ATLANTA — When a broken wheel caused a derailment on Norfolk Southern — just a mile after NS received the train through interchange — it prompted the railroad to begin tinkering with new ways to detect wheel defects.

“We as a leadership team said there’s got to be a better way,” Chief Operating Officer John Orr said on the railroad’s earnings call in October.

What emerged is the railroad’s wheel integrity detection system, which NS built in conjunction with the Georgia Tech Research Institute. The first wheel integrity detector was installed recently on the Chicago Line at Burns Harbor, Ind., part of the railroad’s busiest route.

“The location allows NS to inspect trains coming onto its network as soon as possible,” spokeswoman Heather Garcia says.

The technology builds on NS’s homebuilt Digital Train Inspection portals, which use AI-powered imaging systems to scan trains at track speed and identify a range of mechanical defects. Since early 2025, these portals have flagged more than 40 wheel integrity issues that could have led to derailments.

The new detector system takes inspection a step further. Focused solely on wheels, it uses six synchronized cameras (three per side) to capture up to 14 ultra–high-resolution images per wheel as trains pass at up to 70 mph. Advanced AI algorithms then analyze those images.

Thanks to optimized camera angles and lighting, the system can tell the difference between grease, dirt, water, and actual cracks — dramatically reducing false positives and improving early detection.

“Rapid deployment of next-level field technology is part of a broader strategy to transform inspection, reliability, and overall performance,” Orr says. “We’re advancing machine vision at speed across our network.”

The project brought together NS teams from Digital & Technology, Mechanical, Communication & Signals, Operations, and the Network Operations Center, with AI algorithms and infrastructure developed internally and integration support from Georgia Tech.

“That ability to take ideas, understand the business, convert them into actionable items, and then put them into field use at scale is a testament to the commitment we’ve got on safety,” Orr says.

After testing wraps up at Burns Harbor, NS plans to expand the system at several additional locations next year.

NS installed its eighth Digital Train Inspection portal in the third quarter. The portals also have been catching wheel defects.

“We positively identified over 40 wheel integrity defects and we’ve launched six new algorithms with nine more already in development,” Orr says. “The data from these field technologies feed our war rooms that are staffed with craft employees, managers, and senior executives, facilitating real time problem-solving and cross-functional collaboration.”

Two questions on this gadget. How expensive to build, and how expensive to maintain? Given the cost of a derailment’s loco, car, track and surrounding real estate damage, plus insurance costs, may be very worthwhile.

Excellent questions! I’m assuming the NS thought that the cost/benefit ration was sufficiently high to make the research worth doing. This would also be a positive answer to questions on what NS is doing to improve safety.

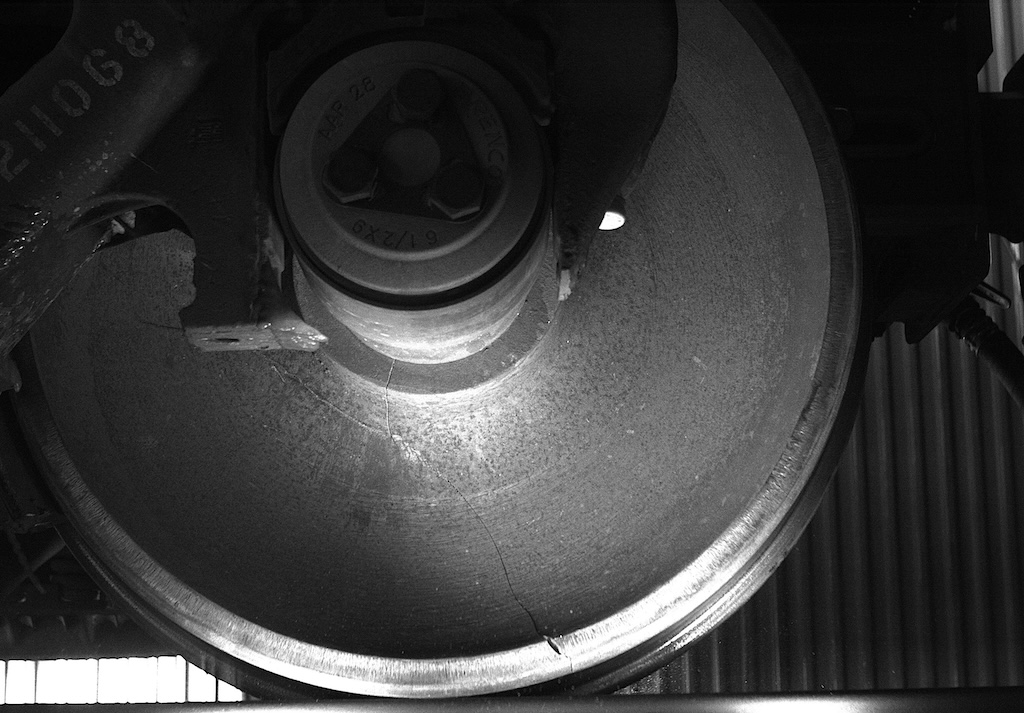

After looking at that wheel picture, I’ve got one word: WOW!