No doubt about it, trains run better when you keep the rails clean. There are many commercial products on the market that get the job done, but when I clean my O gauge layout (see “Postwar gem in 55 square feet” in the November 2012 issue of Classic Toy Trains), I reach for my homemade track cleaner.

This handy little tool is made from simple wood shapes and uses a microfiber cloth pad to easily and effectively clean dirty track. Follow along as I show how you can make your own track cleaner.

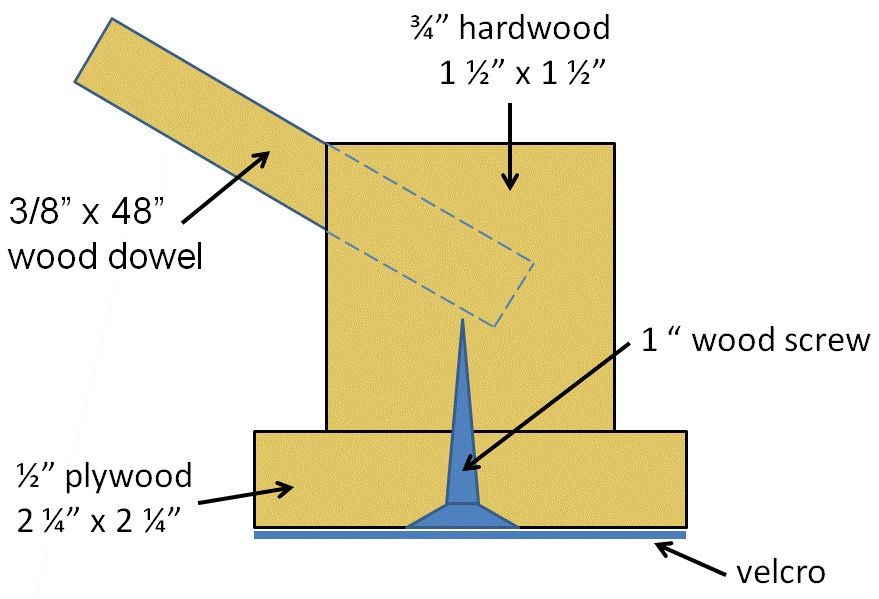

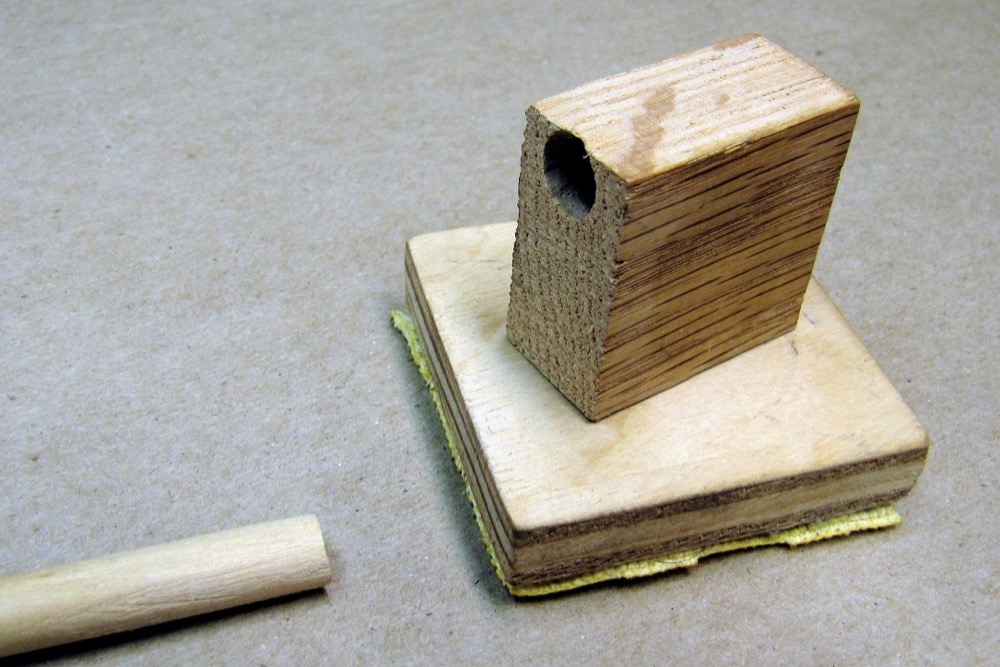

I started by cutting a 1½ x 1½-inch block from a piece of ¾-inch hardwood and a 2¼ x 2¼-inch piece of ½-inch plywood. I then drilled a hole in the center of the plywood block and into the hardwood block to accept a 1-inch-long flathead wood screw. I recessed the hole to allow the screw head to sit flush with the surface of the wood.

Because I wanted the plywood base to rotate easily so dirt and debris would be distributed evenly over the whole face of the cloth, I didn’t fully tighten the screw.

Next I attached lengths of Velcro brand hook-and-loop fastening tape. Velcro, commonly available at craft and home improvement stores, has a soft loop side and a sharp hook side. I glued pieces of the hook side to the plywood base.

I next turned my attention to making a handle. Using a ⅜-inch drill bit, I made a hole partway into the hardwood block at about a 30-degree downward-sloping angle.

A 4-foot ⅜-inch dowel fits snuggly and allows me to reach the more remote areas of my O gauge railroad. I remove the dowel when I clean the track at the front of the layout.

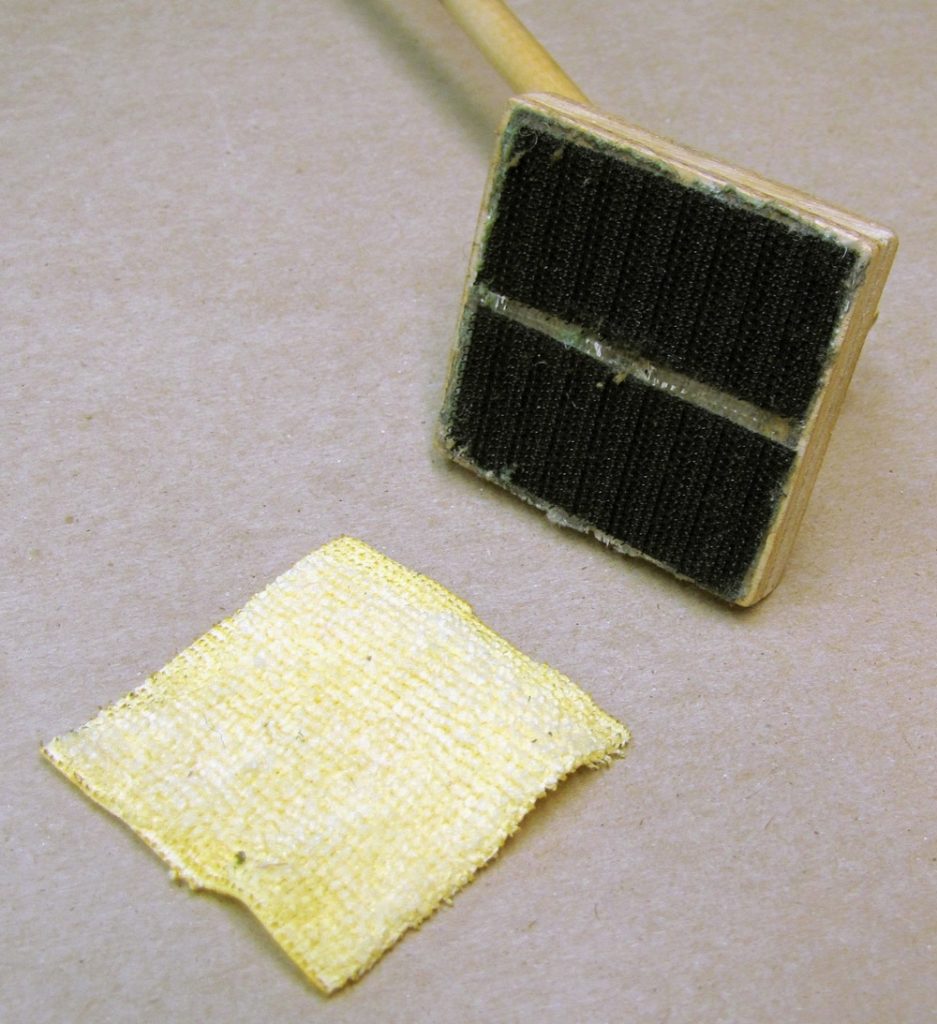

Finally, I purchased microfiber cleaning cloths from a local discount store. Microfiber cleaning cloth is an amazing synthetic polyester material that traps dirt and debris without the use of liquids.

The cloth is difficult to cut cleanly with scissors so I use a sharp hobby knife and straightedge to cut the cloth into 2¼-inch-squares. Since the cloth is a synthetic material, I recommend sealing the cut edges by briefly passing them through the flame of a cigarette lighter.

I like to cut the entire cloth into sections at one time. This may seem like a lot of work, but once you cut up and seal an entire package of microfiber, you’ll have a supply that will last for years.

The cloth adheres well to the Velcro hooks. You can use both sides of each cloth, and the material can also be washed and reused if you wish.

Dry microfiber pads seem to work fine, so I don’t bother wetting the material with track-cleaning fluid.

Now you’re ready to put your tool to the test. Allow the base to rotate randomly so the dirt is picked up evenly. You’ll find the cloth will soon turn black. When it gets really filthy, just flip the cloth over so that both sides are used. Happy cleaning!