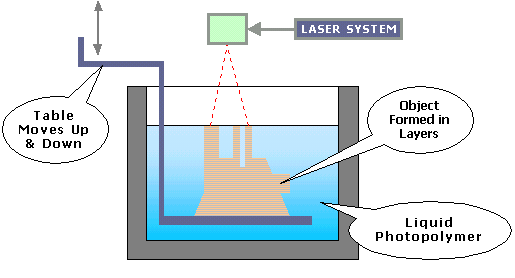

Stereolithography or SLA is known for its fine details and exactness. It uses a liquid photopolymer that, when hit by an ultraviolet laser, will harden. This is done layer by layer just like the FDM process except with layers about 0.025mm or 25microns. Much finer layers along with the exactness of the laser results in a part with very high resolution.

The figure to the right shows just one of the methods to process an SLA print.

Materials

There are many different types of resin materials to use with the SLA process. This process can produce plastic parts with high resolution, fine details, and a smooth surface finish. Given the three major classifications, a wide variety of resins are available for you to choose from. They are:

Standard resins – which are used for prototyping.

Engineering resins – which have specific mechanical and thermal properties from which to choose.

Castable resins – which can be used for high detail work just like lost wax.

Standard resins

The standard resins give high resolution prints with a smooth injection molding like finish. It is the most economical of all the resins.

Clear resins

Clear resins have optical properties that, with post-processing, can give it near transparency. It is much like the mechanical properties of the standard resins, but they can be brittle and have a low impact strength.

Tough resins

Tough resin is much like ABS–high tensile strength and high modulus of elasticity. It has excellent resistance to cyclic loads but is not recommended for parts with thin walls and is still brittle. It is not UV resistant, so the part must be post-processed to give it UV resistance.

Durable resins

Durable resins are a family of wear resistant resins with flexible mechanical properties. A durable resin should be used for parts that demand high flexibility, a smooth surface and low friction. As with tough resins, a thin wall is not recommended as the material has a low tension strength.

Flexible resins

Flexible resins are a family of materials that exhibit low tensile modulus (measure of the resistance to elastic deformation) that can be stretched. For example, you can make model vehicle tires, but it is not like true rubber because it does not exhibit all of the rubber properties. Flexible resins require support structures when printing, and they have a high UV resistance but are not suitable for thin walls.

Rigid resins

Rigid resins are reinforced with glass or other ceramic particles that makes the resultant part very stiff and rigid with a very smooth surface. This family of resins offer good thermal stability and heat resistance. They have a high modulus of elasticity (you can’t bend or stretch them) and under high temperature they will not deform however they are brittle. Rigid resins are also suitable for parts with thin walls and small features. Minimum wall thickness is about 100µm.

Castable resins

A castable resin enables parts to be printed with sharp details and a smooth finish. In the lost wax process it will burn out cleanly without leaving ashes or reside. Castable resins would be a good choice for parts with printing on them that require a metal to sustain them through the environment. I am thinking about Bettendorf trucks.

I do not yet own an SLA printer so I will have to find someone to print these parts.. I just happened to be at the Del Mar Electronics show this year and ran into several companies that could do the job. After much discussion at the show and later via phone and emails I decided that ULTIMATE3D (ult3.com), Hillsboro, OR., would make the parts for me. They will use a Projet 3500 printer. This is not an inexpensive printer. You would have to make the decision to buy a new car or buy one of these printers. The material that they will be using is Visijet M3-X, ABS like opaque white. From the 3D systems website I was able to find out the following:

The VisiJet® M3-X is a stiff, ABS-like material with the look, feel and performance of injection molded plastic. It produces tough parts with a stunning white finish and high temperature resistance, making it ideal for product mockups, prototyping, and rapid tooling applications.

Now that I have identified the vendor and am satisfied with the material, it is time to have them print the parts out. I have three different parts and I want 10 of each. Total cost is about $200.

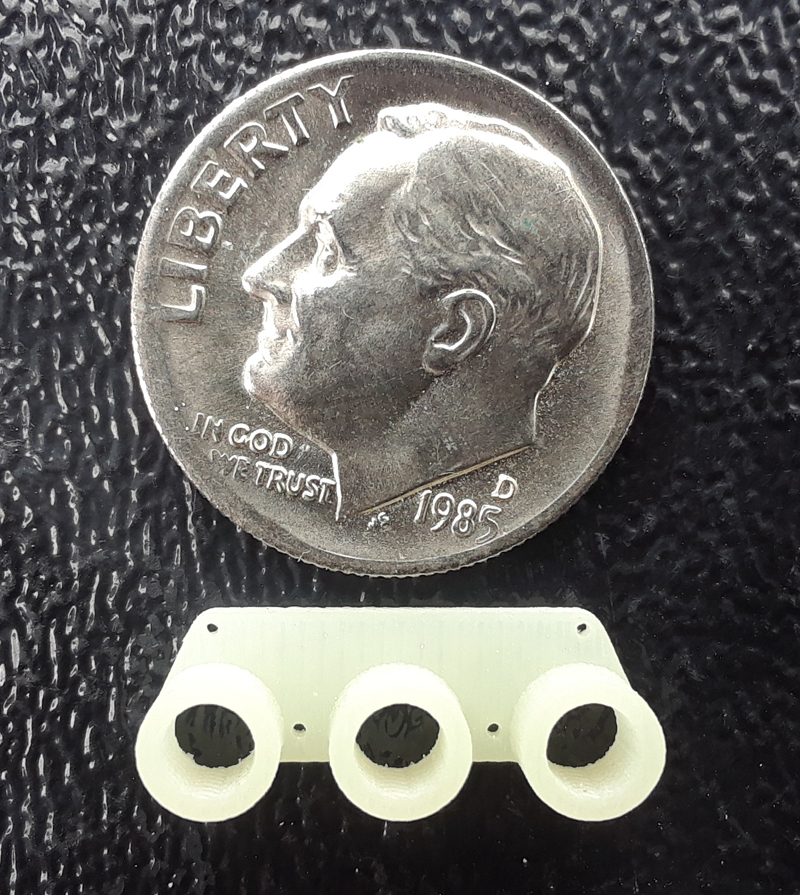

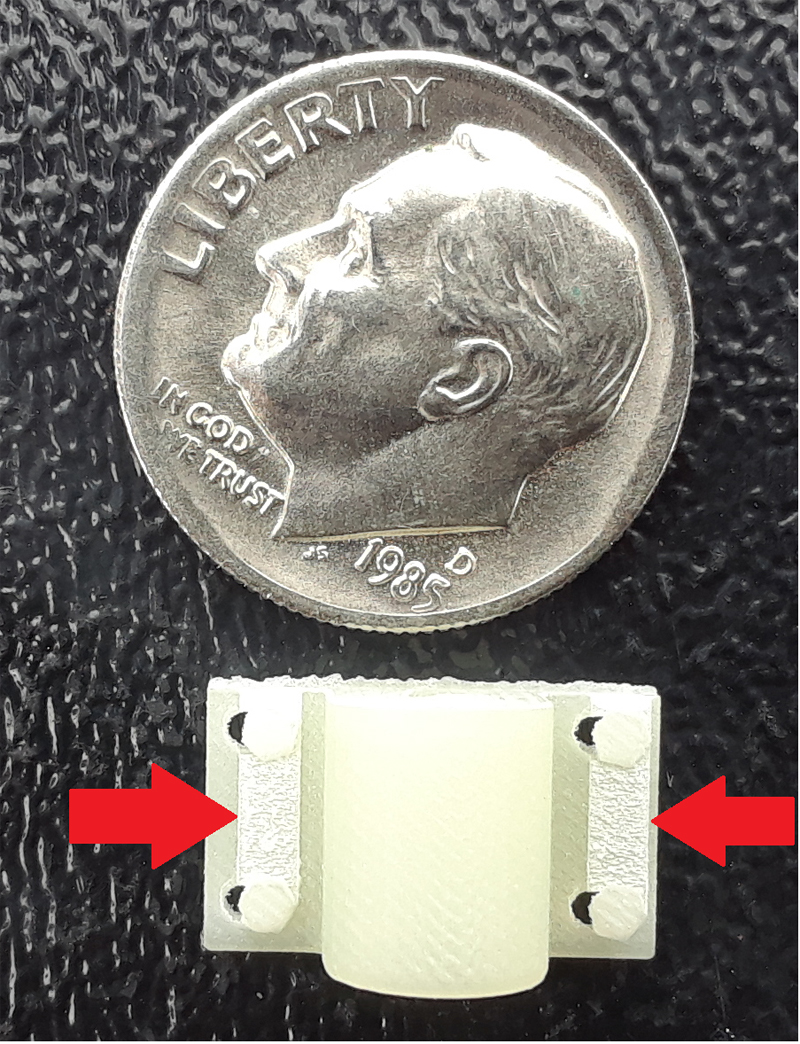

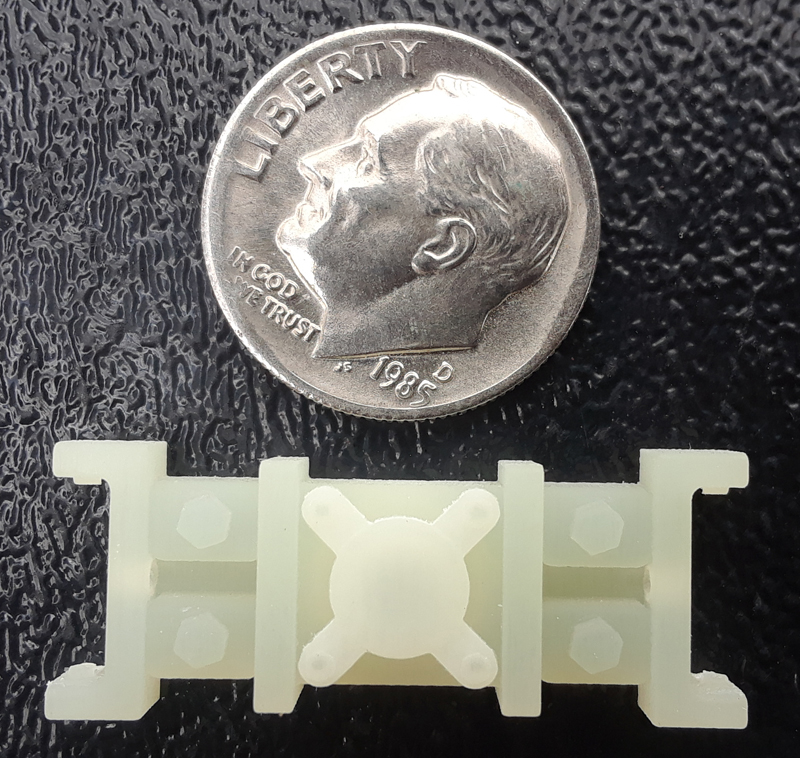

Here are photographs of the finished parts as they came from the vendor. You can see the high detail and the resolution of the parts.

You can see the extremely high resolution of the part. Look at the very small holes and see how well they came out. There is a little roughness in the shaft holes, but they are so small I am not going to worry about it. BIG difference between the part I printed out using the FDM process and the SLA process. Looks like I am going to have to forgo a new car for a while!

On the part in photo 2 you can see some roughness as well. You will notice on the left and right sides there are some of what we call “abstracts”. These are shown by the red arrows. They were not in the plan but I was warned that the printer computer might try and fill these in. (You know, just trying to help.) They are supposed to be elongated holes but the way the software looks at it these portions of the elongated hole are supposed to be filled in. Fortunately, they are not high off of the surface and can be easily removed.

The part in photo 3 is as perfect as it gets. There is a hole in the back of this part and the 3mm bearing drops right in with just enough snugness. The bold heads came out perfect.

SLA printers where introduced in this article, and some of the benefits and drawbacks with this type of printer have been presented. SLA printers are expensive, a challenge to maintain and should not be your first printer. With experience and absorbing the cost of the current SLA technology, very high resolution prints can be made. This technology also has the benefit of many different types of resins being available for different applications like very flexible parts to printing parts for something like a lost wax process.