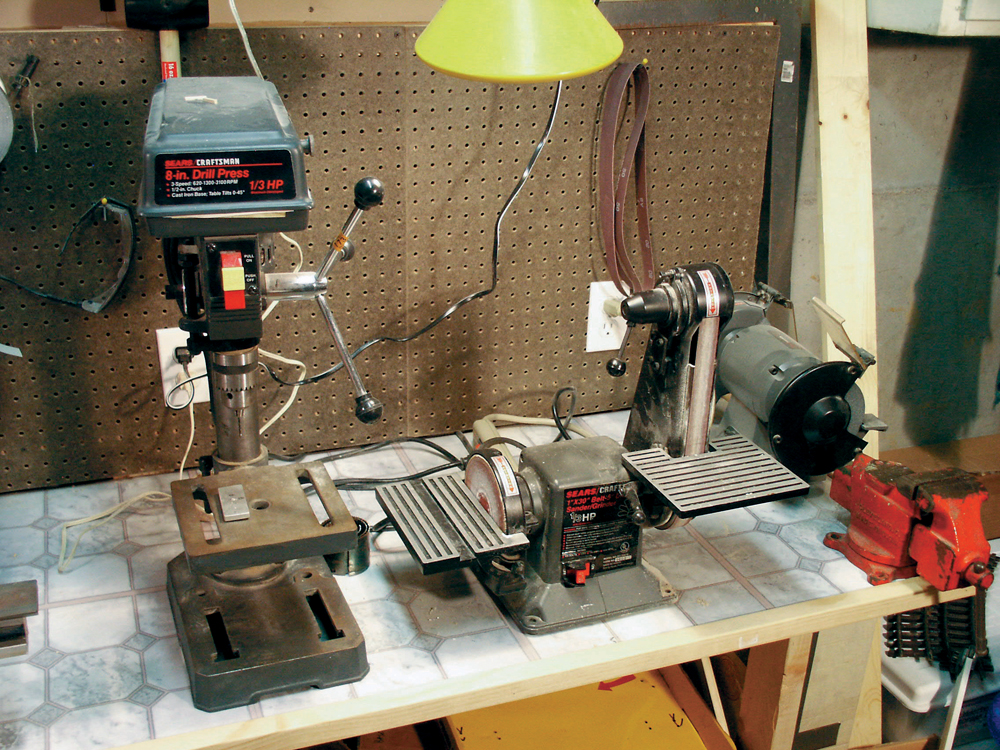

Garden railroad workshops come in all shapes and sizes. What is important about the workshop is that the work surface be large enough to accommodate whatever it is you want to work on without knocking into your stash of tools, paint and glue bottles, or anything else. Make sure your workbench is sturdy.

The height of the work surface is also an important aspect to consider. Do you prefer to work standing or sitting? Some tasks, like cutting, drilling, and sanding are better done standing, while painting and building are best done sitting. Benchtop tools may have to sit on sturdy boxes or risers to elevate them to a comfortable working position if the work surface is at regular desk height.

Storage is an important part of design and organization. Every tool needs a place, and that place should be easily accessible from wherever it is that tool will be used most often. Storing commonly used tools on a wall away from the workbench will not work well, as the effort required to get out of the chair and walk over to the wall to return the tool, once finished, will be far greater than that required to simply sit the tool on the workbench. The tool will then get buried, lost, or will otherwise disappear into a parallel universe. Having the tool’s “official” place within arm’s reach of your seat will minimize its tendency to play hide-and-seek.

A good workbench needs to be well lit. Each task area should have its own adjustable light. It’s so much easier to work when you can see what you’re working on. I use full-spectrum bulbs in my lamps. They’re more expensive, but it’s nice to have a light source that approaches the “color” of full sunlight, especially when painting.

Basic tools

small, rotary hand tool should be on any workbench. An adjustable chuck (shown) is more desirable than a standard collet, as this allows bits of any size to be used with the tool. Photo by Kevin Strong

A good collection of small hand tools, such as pliers, diagonal cutters, and screwdrivers, are essential items to have on hand. Other small hand tools should round out your basic toolbox. These include a couple of X-acto knives. A razor saw is another useful tool. A set of both large and small files will come in handy for shaping building materials. A good supply of clamps, large and small, is great to have on hand as well.

A Dremel or other rotary hand tool is probably the most commonly used tool on my workbench. The reinforced cutting wheels are great for cutting a variety of materials. Regardless of whatever brand you use, find one with an adjustable chuck.

Disk/belt sanders are great for cleaning up the ends of cut lumber, sanding multiple pieces of lumber to the same length, or any other instance where you need to sand things.

Drill press. A drill press is great for setting up jigs for repetitious drilling tasks, or even for embossing rivets into brass or styrene sheets.

Bandsaw. There’s almost nothing you can’t cut with a bandsaw. A good, variable-speed bandsaw will provide great service. They can handle light metal, as well as wood and plastic, with relative ease. The key measurement in a bandsaw is the throat clearance, or the distance between the cutting blade and the housing at the left that protects the blade (or you from it) as it continues around. Most benchtop models have either a 9″ or 10″ clearance.

Benchtop vise. The vise should be mounted on a sturdy part of the workbench, as it will be taking considerable abuse through the course of its life.

Of all the tools in the workshop, two are by far the most important and haven’t been mentioned yet. They are your eyes and hands. Everything else in a workshop can be replaced if it breaks. Eyes and hands don’t come with warranties, so take the necessary precautions to protect them.