While David and Co. continue construction on the N scale project layout, Steve Sweeney shares his techniques for assembling a cardstock house kit. Follow along, as Steve walks and talks you through all of the essential tools, supplies, and processes — start to finish! […]

Read More…

The year 1952 was a spectacular one for Lionel operating toy train accessories. An enduring favorite to come out of it was the no. 362 barrel loader. Professor Carp gives the history of the item and discusses changes and variations, while Classic Toy Trains Editor Hal Miller looks at how it operates. You can get […]

Read More…

The year 1952 was a spectacular one for Lionel operating toy train accessories. An enduring favorite to come out of it was the no. 362 barrel loader. Professor Carp gives the history of the item and discusses changes and variations, while Classic Toy Trains Editor Hal Miller looks at how it operates. You can get […]

Read More…

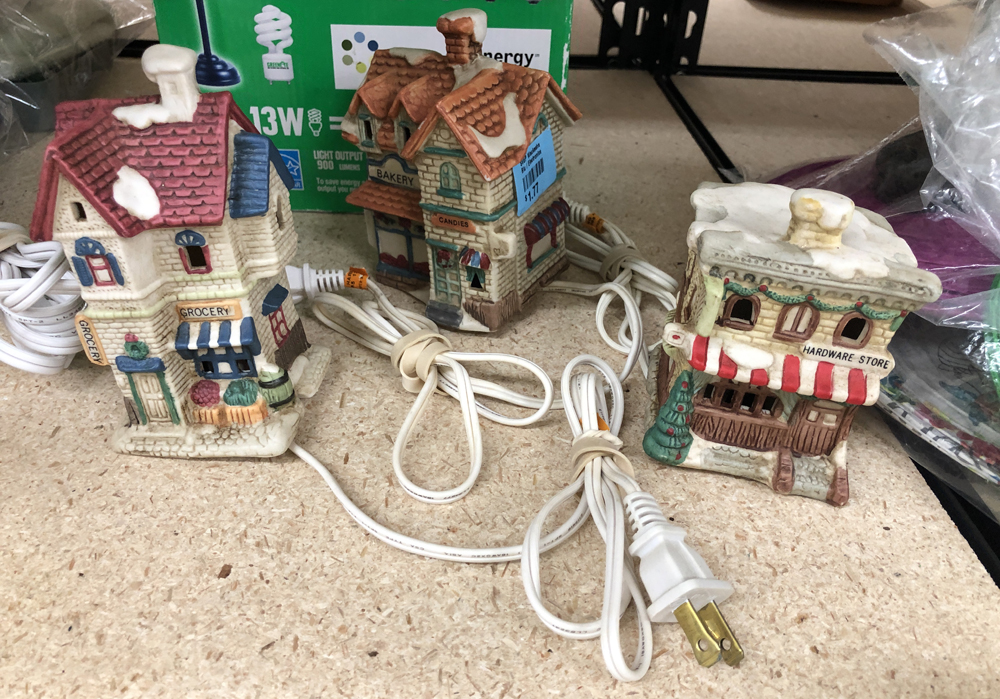

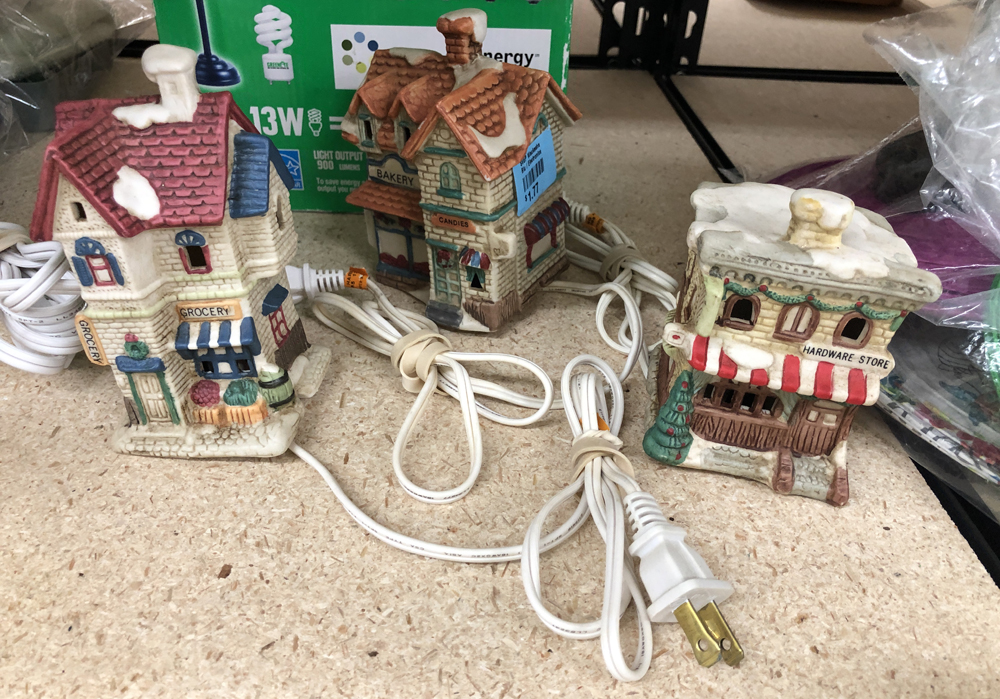

Thrift stores can hold a wealth of treasures for hobbyists, if you know where to look. I have suggestions of which departments to look for items for your layout. I suggest going into a store with an open mind. For just a few dollars and a maybe a bit of paint, you might find something […]

Read More…

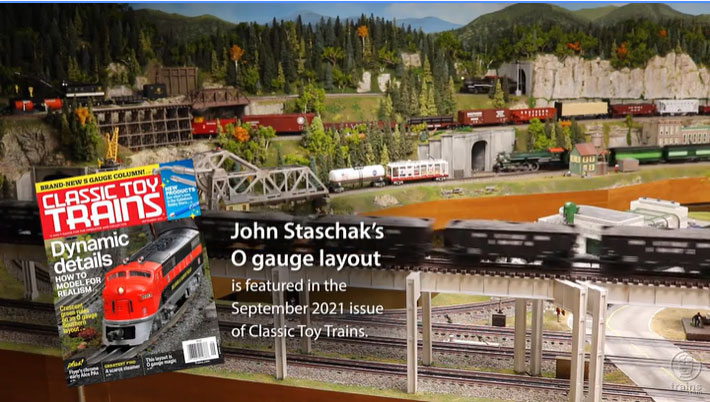

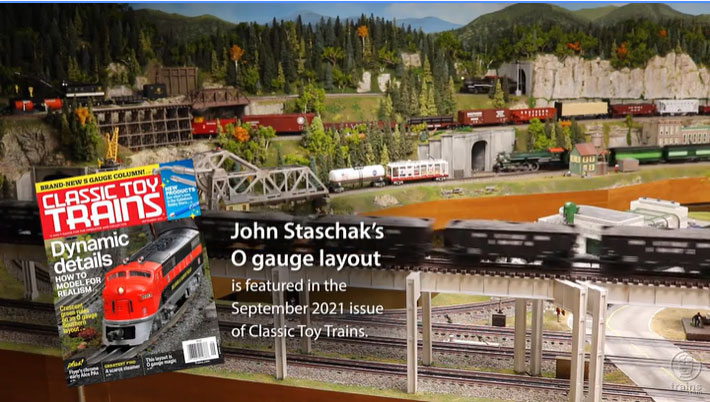

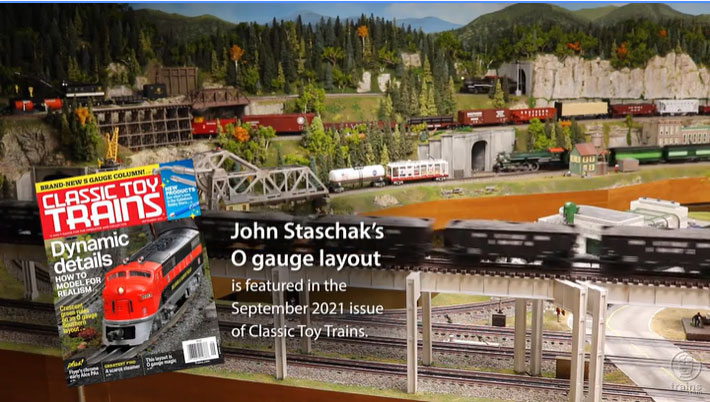

John’s layout appears in the September 2021 issue of Classic Toy Trains. It features tremendous trackwork and wonderful scenery (see the plan here), in addition to some spectacular modern trains. Watch and hear freight and passenger consists work their way around it. […]

Read More…

John’s layout appears in the September 2021 issue of Classic Toy Trains. It features tremendous trackwork and wonderful scenery (see the plan here), in addition to some spectacular modern trains. Watch and hear freight and passenger consists work their way around it. […]

Read More…

“Projecting” signs have been part of the commercial landscape for years. In the early years of the 20th century, they often consisted of boards jutting out from the front of buildings with the business name on both sides. They’re also referred to as “blade” or “flag-mounted” signs. I wanted to model projecting signs in my […]

Read More…

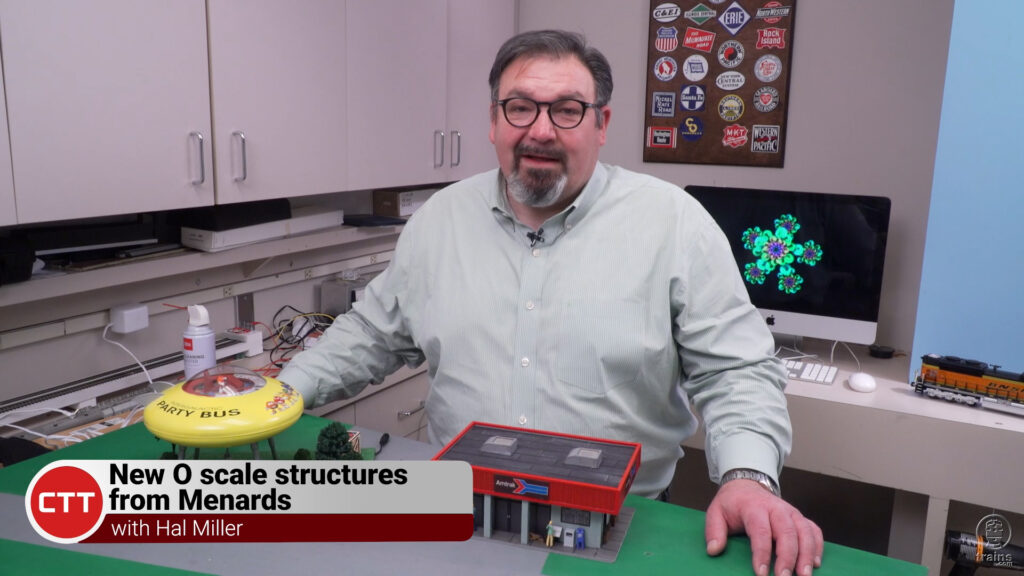

CTT editor Hal Miller takes a look at some recent accessory offerings from Menard’s, including the no. 2784523 O scale Amtrak station, and the 2796130 M&Ms UFO scene. Both have a lot of features that give them a ton of play value! […]

Read More…

Hal Miller continues his Workbench Minute series showing how to clean a Lionel no. 97 elevator. He uses a cleanser that’s both safe for his skin and the model to wipe away decades of dust and grime. […]

Read More…

Hal Miller continues his Workbench Minute series showing how to clean a Lionel no. 97 elevator. He uses a cleanser that’s both safe for his skin and the model to wipe away decades of dust and grime. […]

Read More…

Facts & figures Price: $39.98 Manufacturer Wm. K. Walthers Inc. 5601 W. Florist Ave. Milwaukee, WI 53218 walthers.com Era: 1940s-present Features Art Deco styling Footprint: 6.875” x 7.875” Full-color decal signs Injection-molded plastic in three colors plus clear Where do all those ’57 Fords on your layout come from? If you model in HO […]

Read More…

Our local Michaels craft store sells an unfinished wooden birdhouse you can buy for just $4.99 (or less if you use a coupon). I’ve found it useful for kitbashing small buildings for your railroad. I will share three examples I made for my own railroad. [Note: All unfinished wood should be painted/stained before leaving […]

Read More…