotive drawbar allows for closer coupling, but this requires wider-radius curves.

The traction tires and heft of the locomotive give the MTH Allegheny exceptional tractive effort that’s equal to 134 free-rolling HO freight cars on straight and level track. During mountain climbing tests I used the Allegheny to pull 40 cars up a 3 percent grade.

The DCS printed-circuit board and speaker are inside the tender. I appreciated the user-friendly drawbar connection. Metal electrical conductors inside the drawbar eliminate the need for a separate wiring harness.

Master sound volume and smoke knobs are located under the water hatch atop the tender. A Phillips-head screwdriver is required to adjust each one. When using the model with a DCC or DCS system, both the sound and smoke volume can also be controlled with function keys.

The remote-opening coupler on the rear of the tender is mounted .03″ too high according to a Kadee coupler height gauge. The centering spring is also a bit stiff. I had to use an uncoupling pick to center the coupler during operations. The knuckle is strong, and didn’t inadvertently uncouple, even during the hill climb test.

The Kadee no. 58 knuckle coupler on the pilot is at the correct height.

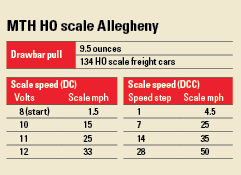

DC performance. Using a DC power pack, the locomotive crept along at 1.5 scale mph at 8 volts. The model accelerated smoothly to 33 scale mph at 12 volts, which is our standard speed test maximum, and reached a prototypical top speed of 60 scale mph at 18V. The MTH model can handle up to 24V.

Most of the sounds in DC are automatic, including the air pumps. The exhaust sound features the prototypical four chuffs per wheel revolution. When turned on, the puffing smoke unit is also synchronized to the exhaust chuffs. As the locomotive gains speed the exhaust sounds of the two engines realistically go in and out of synch.

DCC and DCS performance. On our DCC test track, the Allegheny started moving at 4.5 scale mph in speed step 1, accelerating to 50 scale mph in speed step 28. When I set the DCC system to 128 speed steps, the locomotive moved at 1 scale mph in speed step 1.

The model features 28 user-triggered functions. The whistle has a deep steamboat quality that sounds similar to prototype recordings I’ve heard. Forward,reverse, and grade-crossing whistle signals can be triggered with a single keypress. I could also trigger the bell, lights, and simulate the sound of coupler slack letting out as the locomotive got underway. Function 4 triggers a four-part dialog sequence between the train crew. Function 8 opens the knuckle on the tender’s remote-opening coupler with appropriate sound effects.

All the functions can be remapped to different keys. This is especially useful for modelers using throttles that don’t support 28 functions.

A list of all the DCC functions and programmable configuration variables (CVs) is included in the printed user manual. The MTH model can be programmed on the main or a programming track. A programming track booster may be required for some systems.

On our review sample, I programmed the model’s long address to match the locomotive number and added both acceleration and deceleration momentum. Locomotive performance can be further fine-tuned by using CV25 to select from 17 speed tables.

Using a DCS system, the MTH model accelerated at 1 scale mph increments to 50 scale mph. Along with the other functions available when using a DCC system, the DCS system let me adjust the volume levels of individual sound effects. I especially enjoyed being able to quill the whistle with the DCS throttle.

The Allegheny is available in a European version that operates on stud-rail track, such as Märklin C- or K-track.

With its exhaust barking and smoke pouring out of the stack, the MTH HO scale Allegheny looked awesome conquering the grade on our layout. It’s a worthy model of Lima’s finest.

Manufacturer

MTH Electric Trains

7020 Columbia Gateway Dr.

Columbia, MD 21046-1532

www.mthhotrains.com

Road numbers (all Chesapeake & Ohio): 1601, 1604, 1610, 1618

Era: 1941 to 1956

Features:

▪▪Die-cast metal construction

▪▪Digital Command System with Proto-Sound 3.0 operates on DC, DCC, and DCS layouts

▪▪Five-pole skew-wound motor with brass flywheel

▪▪Electrical pickup on 10 drivers and all tender wheels

▪▪Kadee no. 58 knuckle coupler on pilot (at correct height)

▪▪Light-emitting diode (LED) headlight, backup light, number boxes, and cab interior light

▪▪Metal RP-25 contour wheels in gauge

▪▪Minimum radius: 22″

▪▪Operating smoke unit

▪▪Remote-opening coupler on rear of tender (.03″ too high)

▪▪Traction tires (user installed driver without traction tires included)

▪▪28 DCC functions

▪▪Weight: 2 pounds 5.6 ounces (total); 1 pound 10 ounces (engine alone)

Appears to be a great model. I saw the 1604 in Baltimore and was struck by the size of the beast. It must have been awesome in action, both to hear and to see. I will check out the video to see if it sounds and runs as good as it looks.