When we acquire a small-scale live steamer, it is usually to run on an established garden railway. The selection of your live-steam locomotive was probably influenced by the physical characteristics of the existing railway. But what if it was the other way around; what if you could build a garden railway specifically for use by live steamers? What factors should you consider? Here are a few things to keep in mind.

Height

If you have a manually controlled, or coal- or alcohol-fired locomotives that need fueling during the course of run, I recommend that your garden railway be built as high as possible to minimize the discomfort of constantly bending over. Believe me, I’ve learned from experience that what was a “good” height for a garden railway built 15 years ago doesn’t seem as acceptable now that I am 15 years older! Once you have settled on the best height for your railway, make sure it is designed so that you can comfortably reach over to attend to your locomotive as well.

Gradients

In general, live steamers and electric locomotives are comparable in pulling power (for example, a live steam 0-4-0 will typically pull as much as an electric 0-4-0), but are more sensitive in terms of grades. This is not as much about pulling power as it is control of the steamer on the up and down grade. For manually controlled locomotives, a railway that is as flat as possible is recommended. The engine can be left to run on its own without you having to constantly chase it to adjust the throttle.

For radio-controlled locomotives, grades can be incorporated as part of the railway, since the throttle can be remotely adjusted to provide the steam required. Again, as gentle a grade as possible is recommended-remember, the steeper the grade, the shorter the train your locomotive will be able to pull.

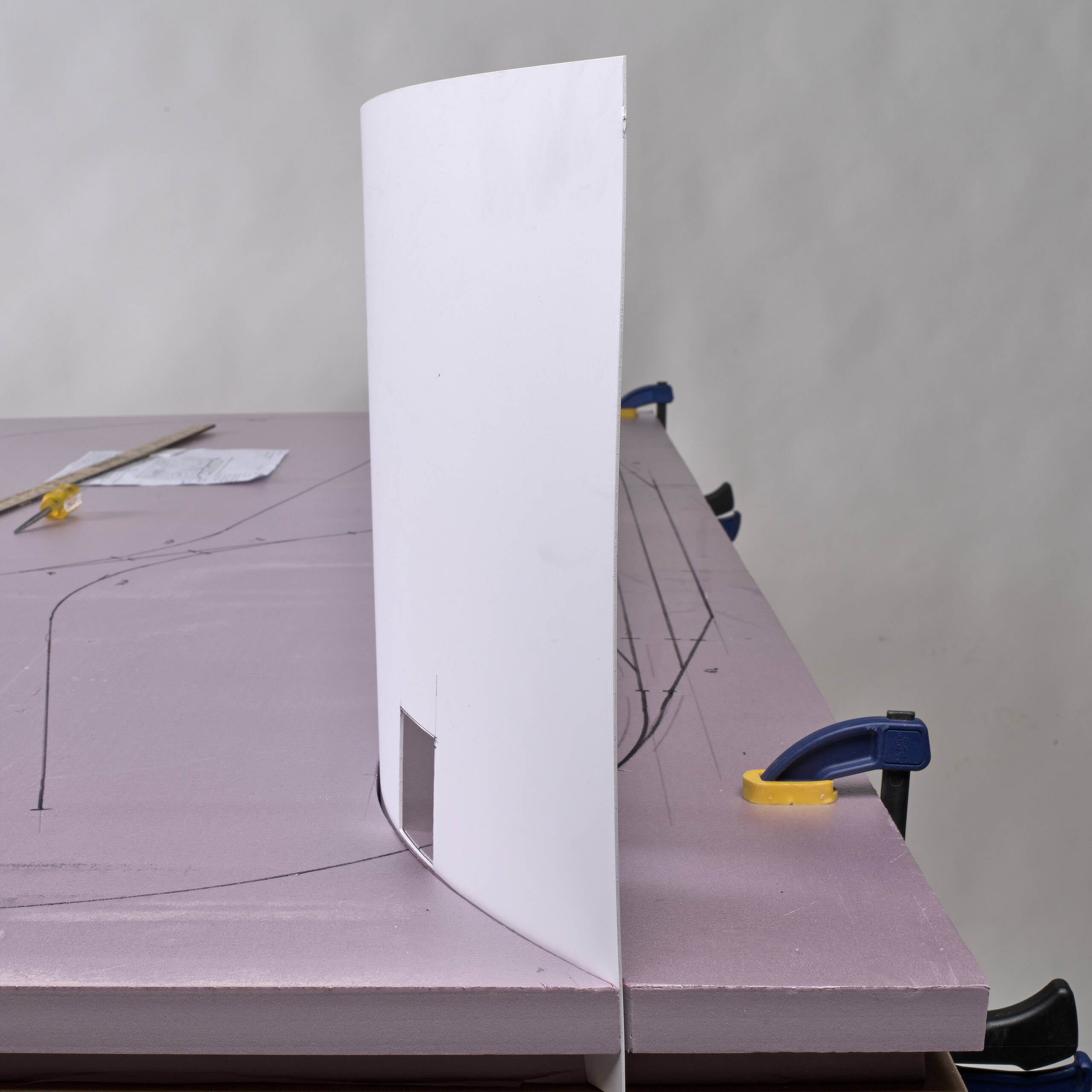

Although there are scientific equations to calculate theoretical pulling power of locomotives, some experimentation with your engine is best to determine its pulling power on grades. Test your locomotive with some cars on a length of track mounted to a long board, with one end raised with bricks. This will provide a quick way to determine the most acceptable gradient prior to actually building the railway. Remember, as well, that a grade on a curve limits the pulling power of the locomotive even more. If you are running live-steam Shays or other geared locomotives, you can probably use steeper grades, just as the prototype logging and mining railways once did.

Curve radius

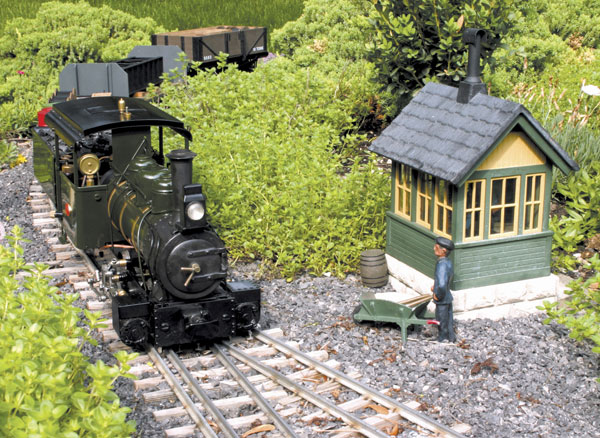

The minimum curve radius of the garden railway will be determined by the size of the largest locomotive expected to run on it. Obviously, a large 2-8-4 Berkshire will require broader curves than a small, industrial tank engine. Also, the speed of the locomotive comes into play in the curve design. A 1:32 scale, gauge-1 model of a steam locomotive pulling a 10-car express passenger train will need large curves-say 10′ radius or bigger. Such a majestic train, running at full speed, just looks better (and stays on the track better) on the broadest possible curves, so bigger is better in this instance.

Locomotive servicing

Don’t forget to incorporate a steaming bay. In the April 2005 issue of GR I discussed the steaming bay and its requirements. One idea that I’ve always thought would be interesting to incorporate in a garden railway would been an engine-servicing facility that functions the same as on a full-size railway. In other words, the locomotive would get its water from a water tower, receive fuel on ready track, then depart for service. Upon its return at the end of the run, it would drop the fire over the ash pit (literally, if it is coal-fired model), blow down the boiler, be turned on the turntable, and be put away in its roundhouse stall.