Built by Others is an article series showcasing layouts constructed by modelers using plans and projects from the pages of Model Railroader and its associated magazines. The Olympia project was an On30 layout built by the MR Video Plus team for a series of videos that can be found on Trains.com Video. A “what if” story by designer David Popp ran in Model Railroading: The Ultimate Guide 2020 covering two possible expansion ideas. – Ed.

Built by Others: Michael Maurer’s On30 Wood Hog Lumber Co.:

By Michael Maurer – photos by the author

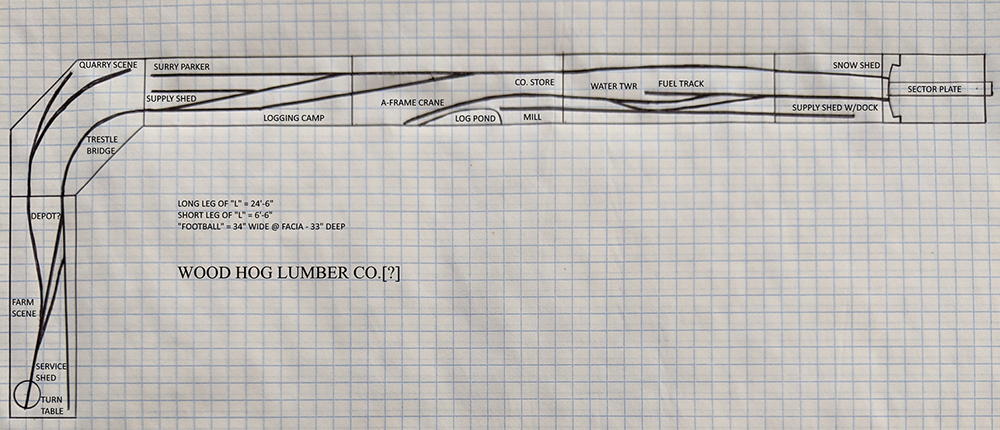

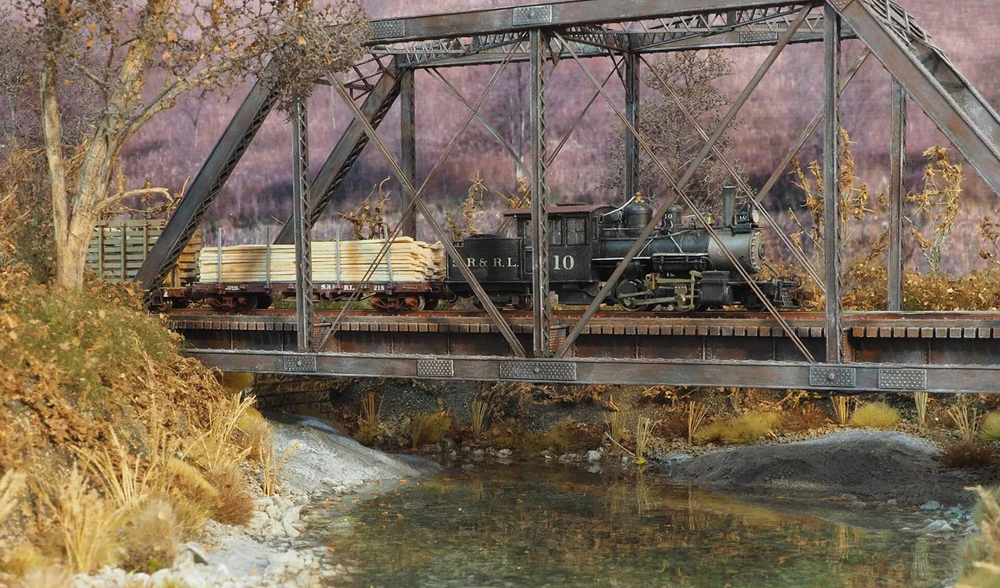

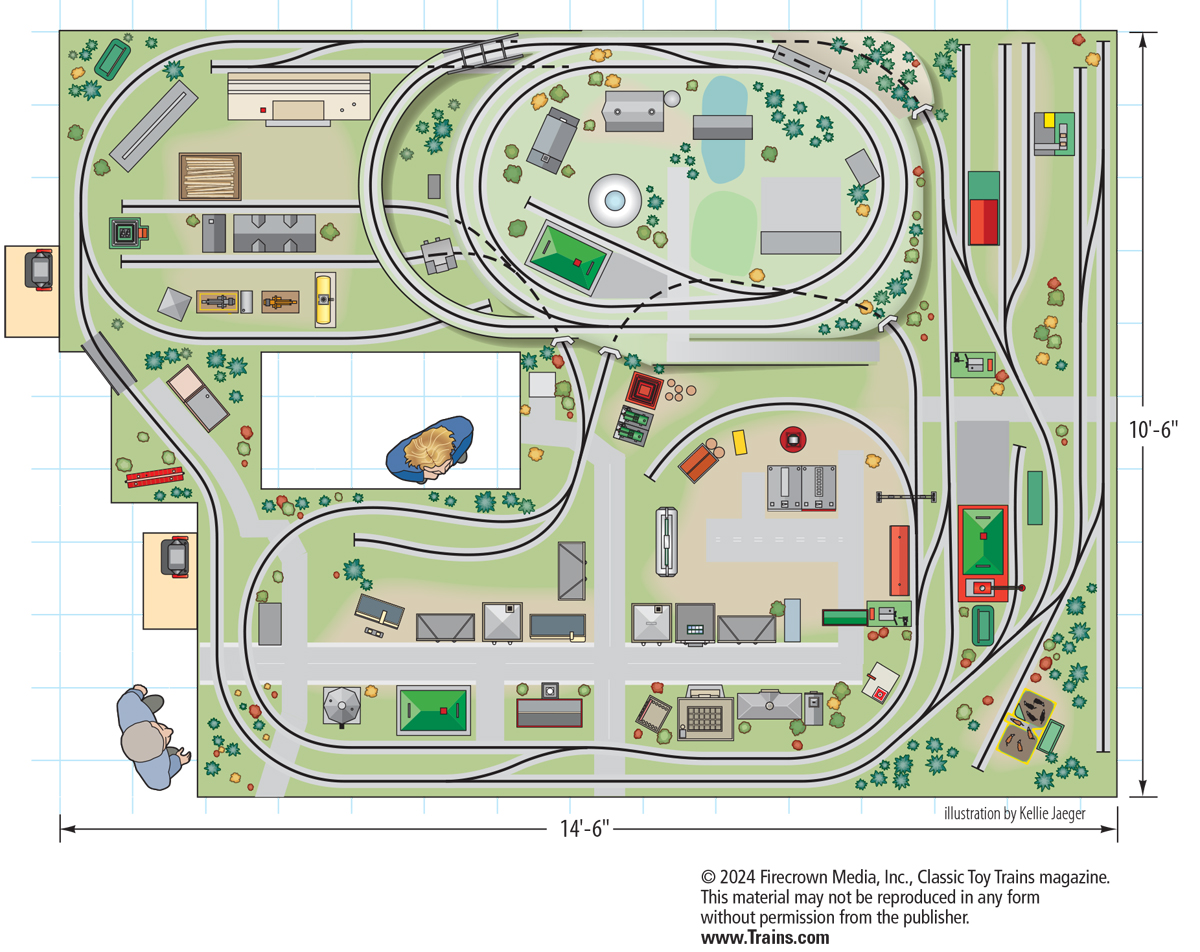

I’ve had an interest in logging railroading for some time. Recently, I started building my own version of the Olympia & Sand Creek On30 layout. I’d followed some of the videos on MR Video Plus (now Trains.com Video), and I found the complete track plan as designed by David Popp in Model Railroading: The Ultimate Guide 2020. Because I had the space, I stretched the original plan several feet, making for a longer railroad that still follows the same track arrangement.

I named my logging operation The Wood Hog Lumber Co. I named it in honor of my dad, who’s CB handle back in the day was “Wood Hog.” Dad was custom cabinet maker, and he taught me everything I know about woodworking, so I get my skillset for building benchwork honestly. When working on the layout, it brings back great memories of being with him in his shop. It’s a great feeling to know that a little bit of my dad is in the work I do today.

In the early 2000s, I’d gotten interested in On30 thanks to a couple of guys I’d met at the Winston-Salem Southbound Model Railroad Club in Winston-Salem, N.C. Club members Charlie Flichman and Rob Morrison were both On30 modelers. I loved what they were doing, but at the time I was heavily into HO, since that was the club’s modeling scale. Both Charlie and Rob were excellent modelers and were instrumental in me getting involved in the National Model Railroad Association. I still remember Charlie’s layout in his basement and the scratch-built cars Rob built. They were truly talented guys.

I started my Wood Hog Lumber layout in 2020 because I’d became unemployed due to COVID. While I looked for work, I also spent time working on the layout. I’d been inspired watching videos about the Olympia logging railroad project on Model Railroader Video Plus, so it seemed like a good starting point. To fund my foray into On30, I liquidated several thousand dollars of HO equipment.

Picking the Olympia plan and adapting it for my own space was easy. I loved the layout’s out-and-back element because that’s how the real railroad runs. And the L-shaped along-the-walls layout fit my space. Actually, I had a bit more room than the plan required, so with permission, I stretched it to fill the room. (After all, if your spouse gives it to you, you probably should take it, right?)

I also really wanted to get into operating and planning out how the logging railroad would work. While that’s still a bit out into the future, I’m very interested in developing and solving the puzzle how the railroad will run.

Same layout, new space – Michael Maurer’s On30 Wood Hog Lumber Co.

From the photos and track plan you can see that the layout is in an L shape. However, since I started it, we’ve moved. As a result, I must reconfigure the benchwork to fit our current home, as it will be installed in a bonus room above our garage. The railroad will need to be converted from an L shape to a U so it can follow the walls around the new space. Also, the new space isn’t long enough for the layout as is, so I will need to rearrange the pieces and make new corner sections. At this point, the railroad is in storage awaiting modifications.

Following the original plan, I had built a shadow box structure along the entire layout. The bonus room that will house the railroad is typical for rooms above the garage and has 5-foot knee walls that then angle up to the ceiling. The shadow box as built is too tall. I will have to either modified it to fit, or I may need to remove it completely and attach the valance to the ceiling instead, making it independent of the layout itself.

Construction tips from the videos

In watching the Olympia & Sand Creek video series on Trains.com, I picked up a number of layout building tips that I included on my Wood Hog Lumber layout.

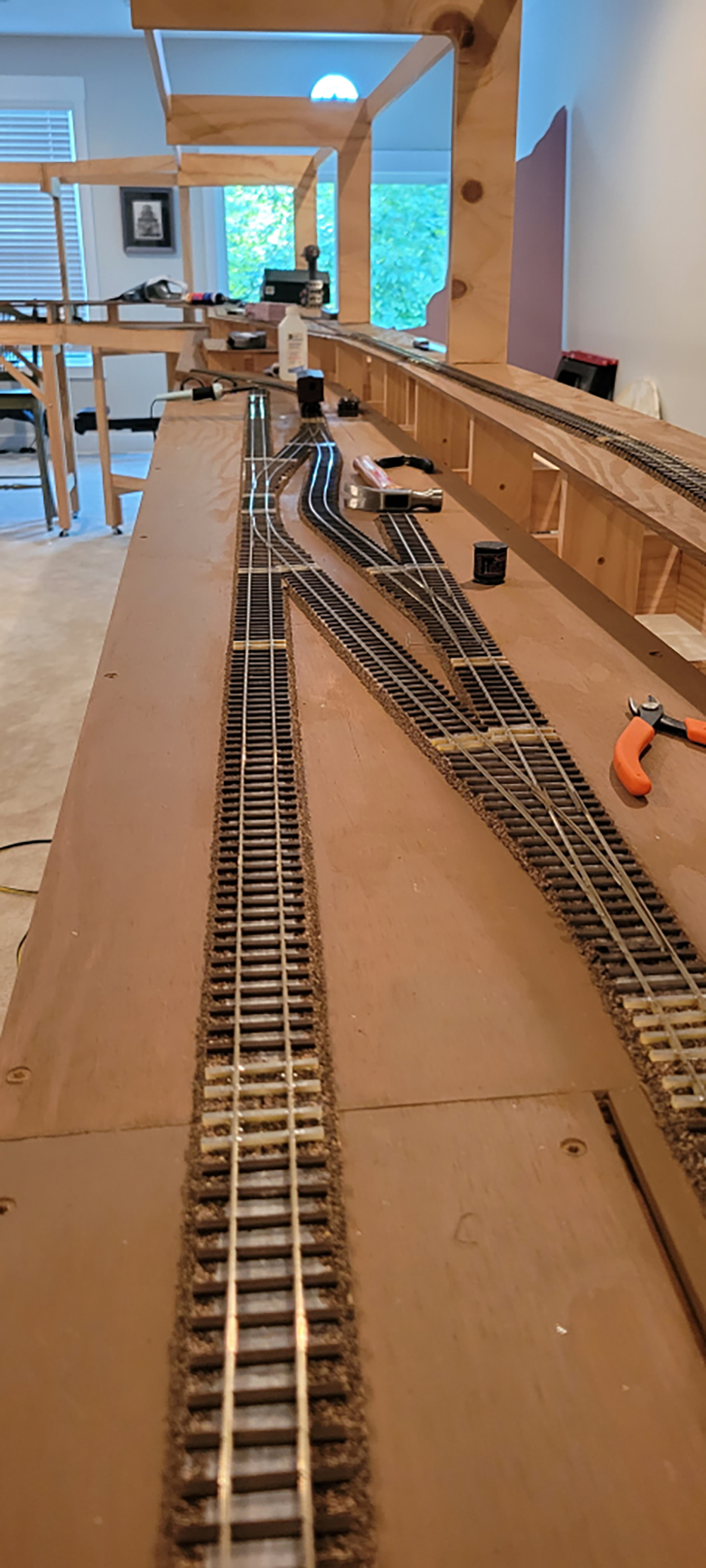

Although I made my version of the layout longer, I still used the original plans for the benchwork as shown in the video series. I used clear pine for the legs and frame, and MDF for the sector plate. The clear lumber is more expensive, but the clean, solid layout it produces makes it well worth the investment.

One thing I really liked from the video series was the use of pattern maker’s dowels to align the layout sections. These are made from steel or brass and lock the layout sections together perfectly each time they are joined. In the videos, David got his dowels from C&L Finescale in England, but they are no longer available there. I bought mine on eBay in 2021 and can no longer find them listed either. However, if you Google “pattern maker’s dowels,” you will see there are some other options and sources. They work really well for holding the layout sections in alignment, which in turn keeps the track between the sections lined up too.

I used Midwest Models HO scale cork for the roadbed. Most of the beveled profile will be hidden by the scenery material once it’s on the layout, but I like how the cork helps deaden the “woody” sound when trains run on the layout. The cork also helped me visualize the track plan as I laid it out.

Another thing I liked about the original Olympia layout was its turnout control. In the video series, they used the Blue Point system. I really like this kind of manual control as it makes me feel like I’m “doing something” as I operate the railroad. I’ll install Blue Point switch machines to all of my turnouts as I continue to build the railroad.

I plan to add some of the other features to the layout found on the original. Although I’m not yet at the scenery stage, I purchased some rubber rock castings from Cripplebush Valley Models. I also plan to build a snow shed to hide the layout’s connection to the sector plate at one end. And I’m a big fan of Kitwood Hill Models (kitwoodhillmodels.com), so I bought the same turntable David used on the Sand Creek section of his layout.

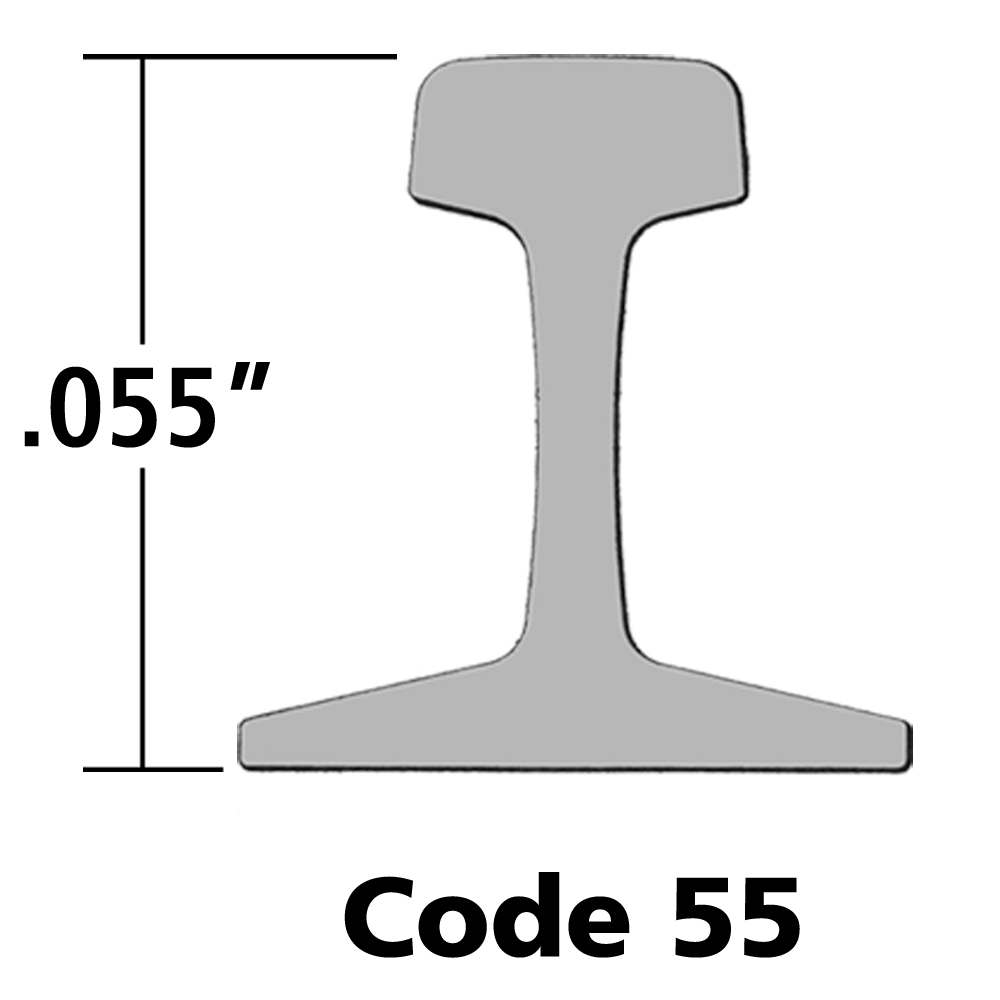

Track and the gaps between

Unlike Olympia, I chose different track based on past experiences. I opted to use Micro Engineering On30 code 83 track and turnouts for my layout. I’d used Micro Engineering’s HO scale track and turnouts before, so I was familiar with how to work with them. I also like the profile of the ME ties much better than other On30 track on the market.

Where sections of track join, instead of using rail joiners, I used Gap Masters from the American Tie and Timber Co. These are short sections of ties made from PC board material. To join two sections of track, you solder the rails to the Gap Masters ties. They come with the gaps already cut in the cladding to prevent short circuits. American Tie and Timber sells Gap Masters to match the profile of assorted brands of track in Z, N, HO, On30, and other scales and gauges.

I used these on a couple Gap Masters ties on a previous HO scale layout. They work really well where the track has to split between layout sections. The ties hold the rail firmly and keep the track sections properly aligned. Once you paint the track and add ballast, you don’t even know the PC board ties are there.

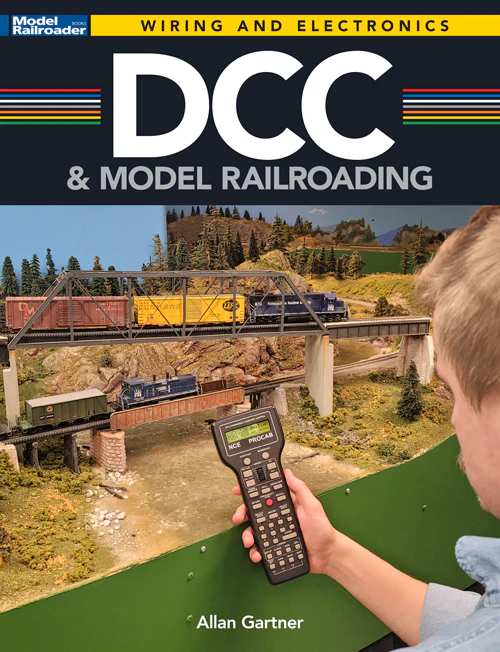

For train control, I’m using the ESU CabControl system. It seems kind of the opposite of what you would expect for operating an old-fashioned logging railroad, but I like the system’s Android based throttles. I especially like being able to swipe from one loco the next when operating. I’ve also installed ESU sound decoders in my locomotives, so the two components work together seamlessly.

More to come

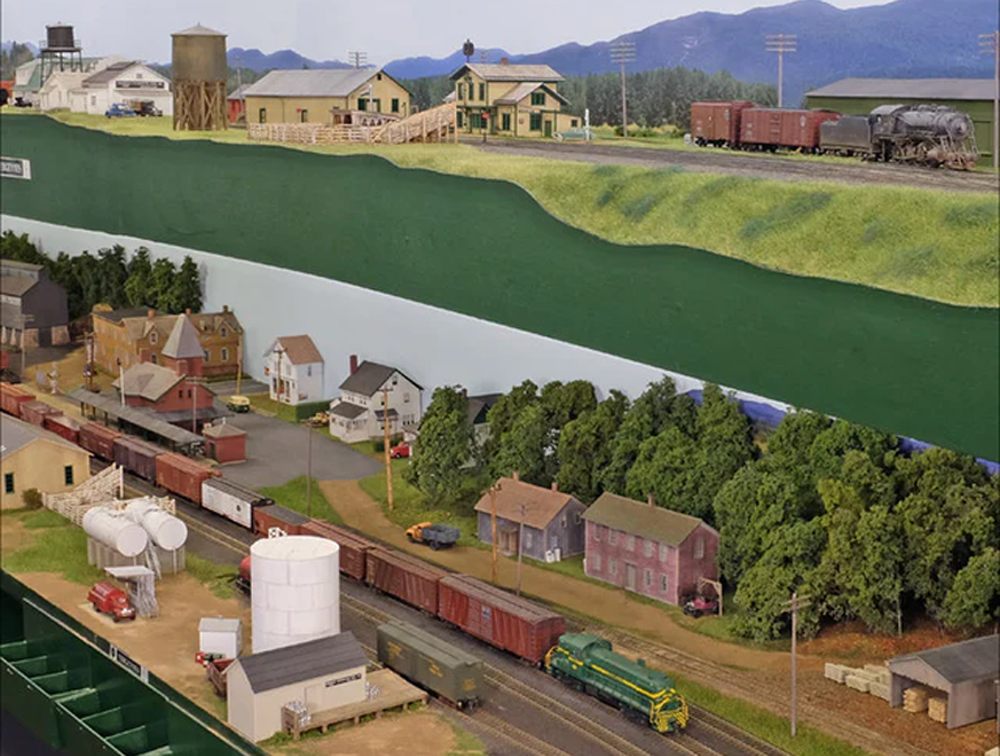

The thing I look forward to most, after getting the layout out of storage and configuring it for the new location, is the scenery. I love painting and ballasting the track. I don’t know why other than that I see it as the start of all the other important elements, such as rock work and trees. I know I have a lot to build yet, but scenery is where it’s at for me.

For my backdrop, I plan on using Trackside Scenery’s photo backdrops. While I could paint my own, I think photo backdrops step a layout’s look up a couple of notches. Because of that, I’m going to use them on my railroad.

I’ve really enjoyed following the progress on the Olympia & Sand Creek project on Trains.com Video. I always check to see if the next episode is up. Building my own interpretation of it has been a fun and satisfying experience. I am thankful for the opportunity to share a little bit of what I have done so far, and I hope that I will one day be able to show more progress of the Wood Hog Lumber Co. on Trains.com.

Michael Maurer is the great grandson of a New York Central engineer and has had a life-long affinity for model trains. Michael is an IT analyst. He and his wife Amy live in Kernersville, N.C. and are both members of the North Carolina Transportation Museum in Spencer, NC.

Made some good progress on one of the corner add-ins this week. Have the lower and high line tracks laid and wired up. Just tested out the work with running Climax #27 on the high line. Success! #wootwoot Check it out on my FB page:

facebook.com/woodhogOn30

I have done a little bit of work over the last few month before taking a break to work on other construction projects at the house. Here’s a few photos of what the WHLCRR looks like now that it’s in the new location in the U-shaped configuration.

Hope to get moving on some trackwork in the corner sections after the new year.

Enjoy,

Michael

‘Wood Hog’

https://photos.app.goo.gl/4ozHVBEuTjyaXL8E9

I love the concept and benchwork. I’ve though about using plywood “C’s” as a means of doing the shadow box. How well have they worked on for supporting the back and top?

Great to see what you’ve done.

jim

The plywood C’s are made of 3/4″ plywood so they are plenty strong enough to support the back and overhead structures. Plus, being sort of sandwiched together at each end helps too. Unfortunately, the C’s are going to have to be removed and modified to fit my new space. Thanks for your comments.

Here’s a video of my Heisler with it’s new ESU decoder and keep alive pack:

https://www.youtube.com/watch?v=OmKgKP884FU