Proxxon

2555 Tate Blvd. SE

Hickory NC 28601

Price: $109.80

Website: www.proxxon.com

Hot-wire foam cutter (Thermocut 115/E); 115V; adjustable wire tension; adjustable wire angle; built-in protractor; built-in angle gauge with fence; adjustable wire temperature; on/off switch; user’s manual. Dimensions: Base depth, 15 3/4″; overall depth, 20 1/2″; base width, 11 3/4″; base height, 3 3/4″; overarm height above table, 5 1/2″; throat depth from wire, 14″; wire diameter, .2mm (.0078″)

Pros: Extremely thin cutting wire; excellent guide system included; adjustable wire temperature for variable thicknesses and types of foam; wire can be angled for compound cuts; simple to use; easy precision cutting

Cons: Numbers on temperature-control knob a little difficult to read

Proxxon’s machine differs in some significant ways from other foam cutters I’ve seen. It is a benchtop model and, as such, has some size limitations. The effective thickness of foam that can be cut is around 51/2″. The throat depth is 14″. Given that, the machine is too small for massive sheets or blocks of foam. However, within these size limitations, it is stellar.

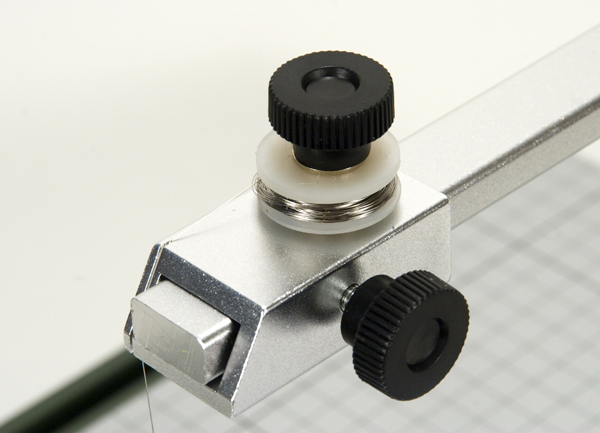

The cutter is supplied broken down in a box, with a complete user’s manual. Some simple assembly is required, thoroughly covered in the manual. The overarm must be put in place and the wire, which comes on a spool attached to the overarm, must be stretched, inserted into a hole in the base, and clamped into place. Be careful here, as the wire is springy and wants to unwind itself from the spool. Tension on the wire can be set by how much you spring the overarm when attaching the wire to the base. Once the cutting wire is in place and an electrical wire from the transformer is attached to the overarm under the base, the unit is pretty much ready to go.

An on/off switch supplies current to the wire. A knob next to that switch adjusts the heat of the wire. If the wire is too hot for the foam you are cutting, it will tend to cut unevenly. If it is too cool, cutting will be very slow or not at all. A chart on the side of the machine gives you a rough guide to the temperature setting based on the thickness (in millimeters) of your foam.

The cutting wire is the thinnest I’ve ever seen—just under .008.” It can be set up vertical to the base or at an angle. The latter is accomplished by sliding the wire-spool assembly back on the overarm until the desired angle is achieved.

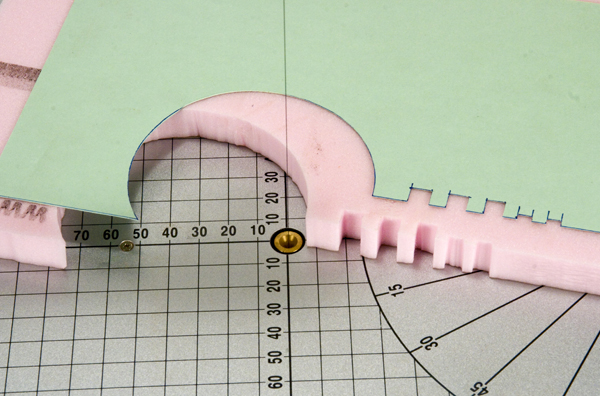

Printed on the table of the machine is a grid of 1cm squares and also a protractor at the front edge. Both of these can be useful in setting up auxiliary guides or just in freehand cutting the foam. Also supplied is an angle gauge that slides in a track, either along the front edge of the machine or along the left side. This guide can be set at any angle and it can also be locked to the base of the cutter. A 121/2″ aluminum fence is part of this guide. The fence slides in the guide and cannot be locked in place.

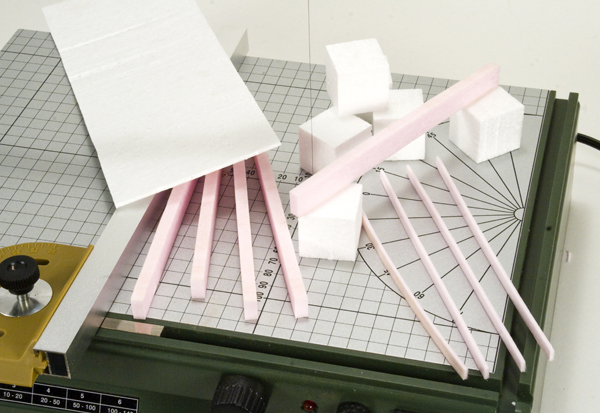

This is a fun machine to use. I tested the cutter with two types of foam—pink insulation foam and white polystyrene bead foam. With the wire set at precisely 90° (simple to do), I was easily able to cut thin slabs of foam of uniform thickness off a 5″-high block. If you crank the temperature setting all the way up, the wire will glow red, so watch those fingers! You can adjust the temperature setting even as you are cutting—the response is instantaneous.

With the Thermocut’s ultra-thin wire and excellent guide system, exceedingly precise work is possible. I had no difficulty in cutting as many pieces as I wanted of 1/16″ x 1/16″ foam “stripwood.” If you are building foam structures, any amount of highly ornamental work can be done by laminating different precisely cut foam layers to form a three-dimensional whole.

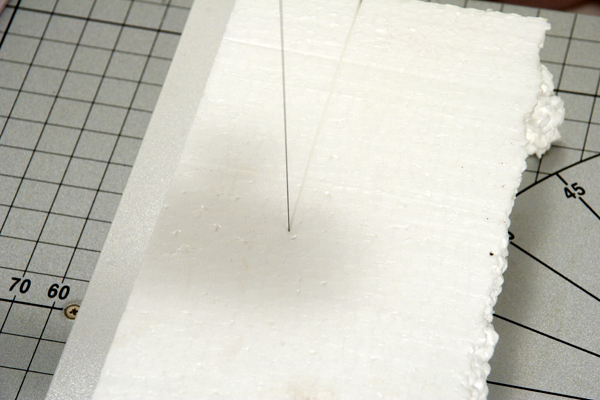

One thing I like is to use paper templates to make more precise or repetitive shapes. If you use a piece of light cardstock, like a file folder, you can draw a pattern or shape on it, then cut it out with an X-Acto knife. Tape or lightly glue the template to your piece of foam, then use the wire to follow the edge of the template. The wire will not burn or eat into the paper and surprisingly detailed shapes can be achieved this way. Also, if you are using the foam as a mold into which you are casting cement, this is a great way to provide additional detail to the mold.

Proxxon’s Thermocut hot-wire cutter is a robust and versatile machine. It is well thought out and designed and, within its physical parameters, is a tool that is limited only by the user’s imagination. Highly recommended.