Having trouble viewing this video? Please visit our Video FAQ page Model Railroader Senior Editor Jim Hediger has had a long and impressive career at the magazine. In this video interview Jim shares his experiences about first coming to work for Model Railroader, including meeting the magazine’s then-Editor Linn Westcott. Subscribe today and watch […]

Subscription: Subscription - Digital

Video: History according to Hediger 2

Having trouble viewing this video? Please visit our Video FAQ page Model Railroader Senior Editor Jim Hediger has had many experiences working with the real railroads. In this episode he talks about how he acquired his collection of official paint chips from the Detroit, Toledo & Ironton RR, as well as how the DT&I […]

Four generations of train lovers

[…]

Four generations of train lovers

[…]

How-to Library: Building a turntable, Part 6 – A-frames, gallows, and truss rods

David’s pile of parts is much smaller, as he works to complete the O scale laser-cut wood turntable kit. In this episode, he’ll share his insights for working with basswood stock and bending metal rods. Next and final steps? Adding the finishing details! […]

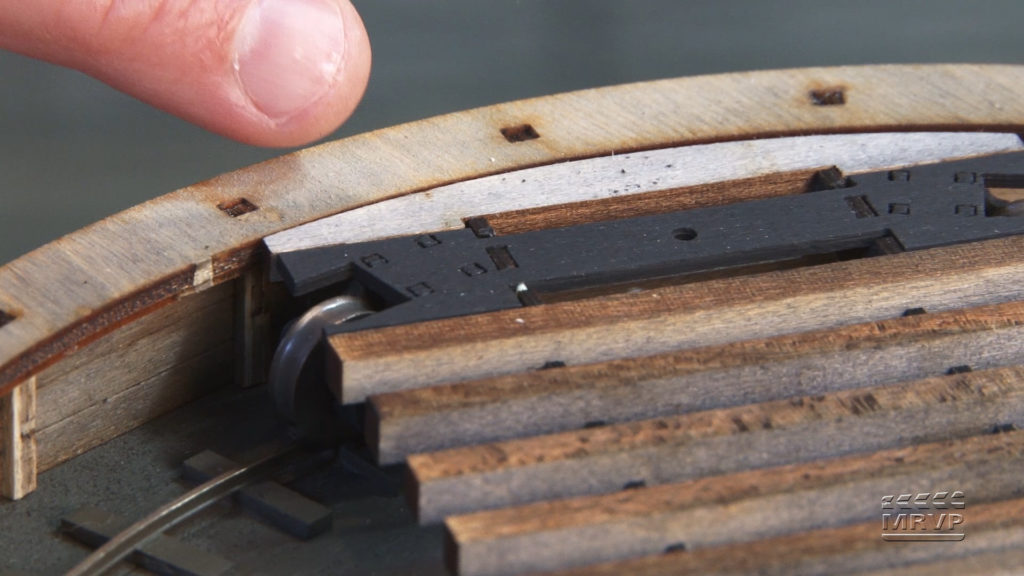

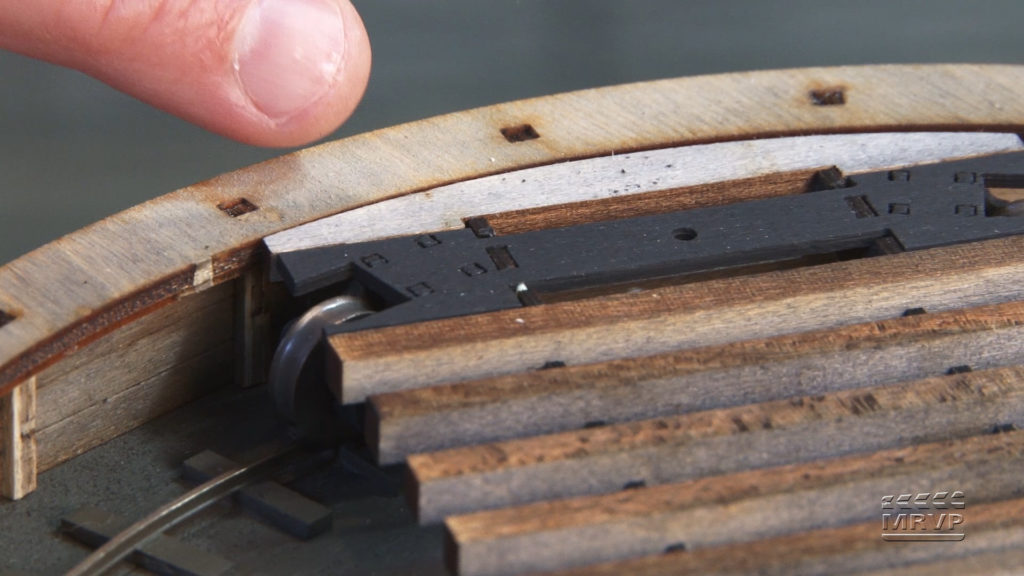

How-to Library: Building a turntable, Part 5 – Wheels and track installation

The bridge assembly is well underway, so David can now focus on building and installing the wheels that put his O scale laser-cut wood turntable kit into motion. If that’s not enough, he even gets the rails placed on bridge deck and takes a locomotive for a spin! […]

How-to Library: Building a turntable, Part 5 – Wheels and track installation

The bridge assembly is well underway, so David can now focus on building and installing the wheels that put his O scale laser-cut wood turntable kit into motion. If that’s not enough, he even gets the rails placed on bridge deck and takes a locomotive for a spin! […]

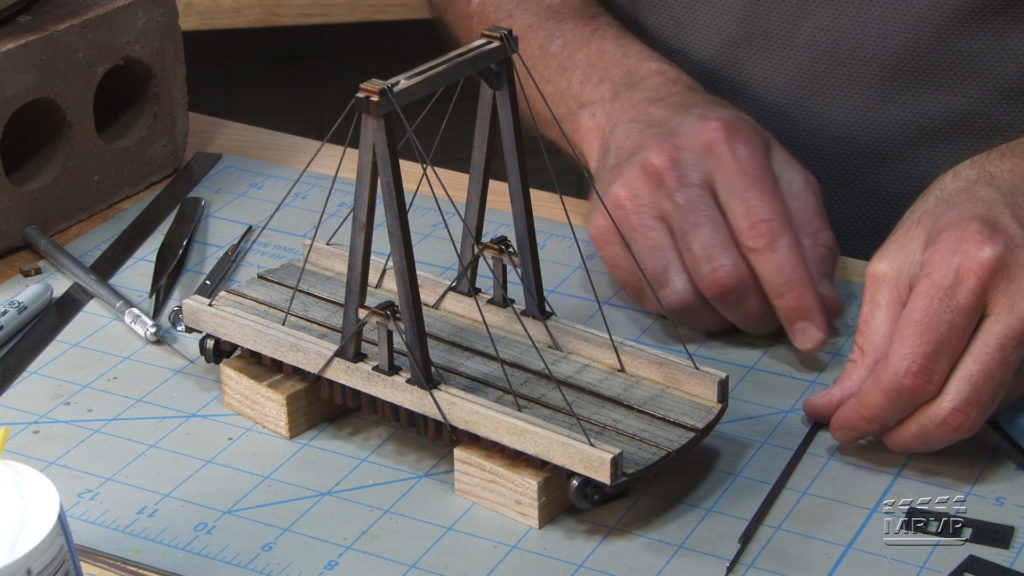

How-to Library: Building a turntable, Part 4 – Bridge parts assembly

After installing the motor mechanism, David adds an automated polarity control to his O scale laser-cut wood turntable kit. And then, it’s on to separating, sorting, and building the bridge assembly. […]

How-to Library: Building a turntable, Part 4 – Bridge parts assembly

After installing the motor mechanism, David adds an automated polarity control to his O scale laser-cut wood turntable kit. And then, it’s on to separating, sorting, and building the bridge assembly. […]

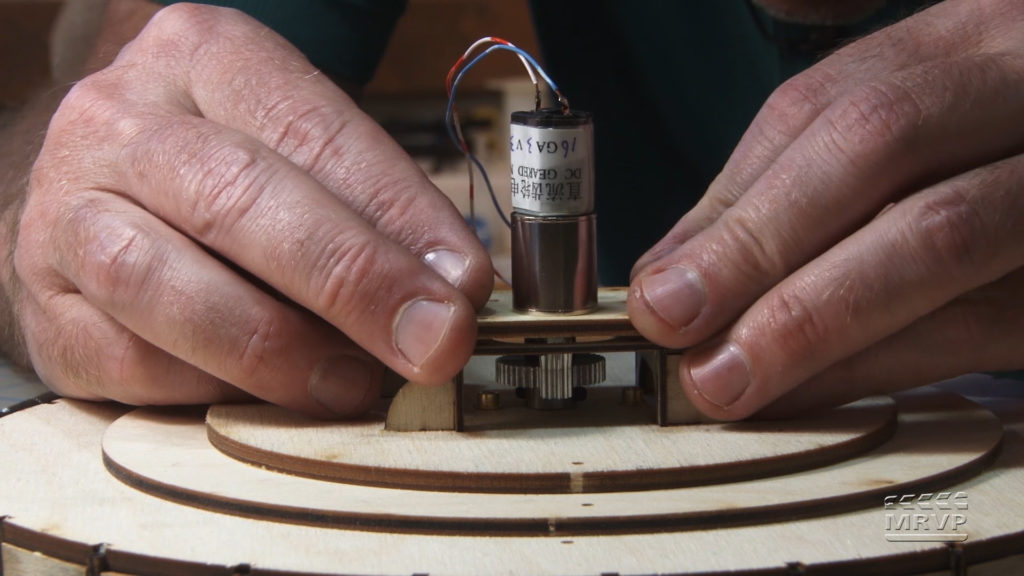

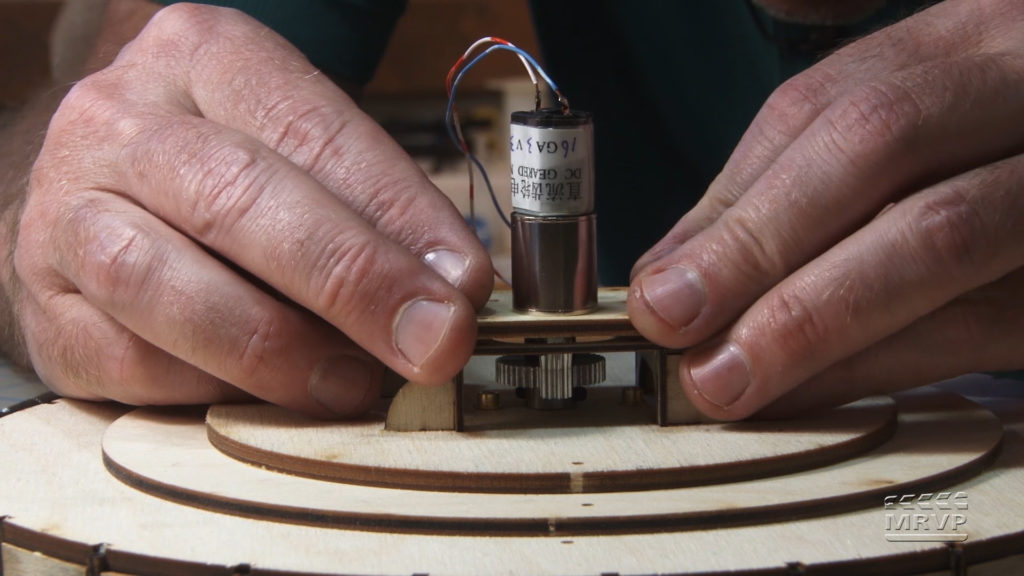

How-to Library: Building a turntable, Part 3 – Installing the motor mechanism

David has now arrived at the stage where it’s time to install the drive mechanism into his assembled O scale laser-cut wood turntable kit. Follow along as he shares his process for fitting the 3-volt can motor and reduction gear used to put the structure into motion. […]

How-to Library: Building a turntable, Part 3 – Installing the motor mechanism

David has now arrived at the stage where it’s time to install the drive mechanism into his assembled O scale laser-cut wood turntable kit. Follow along as he shares his process for fitting the 3-volt can motor and reduction gear used to put the structure into motion. […]

Finest layout of yesteryear

[…]