WASHINGTON — The National Transportation Safety Board has called for on-track rail maintenance equipment to be equipped with collision avoidance technology that can detect people or objects prior to a crash.

The recommendation came as part of the final investigation report released today (Sept. 3, 2025) on an Aug. 4, 2023, accident in Great Barrington, Mass., where a Middlesex Corp. maintenance machine struck and killed a worker. [See “Victim identified in death at Massachusetts track project,” Trains.com, Aug. 26, 2023]. The NTSB investigation found that the operator of the drilling machine had no safety devices beyond a wide-angle mirror to look for hazards.

The call for collision avoidance technology was directed at the Federal Railroad Administration, all Class I railroads, and the two entities involved in this incident (the Housatonic Railroad Co. and Middlesex Corp. The report also calls on the FRA and Class I railroads to require that maintenance machinery with booms or other extensions to be equipment with a people detection system covering the length of the boom or extension; and requests that the American Short Line and Regional Railroad Asosciation and the National Railroad Construction and Maintenance Association inform their members of the benefits of collision avoidance systems, as well as informing employees of the circumstances of this incident and the need for thorough job briefings.

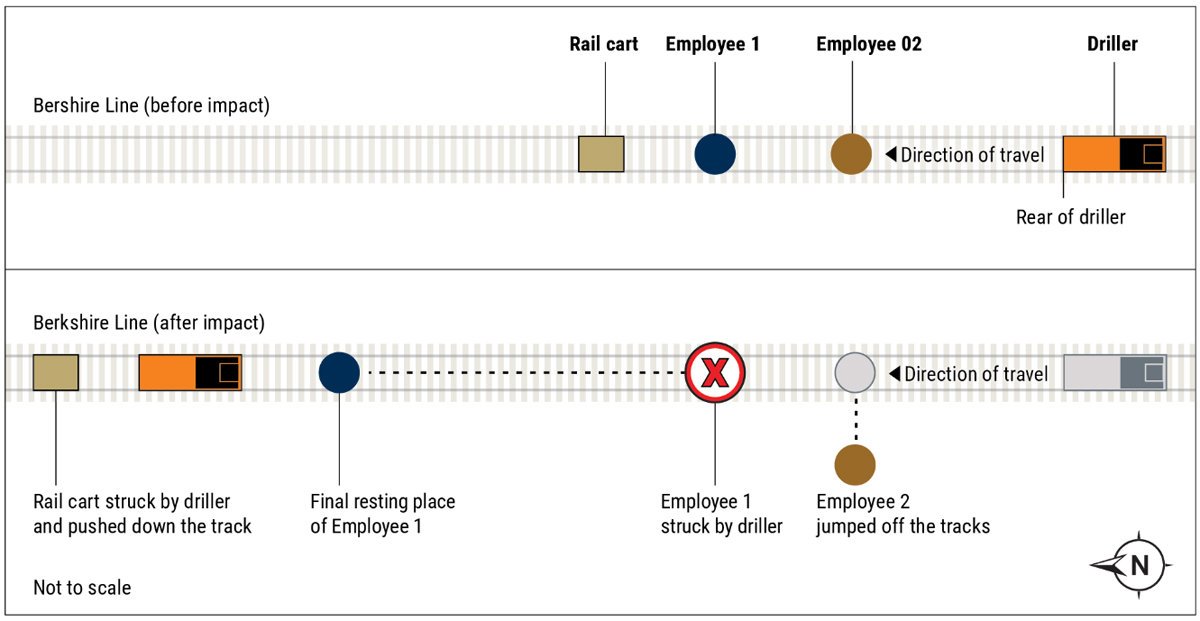

The incident occurred when a tie-drilling machine was returning to the site of track work after being removed for repairs. During a 1.4-mile backup move to the job site, the driller operator did not see two employees who had continued to work at the job site and were on the track as the tie driller; one of those workers was struck and killed.

The accident report concluded that the probable cause of the incident was the driller operator’s failure to observe that the path of travel was clear. Contributing factors, the report says, were a lack of awareness of job tasks on the part of the Housatonic Railroad Co.’s worker in charge, which led to an inadequate job briefing; that worker’s lack of awareness of maintenance-machinery movements without his knowledge or authorization; the lack of a required second worker in charge for a second work group, and a lack of communications between the worker in charge and the second work group.

Laudable recommendation… But does that type of technology even exist?

Maybe before calling for something that isn’t available, the NTSB should call for the creation of such technology, what it would consist of and how it work work. Detecting a piece of solid equipment could be done in many ways. But detecting a person might be very difficult unless it was some kind of proximity beeper or beacon. In the end, the best avoidance technology may still be human beings standing close by with a radio in their hand. Or is that TOO SIMPLE?

What happened to red flag and blue flag protection? If you have people on the tracks you need to flag this accident should have been avoided. The railroads need to teach work zone safety instead of counting money.