Accucraft

33260 Central Ave

Union City CA 94587

Price: $1,156

Website: www.accucraft.com

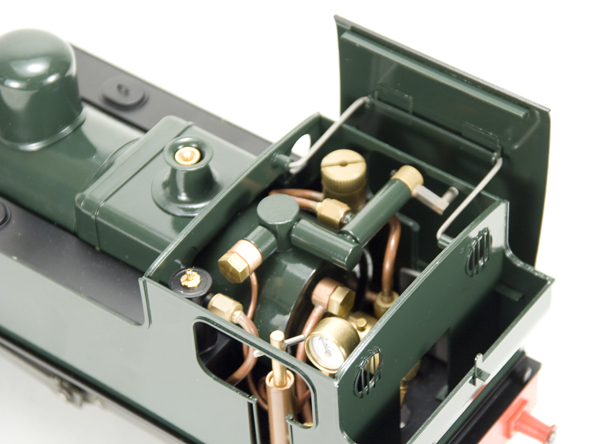

Gauge 1, 1:32 scale, live-steam model of a Victory-class 0-6-0T; all-metal construction; gas fired; single-flue boiler; two double acting, piston-valve cylinders; piston-valve reversing via a lever in the cab; all drivers flanged; displacement lubricator with drain; Goodall-type filler valve under dome; boiler blowdown valve; pressure gauge; gas reservoir in side tank. Dimensions: length over buffer beams, 10 9⁄/6″; width, 3 3/8″; height, 4 15/16″. In 1:32 scale, this works out to 28’2″ x 9’0″ x 13’2″, respectively

Pros: Clean lines; well made; excellent paint and finish; correct scale/gauge combination; working buffers; cab roof hinged to the side; improved smokebox-door latch; good running characteristics; good hauling capacity; quiet burner

Cons: No graphics; too-sensitive gas valve

Accucraft intends this locomotive to be a “starter” engine, which it is well designed to do. However, there is enough to it that it should appeal to more advanced steamers as well. It is a plain model of a plain prototype. The detail level is relatively low but, after viewing photos of the prototype, it is apparent that there are not a lot more details that could be added.

The engine is Accucraft’s typical gas fired, single-flue-boiler job. Fittings include a safety valve set to blow at 60 psi, a throttle, a 1/2″-diameter pressure gauge, a boiler blowdown valve under the left side of the cab, and a Goodall-type filler valve under the dome. A displacement lubricator stands near the right-hand door.

he engine comes with Accucraft’s usual tool kit—an assortment of wrenches, a couple of syringes for filling water and steam oil, and a special tool used to engage the reversing lever. This is a bonus, as the reversing lever is somewhat buried in the cab plumbing and is difficult to reach when the engine is hot.

Typically, Accucraft locomotives have a sort of spring-snap latch to keep the smokebox door closed. You push the door closed and the spring-latch secured it…usually. This often got out of adjustment and the door would not stay fully closed. This locomotive has a different smokebox-door latch—it’s magnetic. A tiny magnet built into the door engages another on a bracket inside the smokebox. The result is the door stays closed positively.

Body and paintwork are up to Accucraft’s usual high standards. However, there is no lining or other graphics or lettering, and no nameplate. These things can no doubt be added as the buyer wishes. The details that are there are nicely done, especially the handrails. The locomotive has a dummy Belpaire firebox.

The engine is fitted with outside cylinders and inside valves, giving the motion a clean look. Cylinders are controlled via piston valves. There is a single valve block between the frames, under the smokebox. Reversing is accomplished via a third piston valve, actuated by a lever in the cab. (The prototype no doubt had Stephenson’s valve gear.) This reverses the admission to and exhaust from the cylinders. This kind of reversing arrangement can only be done on a locomotive that has

piston-valve (or oscillating) cylinders.

Preparing this engine for running is slightly different from other engines. The lubricator is drained by opening the drain valve at the end of the previous run. This drains the lubricator of water and also of any remaining oil. The drain valve is effectively a blowdown valve. It is then left open while the engine cools, preventing a vacuum in the boiler. When ready to run again, the valve is closed and the lubricator refilled with steam oil. The gas tank is filled in the usual way. The valve is located near the pressure gauge on the right-hand side of the cab.

The boiler can be filled through the Goodall-type valve under the dome or by removing the valve and filling through the hole. The instructions say to open the water-level check valve below the left-hand cab floor (this is not a proper check valve, but a valve used to check the water level), then fill the boiler all the way up to the top. The fire can then be lit. As the water in the boiler expands and pressure builds, it will start coming out of the valve. When the water coming out has turned to steam, the water is at the proper level and the valve may be closed.

My first attempts at running this engine were not successful. The fire would not consistently stay lit. Also, I found the gas valve to be extremely sensitive, making optimal setting difficult. After multiple attempts, I adjusted the air-intake ring around the burner (a simple procedure), as Denver’s high altitude frequently affects gas-fired-locomotive operation. This solved the problem.

Following the instructions exactly, I was able to get quite a good performance out of the engine. I lit the fire and (as per instructions) left the smokebox door open for a couple of minutes. When I closed it, I had no trouble with the fire, although I did have to turn the gas down once or twice during the runs, as the gas tank, which is next to the boiler, tends to heat up. Using the “water-level check valve” to set the water level in the boiler, and filling the gas tank all the way, I was able to get a 13-minute run, the gas expiring before the water. This running time could likely be improved somewhat with practice. As with all steam locomotives, an experienced driver will always get the best performance. However, I felt that for a small locomotive, it did just fine.

The engine runs quite well. The throttle is a small lever in the right-hand cab door. It is conveniently accessible with the roof up or down. Despite the lever’s small size, the engine is easily controllable. With the supplied tool, the engine can also be reversed with relative ease. Given the locomotive’s weight, it should easily pull 20 or more four-wheeled British wagons. The burner is fairly quiet, as poker burners go, and the exhaust beats of the engine are clearly audible—nice.

At the end of the run I noticed that the magnetic door latch didn’t seem as snappy as it had before. I looked up neodymium magnets and found that, when heated above 176°F, they lose some of their magnetic qualities. If heated above 590°F, they are ruined entirely. I don’t know what the smokebox temperature on our engines gets to, but I’m sure it’s hotter than 176°. Something to think about.

This entry-level locomotive performed well—better each time I ran it. It’s easy to run, especially if the instructions are followed verbatim, and it’s easy to care for. It’s nice to see a reasonably priced, beginner-oriented engine in this scale. Most engines released in 1:32 scale in recent years are more complex (and expensive) machines. This one fills a gap and should bring the pleasures of live steam to many newcomers.