Accucraft

33268 Central Ave.

Union City CA 94587

Price: $2,337.50

Website: www.accucraft.com

1:32 scale, gauge-1 model of a Southern Pacific M-6 2-6-0 standard-gauge steam locomotive; all-metal construction; gas fired, single-flue boiler; 60 psi working pressure; fittings include throttle, pressure gauge, water glass, safety valve, filler plug, check valve, bypass valve; displacement lubricator; working drain cocks; axle pump; hand pump in tender; reversing via between-the-frames eccentrics with reversing links controlled from the cab; Vanderbilt tender with sprung trucks; can be radio controlled. Dimensions (locomotive and tender together): length, 26 1/2″; width, 3 7⁄8″; height, 5 5⁄8″. In 1:32 scale, this works out to 70’8″ x 9’0″ x 15’0″, respectively

Pros: Attractive model; excellent representation of prototype; good level of detail, excellent finish, paint, and graphics; hand pump and axle pump with bypass system; excellent running characteristics; audible exhaust beat; fire not too loud; long duration

Cons: Drain-cock levers too stiff; safety valve not easily accessible; shiny wheel rims distracting

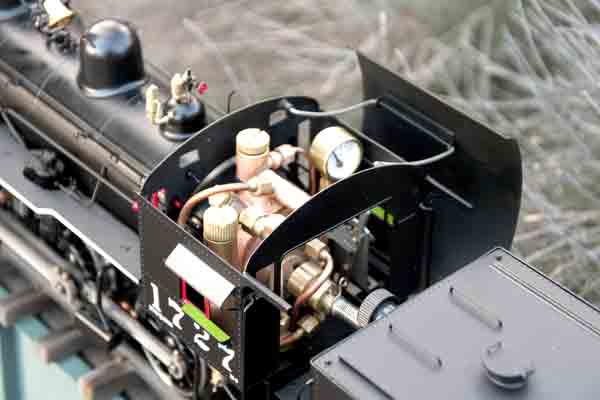

Sent for review is the live-steam version. The engine is also available electrically powered. Accucraft’s model is a faithful reproduction of the prototype. The locomotive features all-metal construction and is fitted with a single flue, gas-fired boiler. Boiler fittings include the throttle, safety valve (under a dome), water glass, filler plug, check valve, bypass valve, and pressure gauge. The interior of the cab is accessed via the swing-over cab roof.

The reversing lever is relatively easy to get to but the throttle lever is somewhat eclipsed by the cab’s back sheet. It can be opened about 30° through the back of the cab—any more than that must be done by raising the roof. The roof must also be lifted to read the pressure gauge. The water glass, though, can be easily seen through the back of the cab. A large displacement lubricator is situated next to the fireman’s side window. A boiler filler plug sits atop the throttle to the engine turret.

An axle pump is fitted, driven off the first axle, and there’s a bypass valve under the engineer’s side of the cab. While this is easily to hand, it is a little unsightly. If it and its attendant plumbing were painted black, it would look more a part of the engine.

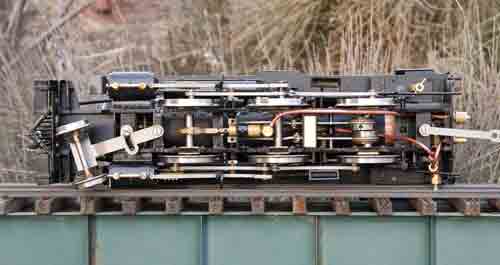

The detail level is good. Not everything on the prototype has been included but the important bits are there—it looks right. The drivers are all sprung and the springs are soft enough to be functional.

The prototype engine was equipped with Stephenson’s valve gear between the frames. The model simulates that with a pair of eccentrics and reversing links, which are controlled by a reversing lever in the cab.

Cylinders are fitted with working drain cocks. These are manually actuated by little levers under the cylinders. When you first start out, open the cocks to relieve hydraulic pressure in the cylinders. When the cylinders warm up, close the drains. I found the levers on this engine to be quite stiff and difficult to operate.

The engine is furnished with a Vanderbilt tender. A good-size gas tank is housed in what would have been the oil bunker on the prototype. And, like the prototype, the rest of the tender is given over to water. A hand pump resides under a simulated wood walkway atop the water tank. The walkway hinges up for access to the pump. The tender’s trucks are sprung with coil springs, hidden behind the dummy leaf springs.

Supplied with the engine are various wrenches, extra screws, and a pump handle for the tender pump. Two syringes—a small one for steam oil and a large one for water—are also included, as are a pair of cotton driving gloves. There’s also an extra water glass, should something befall the original.

To get it running, you must first properly couple the locomotive to the tender. Water feed and return lines must be connected. These are built into the tender and are simply pushed onto the barbed spigots under the cab’s footplate. The drawbar on the locomotive has two holes for the tender pin. If you want to connect to the second, for closer coupling, you’ll probably have to trim the water lines a little. Last, the gas jet, attached to a metal-bound hose connecting to the gas tank in the tender, is inserted into the flue end in the backhead.

Once together, the engine and tender must be handled as a unit. This isn’t difficult—the engine is a convenient size and both it and the tender can be easily gripped. Water can be added to the boiler two ways: through the filler plug atop the throttle turret or via the hand pump in the tender. The filler plug is quicker but the pump can be used while the engine is standing, under pressure.

The gas tank is filled in the usual way, through the little hatch atop the dummy oil bunker. It’s a fairly large tank that takes a lot of gas. The lubricator is also straightforward. If you’ve been running a while, the lubricator can be emptied via the drain under the cab floor. Water is added to the tender via the flip-up hatch on the water tank.

The weather on review day was still and cool, with temps in the 40s. Once I had the engine fueled, lubed, and watered, I opened the smokebox door, struck a fire, and opened the gas valve on the front of the tender. The flame immediately flashed back into the flue and burned steadily. Pressure came up in 8-10 minutes, which I thought quite good, given the coolness of the day. I opened the bypass valve, cutting out the axle pump so that water would not be pumped into the boiler while the engine was in motion.

This locomotive is equipped with working cylinder drain cocks. These are actuated by little levers, one under each cylinder. On our review sample, one of these was so stiff it was difficult to work at all. The other worked a little more smoothly. With pressure up, I opened the drain cocks, then cracked the throttle. Steam and water immediately started issuing from the cocks. I still had to push the engine to get it going but the cylinders cleared easily. Once warm, the engine took off on its own. I let it run one lap with the drain cocks open, then closed them for the duration of the run.

This engine is a joy. It is a strong, smooth runner with a nice, audible exhaust beat. The roar of the fire is so low as to be almost unnoticeable. It’s easily controllable, though throttle access is a little tricky due to the placement of the lever near the top of the cab. Getting the locomotive to run at a prototypical speed, without a train, was a snap.

At around 25 minutes into the run the water in the boiler was running low, so I closed the bypass valve, thus cutting in the axle pump. After eight minutes or so, the water level had come up in the glass nicely, so I opened the valve again to stop the flow. With practice and good locomotive management, adjusting the valve so that the flow of water into the boiler matches its consumption, thus maintaining an even water level, should be achieveable without difficulty.

The run lasted 45 minutes, once steam was up, before the gas ran out. The engine performed beautifully the entire time and ran equally well in both directions. Since it is a fully featured locomotive, with all the attendant complexity of same, I don’t think it would be suitable for the greenest beginner. However, if you have even a little steam experience under your belt, stepping up to this engine should be a pleasure as well as a good learning experience. This is a fine, well-made model. It’s a good representation of a distinctive prototype and is a superb runner that should provide years of pleasure.