A house, a car, and a layout all have something in common: they turn out better when they’re built on a solid framework. This is especially true of a helix. A helix – a spiral ramp meant to lift a model train from one level of a layout to another – may not be prototypical, […]

Read More…

Open-grid benchworkStarter layouts are often flat and built on a 4 x 8 sheet of plywood. However, the majority of layouts have tracks at varying heights separated by grades. The easiest way to add elevation to a layout is to use open-grid benchwork. For this type of construction you place a plywood subroadbed under the […]

Read More…

How to wire power-routing turnouts: While it may initially seem difficult, basic two-rail wiring for power-routing turnouts is easy if you understand and apply just two simple rules. The diagrams below demonstrate these crucial wiring principles. Rule 1: Gap the rails between turnouts located frog-to-frog. Place gaps in both rails, between turnout frogs in opposite […]

Read More…

Start watching this project model railroad video series 4 weeks to a bigger layout: Benchwork 4 weeks to a bigger layout: Roadbed and track 4 weeks to a bigger layout: Scenery 4 weeks to a bigger layout:Ballast 4 weeks to a bigger layout: Structures 4 weeks to a bigger layout: Operations […]

Read More…

Instead of using spikes or contact cement, Model Railroader contributor Chuck Hitchcock shows you how to use DAP adhesive caulk and topper tape (a material used to insulate pickup truck caps) to lay track. Quick and easy Flextrack […]

Read More…

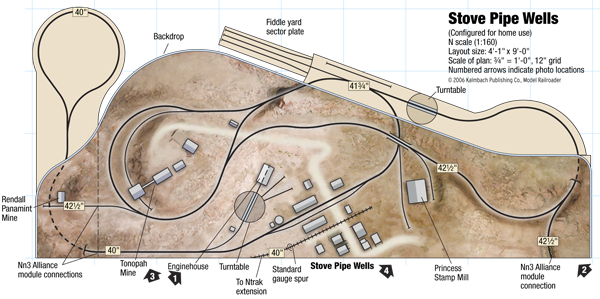

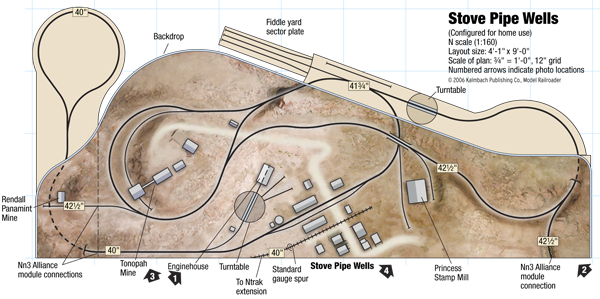

Track plan at a glance Name: Stove Pipe WellsScale: N (1:160) narrow gauge (Nn3)Size: 4′-1″ x 9′-0″Theme: mining short lineEra: 1870s to 1950s, depending upon rolling stock usedStyle: portableMainline run: 34′-6″Minimum radius: 10″Minimum turnout: no. 5Maximum grade: 5 percentOriginally appeared in the December 2006 issue of Model Railroader.Also appeared in 102 Realistic Track Plans.Click on […]

Read More…

Align every rail joint Every rail joint must be carefully aligned, properly fitted, and level. Sight along the rail to check the alignment through the rail joiner. After the track is spiked down, use a fine file to smooth the top and inside corner of the rail joint until you can slide a fingernail across […]

Read More…