In 2020, MTH Electric Trains President Mike Wolf announced his May 2021 retirement and the subsequent closure of the company after 40 years in business. It’s now 2025, and MTH remains alive and well, continuing to produce products for the model railroad and toy train industry at a more modest pace in O, Standard, and Gauge-1 scales — both the HO and S scale tooling were sold to ScaleTrains.com in 2021. Rich Foster, Vice President of Sales; and Bradley Deleon, a member of MTH’s staff, remotely joined Classic Toy Trains Editor Rene Schweitzer and Trains.com Staff Writer Lucas Iverson for a behind-the-scenes chat about the company’s new chapter.

Watch the extended video recording of this interview with MTH on Trains.com Video

Q: What were the factors in deciding to keep MTH operating and producing model/toy train products?

Rich: [Mike Wolf’s initial retirement] was obviously within the very early days of COVID-19, which left a lot of uncertainty about whether any business could survive. So, we had some inquiries from people he was looking to sell the whole business to, if possible.

We didn’t have a whole lot of tooling in HO or S scale, so that got moved fairly quickly because the total dollars required for that were fairly low. But we probably had more O gauge tooling than the rest of the market combined, so everybody was unsure about making that kind of commitment, dollar-wise. As it turned out, we sold some of that to Atlas and Lionel.

Meanwhile, I’d been working on a plan in case somebody did buy the business, as I was hoping to keep the job. That led toward me working on a new business plan, to some degree. I showed it to Mike, as it basically lowered the overhead with potentially less headaches. He decided he was willing to go forward with the plan, and that’s why we kept going.

Q: Can you explain how the business changed to what it is now?

Rich: What we basically decided to do was reduce the staff and the overheads fairly significantly. The good news was we were able to keep a lot of our more experienced people as contractors. They wanted to continue working on what they knew how to do.

Q: Looking back, were there significant challenges during the transition?

Rich: There were challenges because as soon as you get down to where you’ve got fewer employees, people need to do some things that they weren’t used to doing in the past. But it’s been fine overall. It allows us to wear some hats that we might not have worn five years ago.

Q: In the past year, MTH started releasing Tinplate Traditions and RailKing One Gauge products again. What does the future hold for those lines?

Rich: I would think with either of them, but particularly Tinplate, we’re going to have to see because we’re just about to deliver some of the first items from five-plus years ago. Depending upon the responses and popularity, that’s going to drive what we do moving forward, obviously.

The One Gauge products have so far been pretty good. We’ve invested in two new toolings for the SD70ACe and ES44AC diesels, which weren’t cheap. So we plan on staying committed to that line.

The Tinplate is going to somewhat depend on how well the monorail and 400E steam locomotive do. We’re even about to promote some passenger cars to go behind the latter. Obviously, Mike loves Tinplate. That was his passion and what started the business. So I’m sure it wouldn’t take a lot of coaxing to get him to stick behind it.

Q: What led to the partnership with Atlas and the current collaboration with the manufacturer?

Rich: A lot of it stems from way back to when they bought some of our tooling. Mike offered to Atlas the service of putting MTH’s electronics into the tooling that were bought. Right there, you have a hybrid-type working relationship.

There are things that they want to do or we want to do, because the other company owns a particular tooling or whatnot. But it’s more of a partnership in general, and has to make sense for both companies to do a certain project. You will likely see more of something like that from time to time in the future.

Q: What’s been the feedback from customers so far about the collaboration?

Rich: I think it’s good. It can get a little confusing, and you have to do some explaining at times, especially to the dealers. But overall, I think they’re happy.

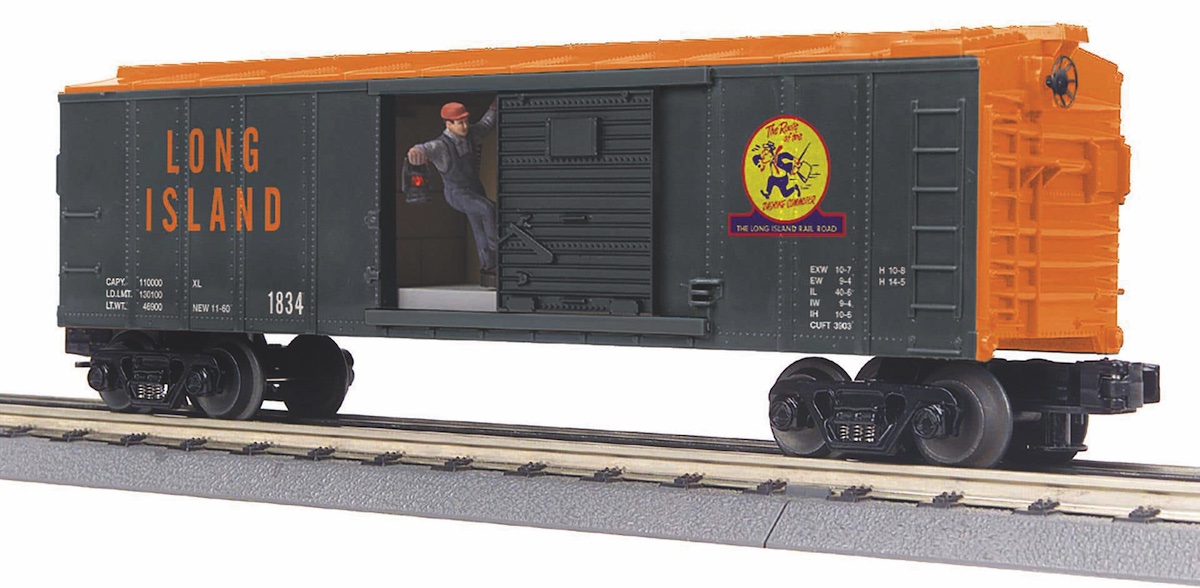

Q: Let’s say a club or dealer reaches out to you, wanting to make a custom-run product. Can you explain the process of how this comes together?

Rich: When we promote a particular item, we start getting inquiries. We tend to get as much information on the front end for what they want, and then tell them the basic quantities. We offer to do some things that I think help make the whole request more palatable, such as multiple car numbers on a particular road name. Certain customers will want multiple cars with unique car numbers.

Other times, we’ll get inquiries about a product we have not promoted yet. We’ll have dealers or clubs ask us, “When you run item x, y, and z again, can we jump in on a custom run of it?” Often, that drives what we’re going to be promoting in the near future.

It kind of goes both ways. But overall, it’s dealers or clubs that get with us, provide images that they want, and we give them the opportunity to pick the car numbers. They have an opportunity to tweak the artwork, and once they approve it, it goes into the mix of being built and delivered to them as soon as we can get it done.

Bradley: On top of that, it doesn’t just have to be a dealer or model railroad club. We also work with enrichment clubs, societies, and other smaller clubs. We even have a bakery in Pennsylvania that requests custom runs. So we’re open to any inquiries on those.

Q: What do you wish our readers knew about MTH?

Rich: I think we have a reputation for offering high-quality products at an affordable price, as best we can in this industry. We do keep our overall overhead lower. It costs a lot of money to print those catalogs and mail them two-times a year. But the way technology is now, it allows us to do these weekly newsletters.

Q: What does the future hold for MTH?

Rich: We’re going to keep building trains. We’re going to keep making stuff. Having Bradley on board has breathed new life into this place. He’s very good with the customers, really tries to help people, and is learning every day on the job. Because this is a strange industry to jump into if you haven’t been involved in it, there are nuances which will take a lot to figure out. But he’s doing great.

Bradley: I’ve noticed that the younger generation is way more into prototypical scale stuff from talking to them. So, we’ve worked with a lot of them, and I would go onto Discord chats and monitor in the background. They don’t know that it’s me, but I just try to absorb all the information I can. I also try to go to other outlets like Facebook and the O Gauge Railroading Forums to soak up all I can.

Q: Any possibility for growth again?

Rich: Yes. Since Bradley’s been on board, we have quite a few new toolings in motive power and rolling stock, which are going to be announced soon. Right there, once you start spending that kind of money and invest, you better put it to good use. I’ve been with this company for 37 years, so there’s probably a limited future with me being in charge of anything. Now that I’ve got somebody who is younger and smarter than I am, he can take over and run with it.