All of the 3D printer technologies that I am going to cover are considered to be an “additive” technology where material is added to make the part versus the “subtractive” technology where material is taken away. ( A good example of “subtractive” is machining metal with a CNC machine.)

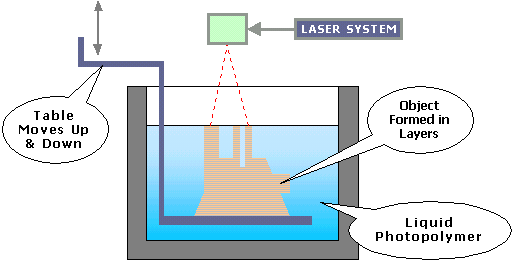

The difference between the two technologies is SLA uses a point laser (see drawing) and DLP uses a voxel data map. (Voxel is a fancy word for a small rectangular block.) The prices for this technology start at about $1,000 for the lower end models.

Dimensional Accuracy: ±0.5% (lower limit ±0.15mm/0.006”; but I have seen better: 0.001”)

Strengths: Smooth surface finish, fine feature details

Weaknesses: Brittle, not suitable for mechanical parts although I had some parts made using the SLA process with nylon and they are extremely strong.

I am looking at purchasing an SLA machine. It is a Formlabs Form 3, priced at $3,499.

Stereolithography (SLA)

SLA was covered in my last article, but I will quickly review the technology. An SLA printer uses mirrors with one positioned for the x-axis and one positioned for the y-axis. These mirrors aim a laser beam across a vat of resin, selectively curing and solidifying a cross-section of the object inside the build area. The object on the build plate is moved down farther into the vat, the photo sensitive material is screened over it and the process repeats. The disadvantage of this type of technology is that it can take a long time to trace the cross section of an object when compared to DLP.

The key difference between the SLA printer and the DLP printer is that DLP uses a digital light projector to flash a single image of each layer at once. Light is projected onto the resin using light emitting diode (LED) screens or a UV light source that is directed to the build object by a Digital Micro mirror Device (DMD) By printing an entire layer at once, DLP technology can deliver much faster print times than SLA.

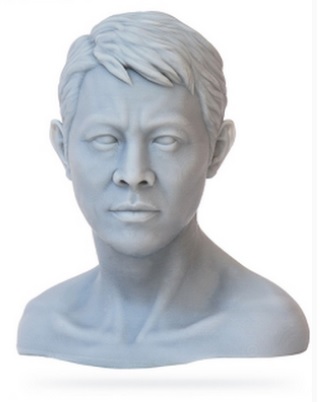

The pictures here show a DLP printer that is available from Matterhackers (matterhackers.com). The price for the SprintRay MoonRay S High Resolution DLP 3D printer is $4,430. They have two types of resins for this machine; one is a grey resin and the other is a castable resin for investment casting.

Powder Bed Fusion is a 3D printing process where a thermal energy source will selectively induce fusion between powder particles inside a build area to create a solid object. Some powder bed fusion machines can selectively apply color to the binding agent creating color parts.

Materials: Thermoplastic powder (Nylon 6, 11, 12)

Dimensional Accuracy: ±0.3% (lower limit ±0.3mm/0.012”)

Strengths: Functional parts, good mechanical properties, complex geometries

Weaknesses: Longer lead times, higher cost than FFF or FDM printers

Hewlett Packard makes a very good power bed printer with or without color capabilities. The HP Jet Fusion 300/500 printer is their lower end machines and the starting price is $50,000. However, companies like Xometry (xometry.com) can give you a quote on printing on one of their HP machines

Metal Powder Bed Fusion is a 3D printing process that produces solid objects, using a thermal source such as a laser or electron beam melting to induce fusion between metal powder particles. Similar to the power bed fusion described above, once a layer has been thermally fused, the powder is screened across the surface and the fusion takes place again and again until the object is built.

Materials: Aluminum, stainless steel, titanium

Dimensional Accuracy: ±0.1mm (0.004”)

Strengths: Strongest, functional parts, complex geometries

Weaknesses: Small build sizes, highest price point of all technologies

Xact Metal makes a metal printer, the XM200C. The build volume is 127 x 127 x 125mm (5 x 5 x 4.9”) and it is priced around $130,000.

The SLS process is not very difficult. First, a bin of polymer power is heated to a temperature just below the polymer’s melting point. Next, a recoating wiper deposits a very thin layer of the powdered material, typically 0.1mm thick onto the build platform. Now a CO2 laser beam begins to scan the surface. The laser will selectively sinter the powder and solidify a cross section of the object. Just like SLA, the laser is focused on to the correct location by a pair of mirrors. When the entire cross section is scanned, the build platform will move down one layer thickness in height. The recoating blade deposits a fresh layer of powder on top of the recently scanned layer, and the laser will again sinter the next cross section of the object onto the previously solidified cross sections. These steps will be repeated until the object is completed. Powder which has not been sintered remains in place to support the object. This eliminates the need for support structures.

Formlabs also makes a SLS printer. The build volume is limited to 165 x 165 x 320mm with a layer thickness of 100um (0.004”). The price is between $10,000 and $20,000, depending on the selected options.

Material jetting is a process where droplets of material are selectively deposited and cured on a build plate. Using photopolymers or wax droplets that cure when exposed to light, objects are built up one layer at a time.

Materials: Photopolymer resin (Standard, castable, transparent, high temperature)

Dimensional Accuracy: ±0.1mm/0.004”)

Strengths: Excellent surface finish, full color and multi material available

Weaknesses: Brittle, not suitable for mechanical parts, high cost

Material jetting works like a standard inkjet printer. The print head jets tiny droplets of photopolymer and then they are cured using an ultraviolet (UV) light. After one layer has been deposited and cured, the build platform is lowered down one layer thickness and the process is repeated until the object is built.

Material jetting prints large sections of the object in a rapid, line wise fashion. This is faster than many 3D printing technologies as other technologies use a point wide deposition of material. Thus, material jetting can produce parts at a more rapid pace than other types of 3D printers. Material jetting does require supports if the object requires them.

PROX DMP 300, from 3D Systems, is a material jetting printer. The maximum build size for this machine is 250 x 250 x 330mm. The price is greater than $250,000 depending on the options selected. Clearly out of my price range!

The printers discussed here are the next step up from FFF or FDM printers. Some printers are REALLY expensive and clearly not intended for the hobbyist. However, I wanted you to know about them because should you need a model that would use one of these technologies, there might be someone who, for a price, could make the object for you. Prices will certainly continue to come down and become more affordable to the hobbyist, but in the meantime, there are alternatives.