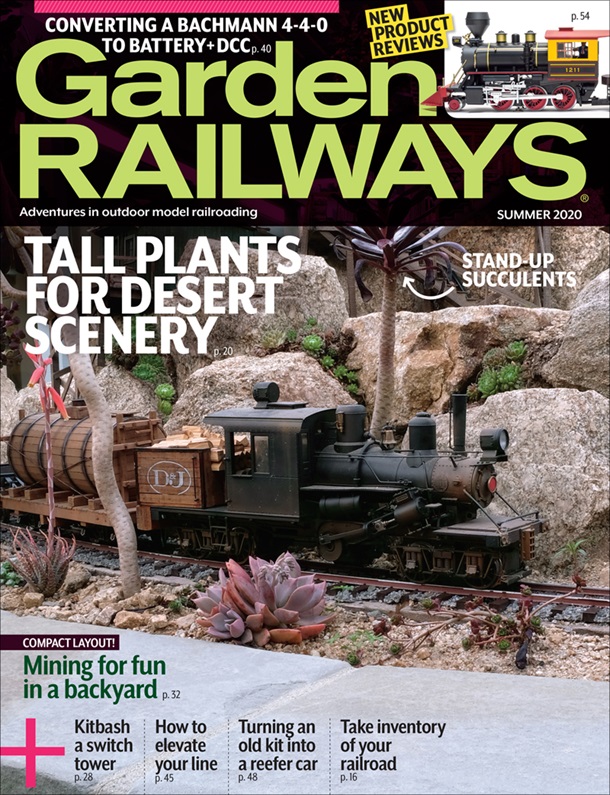

Wuhu Brand Arts & Crafts

Manufacturing Co.

Hongrui Machinery Park

High & New Technology

Development Zone

Wuhu, China

Price: $880, postpaid to the USA

Website: www.bowandeusa.com

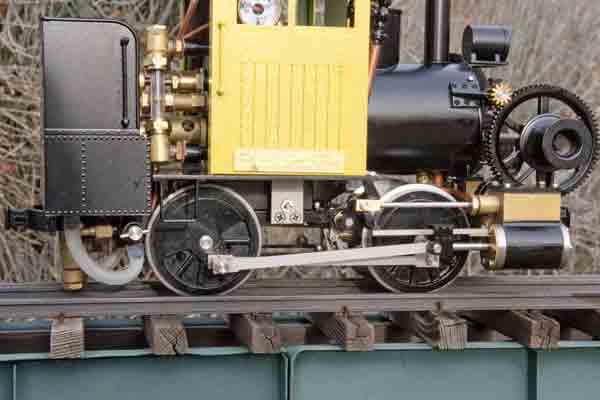

Gauge 1, 1:20.3-scale model of Falk logging locomotive in live steam; single flue, gas-fired boiler; pressure gauge; water glass, safety valve; throttle; water-filler plug; working whistle; water reservoir; axle pump with bypass valve; check valve; two, double acting, D-valve cylinders; Stephenson’s valve gear, controlled from the cab; displacement lubricator; sprung axles; dummy steam winch; all-metal construction; instruction booklet; also available in electric version ($450). Dimensions: Length overall, 8¾”; width, 4 1/8″; height over stack, 6 5/8″. In 1:20.3 scale, this works out to 14’9” x 7’0” x 11’3”, respectively

Pros: Good fidelity to prototype; good paint and finish; relatively high level of detail; easy fire lighting; lots of amenities; smooth running; relatively easy access to controls

Cons: Pressure gauge unreliable; speed difficult to control; access to gas jet (for cleaning, etc.) very difficult; smokebox door does not latch closed; water pump too low—fouls track

Wuhu, the builder of the model, is not well known to Americans, though they have been building British-style models for two or three years now. This engine is the company’s debut in the American market, according to their website.

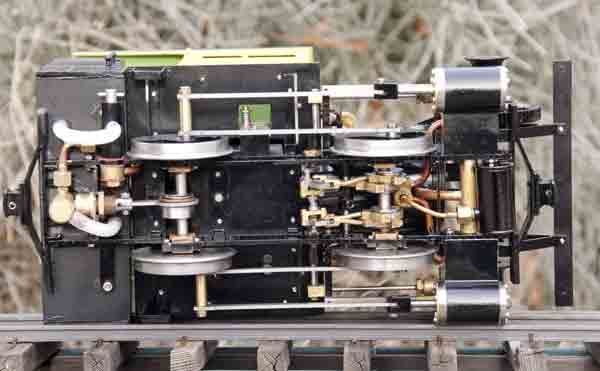

The model, being a replica of a small prototype, is likewise small but it is fully featured. Although the prototype is standard gauge, this narrow-gauge model appears to be an accurate representation of the prototype, based on photos that I was able to find. The single-flue boiler is gas fired, the gas tank residing on the footplate to the left of the boiler. Fittings include a water filler plug, a safety valve, a throttle, a water glass, an odd little pressure gauge, and a working whistle atop the steam dome, actuated by an attached lever. Because the water capacity in the boiler is limited by its size, the engine is fitted with an additional water reservoir in the back of the cab. Water is fed from this tank to the boiler through a check valve, by an axle pump fitted with a bypass valve.

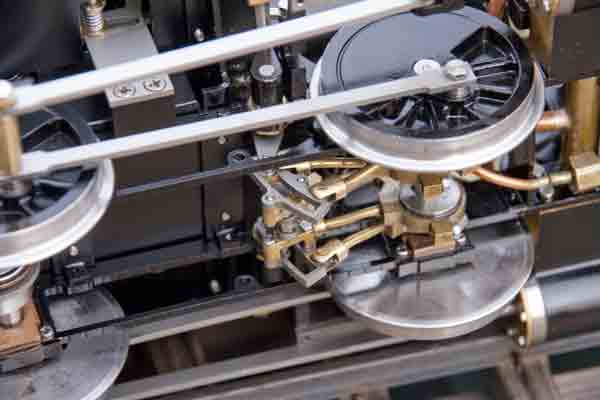

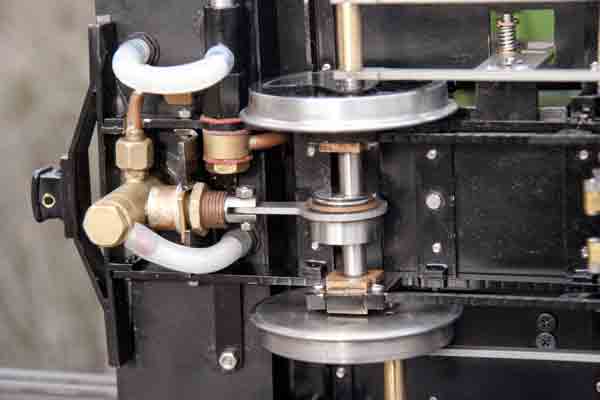

The engine has a pair of double acting, D-valve cylinders. A reversing lever in the cab controls the full, working, Stephenson’s valve gear between the frames. Motion is transferred outside the frames by rocker arms. A small dead-leg displacement lubricator is located between the frames at the front of the engine.

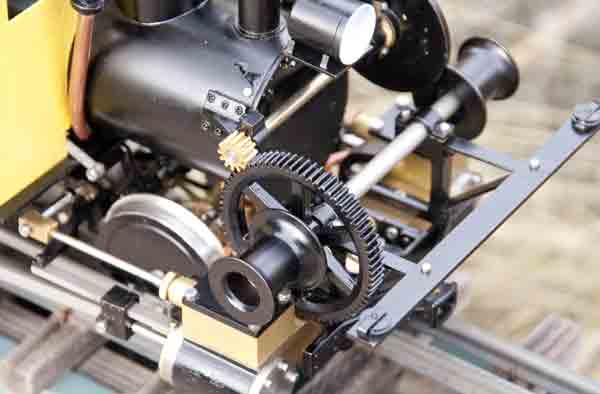

Also mounted to the front of the engine is the distinctive capstan winch. On the prototype, this is powered by a third steam cylinder in the cab. All of this gear is represented on the model but the steam cylinder is a dummy. However, the gears do operate and the winch can be turned manually.

The engine is painted black with a yellow cab. There is a large brass builder’s plate on the side of the cab. The dummy headlight is painted white inside. Link-and-pin couplers are furnished. An instruction booklet supplied with the engine contains color pictures showing the various features of the engine as well as rudimentary operating instructions.

I prepared the engine for operation in the usual way. All moving parts were first oiled with a lightweight machine oil. The displacement lubricator is a little difficult to access but I managed to get it filled with steam oil. It has no drain, so water must be sucked out the top at the end of the run or the beginning of the next. I filled the gas tank with butane using the usual adaptor, then filled the boiler with distilled water through the filler plug on the top. I also added water to the reservoir in the cab.

To light the engine, I opened the smokebox door, which is hinged horizontally halfway up. Interestingly, it has a latch on the outside that engages the winch shaft, keeping the door open for lighting. I turned on the gas and lit a match. The fire flashed back into the boiler immediately. In closing the smokebox door, I found there is no latch on the inside. The door just hangs there, a little open. This isn’t noticeable in operation.

I found this engine to be both interesting and challenging to run. Because the boiler is so small, pressure comes up pretty quickly. The instructions say to open the throttle when the pressure gauge reads 60-70 pounds. However, the safety valve lifted when the gauge read about 45 pounds. I later determined that the gauge was wildly inaccurate, to the point of being useless. I removed the safety valve and tested it, finding that it actually does release at around 65 psi.

I opened the throttle, helped the engine to clear the cylinders, and it was off—very fast—with the cylinders giving an audible and pleasing chuff. I found it difficult to control the engine’s speed. If it’s throttled down too far it will stall. I did find that giving it a load to haul helps. I also found that, after a lap or two, it needed to stop and catch its breath. The test day was pretty cool, with the ambient temperature in the lower 40s. I had the fire turned up fairly high to provide plenty of heat. At this setting, the burner was rather loud.

I put the engine into reverse, using the reversing lever in the cab. It ran well in reverse, too, until it came to a switch, at which point it jumped the track. It took me a minute to figure out that the pump body, at the rear of the engine, hung down too low and fouled the rail of the diverging track on the switch. When traveling forward, it made it across okay.

After several runs, the engine’s performance improved somewhat, and I was beginning to learn its habits. Because the boiler has so little room for water, the additional water supply is almost mandatory for a prolonged run. However, I found that, to keep up with demand, the bypass valve had to stay solidly closed all of the time. Even then, the water level in the boiler slowly dropped.

The whistle atop the steam dome is of the “peanut” variety. It’s a tiny thing, actuated manually by a spring-loaded lever attached directly to the whistle assembly. It does put out a nice, loud peep when the lever is depressed.

Some might say that running a new engine in the cold and wind is not a fair test, and perhaps it isn’t. With that it mind, I brought the engine indoors and set up a loop of track on the floor. After going through the same prep, I lit the fire and waited. In due course, steam pressure came up, I found that the whistle was a better indicator of boiler pressure than the pressure gauge.

With the engine on the track, I opened the throttle and gave it a little back-and-forth. When the cylinders had cleared, it set off with confidence. This time, there was no indication of shortness of breath and I could turn the fire down to a more comfortable level. Under these more controlled conditions, I also found the speed to be much more manageable. The engine easily delivered its advertised 20+ minutes of run, although the feedwater system still lagged a little.

This is not a locomotive that I would recommend to beginners. It is complex, fairly sophisticated, and has certain idiosyncrasies. However, if you’ve had some steam experience and are up for a challenge, this little engine can be a lot of fun.