CHICAGO— The questions “what took so long?” and “when will the others be operational?” weren’t entirely answered Thursday, Oct. 23, when Trains was among those invited to observe, along with Amtrak president Roger Harris, the workings of the long-overdue train wash located near the south end of the company’s 16th Street coach yard.

“Each one of these facilities has to be individually engineered, and any time you are using federal funds there is a lengthy process you have to go through,” Harris says. “There’s always the complexities of priorities and funding. We haven’t had an operable car wash here for a long time, and coming into the yard this morning it was really impressive to see the sparkling fleet — cleanliness of the trains is something to be proud of.”

As he is talking, inbound Floridian equipment was beginning to dry off as it slowly emerged from the washer. The train had arrived from Miami 25 minutes early that morning — no, Harris was not aboard — and was slotted between two state-owned Venture trainsets: the Pere Marquette from Grand Rapids, Mich., and a Lincoln Service set off train No. 300.

“A little fast — 2.1 miles per hour,” says Pat Esposito. He is the manager from contractor John Burge Construction, the company that engineered and built the $6.3 million replacement for an aging predecessor in the same structure. Amtrak terminal road foreman John Sloan says that equipment “was just shooting water with brushes worn down, not even touching the sides of the cars” before it was decommissioned several years ago.

Earlier, Esposito explained that wash speeds at or slightly below 2 mph are optimal. Trains backing in from the south end pass through an arch spraying acid, which is then washed off by automatically-activated brushes and high pressure sprayers blasting reverse-osmosis water purified to remove contaminants. This helps deliver a spot-free finish on windows. Recycling the resulting wastewater reduces the demand for fresh water.

“It’s a closed system that recirculates the water,” says Esposito. An array of high-powered blowers are affixed to an arch near the south end of the building to help expedite drying as the train pulls out. Also new: five large exhaust fans and vents to actively remove diesel smoke; the previous facility only had open, passive roof vents.

Meanwhile, the acid runoff that occurs early in the process flows into a tank to be neutralized and sent to a pollution control building. The tank fills up after about 40 cars and locomotives pass through. The parade of trains must occasionally pause to accommodate the five to 10 minutes needed to empty the neutralizing tank.

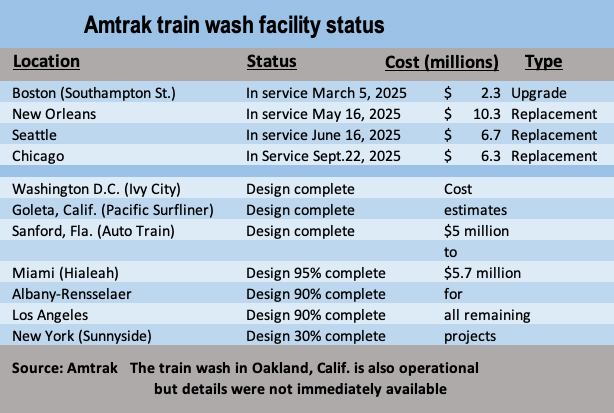

Standardized design and components are being implemented at the seven additional sites where train wash facilities are continuing to undergo upgrading or full replacement. This is meant to ensure consistency, reliability, and ease of maintenance. Amtrak’s Harris says he learned that the train wash at Amtrak’s relatively new Oakland (Calif.) Maintenance Facility is again operational, though it was not included on the list of projects completed or underway.

After the Lincoln Service set emerged, Harris noticed that the windows and upper side of a Venture business class coach appeared to be spotless, but grime remained below, where the carbody pinches inward at floor level. This design permits the cars to be used on the Northeast Corridor, with its reduced horizontal clearances. The ground-in dirt — perhaps from years of not getting washed — didn’t appear below the window line on the other cars. The aberration was duly noted, and all seemed to agree that brushes needed adjustment.

To bad it doesn’t work on the interiors.

Amtrak is finally decided to fix the wash facility at Union Station. Nobody wants a dirty car on any Amtrak train.

I see the Texas Eagle pass through Temple, TX several times a week. That the cars are being washed is evident. Unfortunately, squeaky clean equipment does not seem to have done anything for the Eagles late running. Over the last week it has been late by nearly an hour every day.

Wonder if it can be used during the winter months, when it’s needed the most.

Great that Amtrak has finally decided to wash its trains. Hopefully they’ll properly maintain the wash racks in the future. It’s nice to be able to see out the windows.

CHRIS— Hopefully you’re not old enough to remember Amtrak’s Lexan windows which got worse with every car wash. I remember two trips (Chicago to Champaign 1974 and Detroit to Buffalo 1975) where I couldn’t see out the window. Which actually made the ride on the bumpy ICRR even more unsettling.

Charles, I actually never road Amtrak until the late 70s although I did ride the L&N several times between Mobile and New Orleans in the 60s. Never saw any Lexan but I’m sure it didn’t hold up to the harsh railroad environment. Hard to understand how Amtrak has quite often forgotten that part of traveling by train is enjoying the scenery. Hopefully they’ll keep the trains and windows clean and never go back to the Lexan glazing days.

Charles, I actually never road Amtrak until the late 70s although I did ride the L&N several times between Mobile and New Orleans in the 60s. Never saw any Lexan but I’m sure it didn’t hold up to the harsh railroad environment. Hard to understand how Amtrak has quite often forgotten that part of traveling by train is enjoying the scenery. Hopefully they’ll keep the trains and windows clean and never go back to the Lexan glazing days.