[…]

Subscription: Subscription - Digital

Trains, March 2021

[…]

Welcome to the new home of Classic Trains!

Welcome to Trains.com, the new home for Classic Trains Magazine online and for all the content we publish on BIG trains from the 1920s through the 1970s. In this video, Trains.com Executive Producer David Popp talks about how to log-in to the new Trains.com website so you can get the most out of a Classic […]

Model Railroader, April 2021

[…]

MR Product Review Video Piko G scale 0-6-0

Having trouble viewing this video? Please visit our Video FAQ page Piko’s G scale 0-6-0 now comes with sound. In this video, MR’s Dana Kawala test-runs the model in the workshop so you can see it and hear it in action. […]

Piko G scale 0-6-0

Piko’s G scale 0-6-0 now comes with sound. In this video, MR’s Dana Kawala test-runs the model in the workshop so you can see it and hear it in action. […]

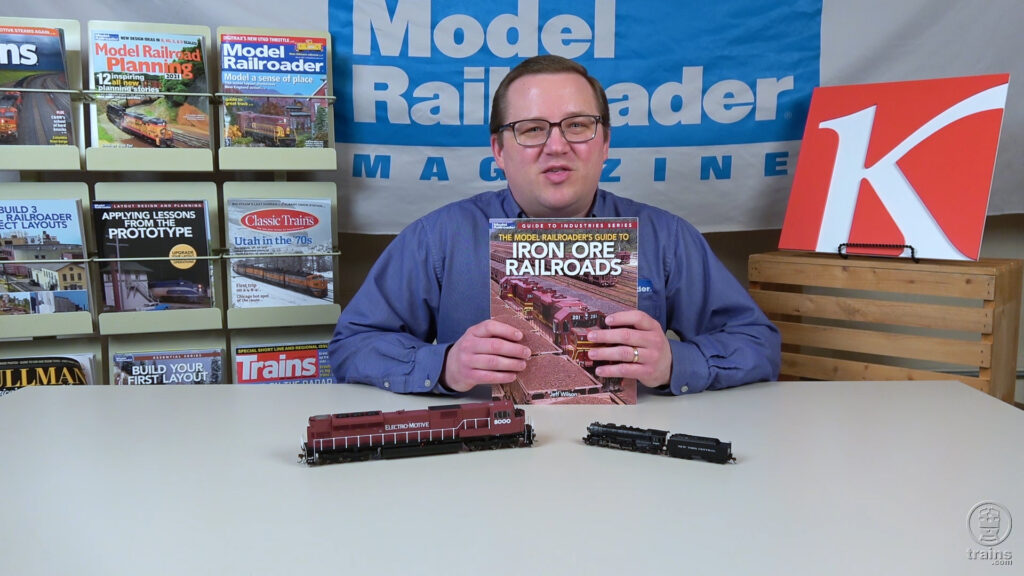

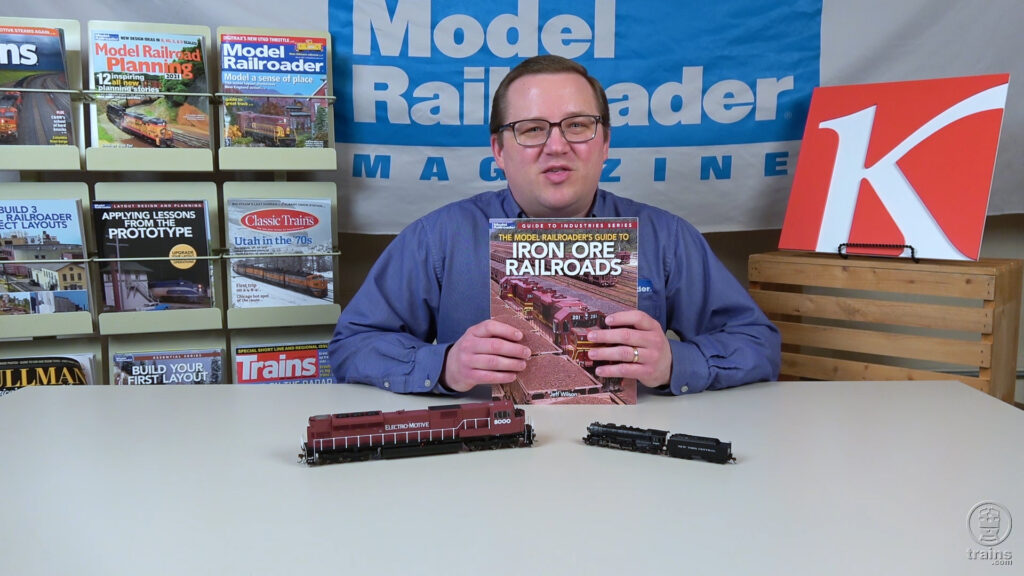

Operating the N scale Bachmann 4-6-4 Hudson with sound; SD80MAC; iron ore book review

In this installment, Cody test-runs Bachmann’s new sound-equipped N scale New York Central 4-6-4 Hudson, as well as Athearn’s Genesis 2.0 HO scale SD80MAC. He also looks at Jeff Wilson’s latest book, The Model Railroader’s Guide to Iron Ore Railroads. In addition, Cody shares tips about using Rails Unlimited reproduction railroad industry directories to improve […]

Operating the N scale Bachmann 4-6-4 Hudson with sound; SD80MAC; iron ore book review

In this installment, Cody test-runs Bachmann’s new sound-equipped N scale New York Central 4-6-4 Hudson, as well as Athearn’s Genesis 2.0 HO scale SD80MAC. He also looks at Jeff Wilson’s latest book, The Model Railroader’s Guide to Iron Ore Railroads. In addition, Cody shares tips about using Rails Unlimited reproduction railroad industry directories to improve […]

On calling stations . . . and cows!

Sixty-odd years ago, I was a youth living in Palmyra, Wis., where my father, Ben Eller Sr., was the station agent for the Milwaukee Road. Palmyra, 42 miles west of Milwaukee, was on the Madison Division, the original line to the state capital via Milton and Janesville. When I was 12, I got braces on […]

The Odyssey of UP 2488 on the Jericho & Mt. Zion Railway

Name: Ray Wheeler Railroad Name: Jericho & Mt Zion Railway Location: Lynnwood, WA Scale: G scale Theme: Tourist railroad with freight operations in the modern era. Description: The Odyssey of UP 2488 on the Jericho & Mt Zion Railway. AristoCraft 2-8-2 live-steam Mikado makes the run with a local freight. […]

Model Railroader, March 2021

[…]

Classic Toy Trains, March 2021

[…]