Traction tires have only recently become the norm in a world once ruled by Lionel’s Magne-Traction. These days, if you run modern-era trains a lot, you’ll end up with a tire that has worn smooth, broken, or simply been thrown off, usually exposing a grooved steel rim that insists you fill it with a good tire.

There’s the rub. The task actually looks quite simple, but the challenge is that traction tires fit tightly, and that means you usually have to strrrretch them to wrap them around their rims.

Here’s a method I used recently to replace a traction tire on a K-Line Pacific steamer that will help you with any brand of modern steam, diesel, or electric locomotive.

1. Place the locomotive upside down in a foam cradle or a cloth-lined tray to protect it and hold it steady still while you work.

2. Remove just enough of the steam locomotive’s running gear to let you slip the replacement tire around the rim. If the tire goes on the rear-most drive wheel, you’ll only have to remove one hex screw on that driver. To remove hex screws, buy a 1/4-inch socket set that contains both inch and millimeter sockets. Don’t use a pair of pliers or vise grips; you’ll damage the head of the hex screw. If the traction tire goes on a center driver or a front driver, you will need to disassemble more pieces. Always work on one side at a time, never work on both at once. Working one side at a time will keep the wheels properly quartered. It also allows you to reassemble the running gear using the untouched side as a guide.

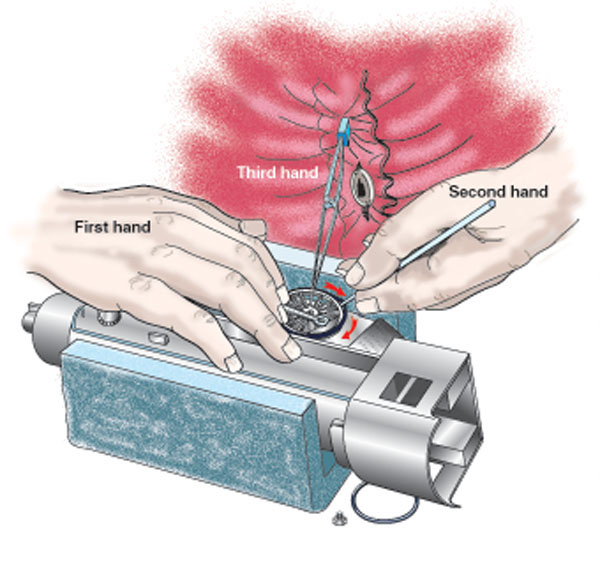

3. Slip the tire in position and push it as much as you can into the gap between the driver needing the traction tire and its neighboring wheel. Once you got the tire in nice and flush, hold it firmly with two fingers, straddling the dangling siderod, if need be.

4. With a pair of tweezers or a similar tool in your other hand, stretch the traction tire around a third of the rim in any direction.

5. Here’s the tricky part. Wedge the tweezers between the flange and something else (I used my padded stomach) to hold the tweezers steady. You have now found a third hand. Don’t feel bad – in fact, laugh, if you can – if you don’t get everything to stay in place the first time. Or the second time. Or even the third time. You’re in good company.

6. Using a tool with a small round handle (I used a small round file), roll the rest of the tire onto the rim. You’ll find that once you get about another third of the way around the rim, the final third of the tire almost seats itself.

7. Carefully withdraw your fingers and the tools from the seated tire and press fit the tire fully into the rim’s groove. Make sure the flexible tire isn’t twisted on the rim.

8. Reassemble the running gear and carefully allow the tire to set itself in place as you run the locomotive slowly on your layout.

That’s pretty much the third-hand trick. For diesels and electric profile locomotives, the task is similar. Of course, you don’t have any running gear to remove, but you may have to remove the truck sideframe to gain clear access to the wheel rim.

When you’re done replacing the traction tire and your locomotive is once again steaming around your layout, smile broadly. You deserve it.

has anyone answered how the traction tires are installed on diesels ? Obviously the trick is dismantling the truck, but tips on that process would be appreciated

Where does one purchase replacement traction tires? I know MTH sells them however they are quite pricey through MTH. I saw the new catalog offers a "kit" for almost $400.00 including traction tires and everything else "repairs" under the sun however all I want is a "Traction Tire Kit". Any suggestions?

Was the question of where to obtain rubber tires answered?

Thanks from a new member.

San Diego Frank

I have less trouble replacing tires than finding them. Is there a generic source if we know the diameter of the driver?

How do you put rubber tires on lionel diesels. Thanx

I wonder how one removes the hex screw. Using the socket, do you just try to turn it to the left? How do you keep the wheel from moving whilst doing so?

It might be a good idea to seal in old traction tires with a little

Bullfrog snot. It, of course, can also help with engines that have

no traction tires. My flyer 282 and 356 had no tires and couldn't

pull more than two cars up a grade, but after I snotted them I felt

they could pull a REAL car.