Realistic operations on a raised railroad: In my first garden railroad, (see Garden Railways May-June 1990), The Great Lakes and Gazebo Railroad, the objective was to add interest to my garden, have fun around the pool, and engage my kids in a new way to play with Dad.

My new chapter had to include a railroad whose operations helped me expand my imagination. As it happens, a prototype railroad offered a story line that I could warm up to. It is not uncommon for unstable trestles to be reinforced by filling them. One such filled trestle exists north of Colchester, Connecticut and is now part of a scenic bike trail called the Skyline Scenic Area Trail.

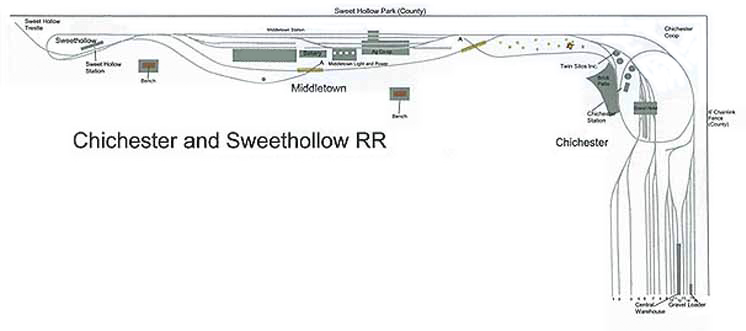

I imagined a condemned trestle, now subject to filling at the northern most point. The southern extreme was to be a gravel loader. A small percentage of the spoils drawn from a reservoir being built to service New York City were loaded into special side dumping hoppers. Like the prototype, gravel loaded in the south would be transported to fill Sweet Hollow Gorge. In the fashion of old Lionel dump cars, the action is electronically controlled from the watchful eyes of Sweet Hollow Tower.

The track is Sunset Valley code 250 stainless rail with nothing less than 8-foot radius curves. All switches are Sunset Valley. All switch motors are manual. All engines are battery powered, and radio controlled. Controls are both Airwire and Revolution. Rolling stock was converted to metal wheels and Kadee couplers.

Railroad operations

There are seven operating positions:

- Passenger loop.

- Freight from south depot to the transfer station.

- Gravel dump at Sweet Hollow Trestle.

- Switching south depot

- Switching the transfer station

- Picking up local grain/running the unit train.

- Bringing coal from south depot to the power plant, then bringing empties back to the depot from the plant.

The gravel train is our highest priority. The town of Middletown is the railroad terminus where freight is offloaded at Sweet Hollow Industrial Transfer Company and picked up by a fleet of waiting trucks.

Most of our terrain is rural in nature. Middletown is a bustling mill town with towering brick buildings, including the Transfer Co., a storage warehouse, a large power station, and a grain transfer station.

Grain is an important product coming from neighboring hills. Unit trains are being assembled at the grain transfer station where local cars and trucks are offloaded. Farmers who operate the local elevators are fearful that they will not have a way of getting their grain to market, protect their wood sided box cars jealously despite their temporary grain doors. A switcher assembles grain mules regularly bringing them to the depot to transfer their booty. Watchful elevator operators insist on an equal exchange of empties for loaded cars.

Freight traffic at the Transfer Co. is a full-time job. Four tracks supply the giant facility (348 scale feet long). The loading dock is arranged according to the type of goods it accepts or offloads. Freight cars must be placed in the appropriate order (frozen, food stuffs, hard goods, etc.) and stacked in double width (boards are placed from loading door to loading door to facilitate more efficient loading and unloading). Two operators are gainfully occupied as trains reach the terminus and exchange goods. Two switchers stationed at Middletown keep traffic moving.

While traffic terminates in the north, an 8 x 12 shed serves as an operating stub yard. It in turn is fed by a large yard split between northbound and southbound traffic. A train leaving on one side returns on the other after a day’s work. It gives an operator a greater sense of having travelled.

Roadbed and trestles

Our trestles, as well as a 50-foot-long viaduct, were made of Azec, a cellular PVC product, and are left outside to fend against the elements year round. Our raised roadbed consists of Azec 1 x 4s sandwiched on two sides of an Azec 2 x 2.

Depending on how high we are above grade, we use a PVC 2 x 2 driven into the ground below the frost line or a treated 4 x 4 buried below the frost line. The folks at Split Jaw Rail Clamps helped us create the look of a plate girder bridge by carving strips of half inch black PVC into realistic looking panels that appear to be plate girders.

Structures

Any kit that you find in HO scale is a one third model of the prototype in 1:29 scale. This has become an important element for us, especially in the construction of structures.

All structures are scratchbuilt using mainly Azec. (As a side note, Sherwin Williams makes paint products that adhere well to Azec.) All buildings have interiors, lighting systems, and custom sound.

Garden railroading has become a big part of my retirement plans. I am lucky to have support of family and friends that make everything about this wonderful hobby come to life.

The railway at a glance

Name: The Chichester and Sweet Hollow RR

Gauge: No. 1 (45mm)

Scale: 1:29

Type of track: Sunset Valley code 250 stainless rail

Minimum radius: 8 feet

Structures: Scratchbuilt

Control: Airwire and Revolution

That is amazing. Well done!

I always wondered if anyone did realistic operations on an outdoor railway. Wonderful!