Operations on the garden railroad: Operations on model railroads simulate the type of railroading that gets work done – moving cargo and passengers like full-scale railroads. “Ops” in the garden railway extends the social appeal of your yard, giving folks a fun activity. This introduction more than outlines the various railway jobs, such as engineer, dispatcher and yardmaster. This online version gives potential operators 400% more information than the hard-copy version. Would you like your guests to graduate from passive spectators to interactive team-members? Now some of us are retrofitting our existing railways to enable ops sessions.

Experienced or novice

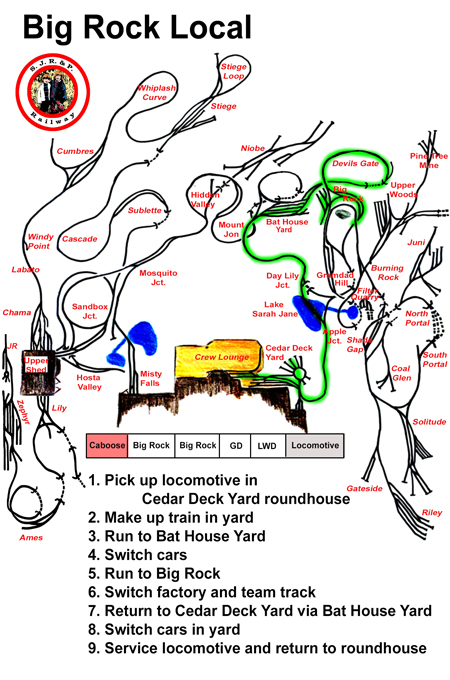

Stan and Deb Ames and a crew of dozens of operators have been refining the art of railroad operations for thirty years (photo 1). I’m indebted to Stan for helping me put together this story by defining job positions on their large-scale railroad in Massachusetts, the SJR&P. The crew tells their stories in the Regional reports. Only here can you read all of the stories, including three additional reports by two rookies and a gauntlet operator.

My first stab at ops was on my fellow club-member’s Lone Pine and Tonopah Railway. Superintendent Kermit Paul gave me orders to unload 6 freight cars from two tracks on a ferry. Using a handheld radio transmitter and a screwdriver to uncouple cars, I pulled off cars one at a time, alternating sides to keep the ferry from tipping. I delivered each to different destinations while sharing the mainline with several other operators – a 4-dimensional puzzle!

Infrastructure

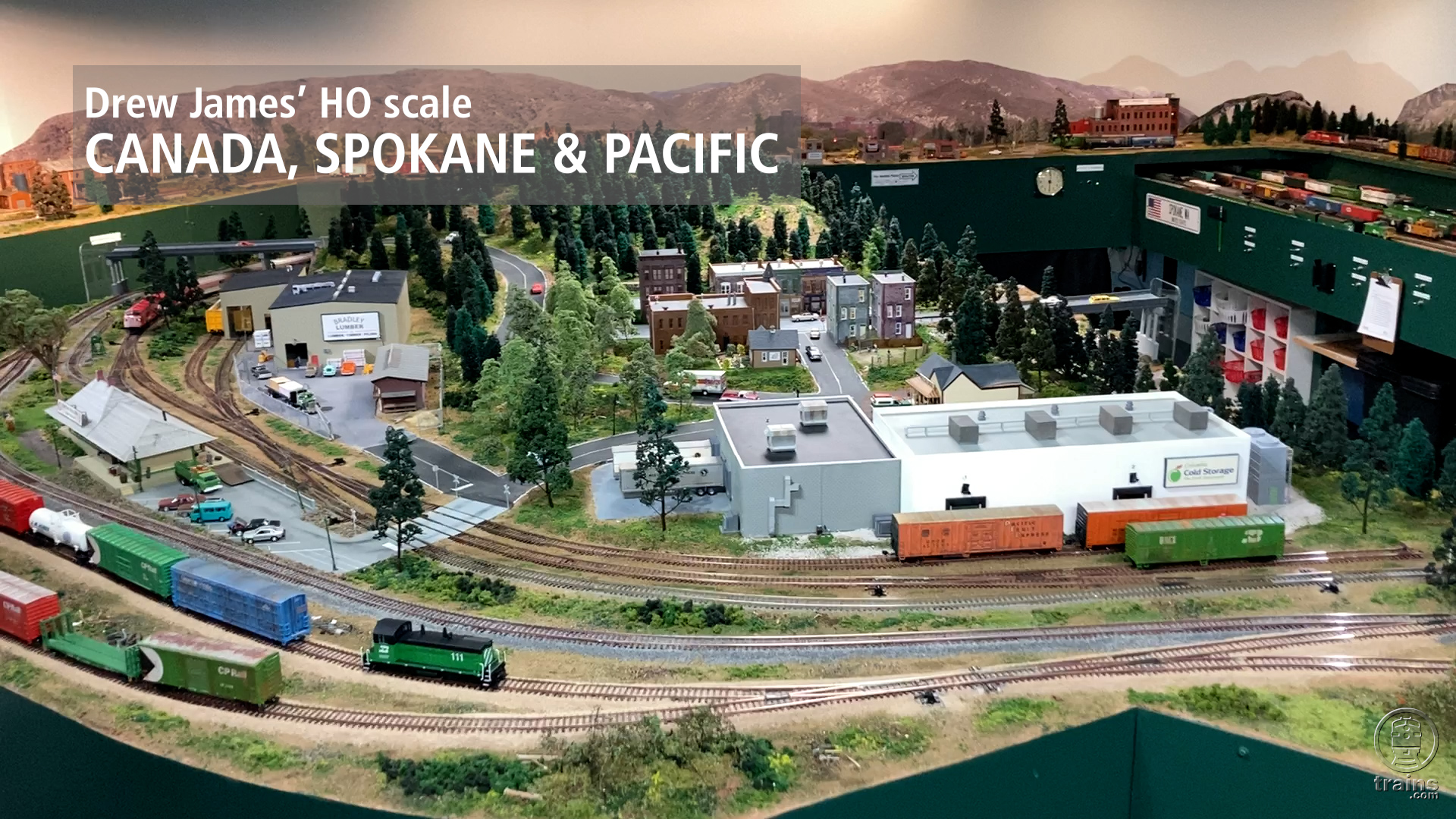

Civil engineers warn against the pitfalls of too-steep grades. Trains can climb slopes if builders keep the grade manageable for the engines. Longer runs lower the grade (rise over run = percentage of grade). Outdoors, those long runs (to keep the grade low) provide more space for sidings and yards (photo 2). You may be able to pull long trains up a steep grade for a few runs, but you may burn out your engine’s motor or strip some gears. Still too steep? Trevor Park uses a helper engine: https://youtu.be/2lPDnICV2k4

Retrofit

Adding sidings with appropriate industrial cars has made my railroad more authentic, unique to my theme, and useful for ops. Crossover switches on the parallel dogbone tracks allow the train to turn around. I still need to put signage on buildings that populate each yard so that train crews know where to deliver goods.

Stan Ames visited my railway and showed me how to turn my loop into a linear, point-to-point layout, more like the prototypical countryside with a cargo origin at one end and destinations/stations down the line and back again. By placing a brick (!) on the mainline during the ops session, I can remap the railway (from loop to linear). Operations are slow and careful. See his linear schematic in the Regional reports (photo 4.1). Ray Turner tells his story of transition to operations on his website: http://www.mysticmountainarts.com/MMRR/Operations/Operations.html

Garden design

In photo 1 trains use bridges and tunnels, but humans use paths and steps. Keep your rails safe on splines, or use wooden or concrete sub-roadbed, hidden by ballast (see Scott Gould’s roadbed). Hardened-roadbed edges protect the track (photos 1,3), here powered by 10-gauge stranded cable buried underneath and bused to their strong stainless steel rails in a parallel circuit. Search GR website for their “Ground-level roadbed”. Deb Ames mixed the concrete for most of that roadbed structure. It’s built to drain the groundwater so that freezing won’t heave up the base and sides.

Between train yards, Deb planted shade-lovers in her Zone 6 woods with beds of blooming hostas (Hosta spp., Zones 3-10) and fringed bleeding heart (Dicentra eximia, Zones 3-9). Sweet woodruff (Galium odoratum, Zones 4-9) greens up the rock portal. These herbaceous perennials will need removal of last season’s foliage in the spring plus some fertilizer once or twice a year. Tree leaves add mulch. The woody vine, wintercreeper (Euonymus fortunei ‘Kewensis’ Zones 4-9), climbs retaining walls.

Build it & they will come

Media:

DVD/digital archive of Garden Railways magazines

GR search bar: a wealth of reading/watching by typing “operations”

Books on operations or realistic model railroads + more books on Industries https://kalmbachhobbystore.com

Opsig book, …Operations (photo at right). Buy at opsig.org.

“A sectional urban switching district” Model Railroad Planning 2017

“Planning a classification yard for your model railroad” https://www.thespruce.com/planning-classification-yard-model-railroad-2382010

12 GR magazine stories on operations

Eric Lloyd, “Operations on the L.C.R.R” Jan. 1987

Jack Ray, “Crewchester: Operations…” July 1988

Jack Ray, “A return visit to the Crewchester Railway”, Nov. 1990

Jim Strong, “Freight-hauling operations…” May 1994

Kevin Strong, “Operations on the Middleboro Railroad” Dec. 2003

Jack Verducci, “Realistic train operations” Apr.-Oct. 2006

Marshall & Weylin Rose, “Triple Falls Lumber & Mining…” Feb. 2010

Ian Stringer, “Operations with a purpose” Apr. 2011

Steve Blackson, “A well-developed trackplan…operation” Aug. 2011

Donald & Jane Nute, “Operation with young railroaders” Apr. 2014

Jack Verducci, “Make a basic cattle chute…” Oct. 2016

Kevin Strong, “Building the Tuscarora RR” Feb. 2017

Videos and slideshows

Stan Ames’ Operations slideshow

NMRA. Dave Adams “Lessons learned” slideshow

For some, simulation is just a step toward working on full-scale railroads. I’ve watched kids graduate from the garden railroad to working on the prototypes. To learn about standardized operating rules, read Dennis Winger’s story about an operations course (GCOR) you can take. Search online for excursion trains in your state where you can operate. (Hint: volunteers get first dibs.)

Conversely, run full-scale to better model ops on your scale railway. Stan Ames and son regularly sign up for operations on full-scale railways, mostly steam-powered: “I found that the experience on the prototype has helped shape the way we operate on our railroad” (photo 1.6 in Regional reports). There are lots of places you can be an engineer for a day. The problem with these courses is that you only get a very short time at the throttle.”

What Stan has found after many years at this, is that on the first run each year he makes lots of mistakes. By the second run it all returns and he relaxes a lot more. It’s a steep curve for first time operators and on the first run it is mostly getting used to operating. By the second or third run you really get a feel for both the run and the locomotive. No two steam locomotives are the same. Each has its own characteristics that you need to get accustomed to.

Once a year Stan runs full-size steam locomotives in one of two locations. In the US, The Cumbres and Toltec railroad in New Mexico and Colorado offers an engineer school: http://cumbrestoltec.com/engineer-fireman-school/ The first year you train as a fireman, the second year you run as an engineer. They also have an advanced school where you learn how to be a brakeman and switch cars. It’s a great mountain railroad and running a narrow gauge K-36 up and down the mountain is a lot of fun.

In Poland, the Wolsztyn Experience runs a program where students run standard gauge steam on actual scheduled passenger runs carrying paying passengers. Students operate large 2-8-2 and 2-6-2 locomotives at full track speed (50+mph) stopping at numerous stations along the route. http://www.thewolsztynexperience.org/

Manual vs. computer-assisted operations by Bob McCown and Stan Ames

On the SJR&P, generating the train schedule for the session and staging the railroad (positioning the cars and setting the waybills) is done prior to the start of operations manually. As each train is run, crews construct switchlists from the waybills for each run or simply use the waybills for less complex runs. Manually setting up operations allows the greatest flexibility but takes more time to set up. The use of waybills is also self-healing. If a car and its card go somewhere they don’t belong, the car will eventually work its way back to where it belongs.

In computer-assisted operations the computer generates the switchlists each time you want to run a train. Many in large scale use the operations module of JMRI for this purpose. JMRI is a giant program that does many things: Digital-Command-Control/DCC, signal interfacing with things like Bruce Chubb’s CMRI, or the NMRA’s NMRANet/OpenLCB, and operations.

Unlike car cards and waybills, using JMRI operations generates a train manifest/switchlist for what your train will be doing. When initially setting it up, you enter all your towns, industries, yards, etc. with siding capacities. Then you add all your rolling stock (and optionally locomotives). You then set up routes for a train to run.

At the beginning of a session the computer tells you where to place each car. Later in the session, each time you want to run a train, you ask the computer to ‘generate’ a switchlist for it. The switchlist tells you what cars at what town to pick up and set out. Unlike waybills switchlists are not self-healing. A misplaced car with switchlists becomes a game of “hunt the boxcar”. The other side of the coin is new operators don’t need to know where every town is on a layout. The switchlist tells them simply, “Go to the next town and pick up flatcar 1201”.

A bunch of us have distilled down how-to information in this thread:

http://www.largescalecentral.com/forums/topic/24208/getting-started-with-jmri or you can go to the source – JMRI:

http://jmri.sourceforge.net/help/en/package/jmri/jmrit/operations/Operations.shtml

Rookies – not for long

Photo 3 shows what’s needed in our hobby – youth! Quincy tells his ops story (10a) in Regional reports. See kids’ ops in GR’s cover story Apr 2014 (sidebar). Puzzle-like maneuvers give kids a game and our old brains a workout.

Stan says: “Our experience in recent years is that those who have expanded [their railways] into some form of operations tend to work more on their layouts and spend more time enjoying the hobby. The size of our layout may lead people to believe operations requires something large; in reality the small layouts can be just as much fun – fewer trains running at the same time, but just as fun. Operations on our railway are constantly evolving as we learn from our operators, from the prototype, and from other railroad operations. I suspect we will never learn it all.”

Here’s an article to help people who are just beginning to ease into operations: https://familygardentrains.com/primer/operations/operations.htm

Also my friend Wil Davis (of the Miami Valley Garden Railway Society) once told me: There is an excellent article in TRAINS magazine?s August issue [2006] on the Ohio Central and how they work to satisfy customer?s needs. In one case they deliver steel to a factory and actually shuttle the cars in and out of the warehouse while the customer unloads them.