So long as your rails are clean and your rolling stock is fine-tuned, it’s time to inspect your right-of-way for problems. This is the second of five quick articles on how to check for and fix common mechanical and electrical track problems with model railroad track.

Problems with turnouts

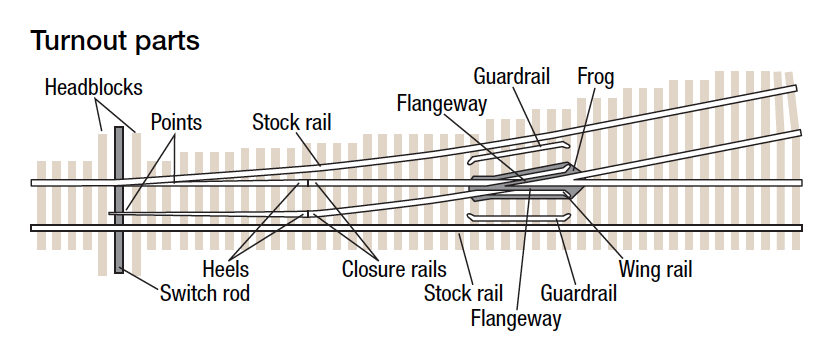

Turnouts have many places where a car or locomotive can derail. The top illustration on the right shows the main components of a model railroad turnout.

If your test train regularly derails on a turnout, you can slowly run a loose truck through each route. But since trucks that are installed on a car behave differently than a loose truck, I suggest using a Micro-Mark HO scale inspection car, which features two trucks mounted on a clear piece of plastic.

I use my National Model Railroad Association standards gauge to check that all the components of every turnout are correctly spaced. These dimensions are listed in NMRA standards 3.1 to 3.3 found online.

In addition to making sure that the track gauge is correct through each route, I verify each flangeway’s width and the check gauge (spacing between each guardrail and the frog).

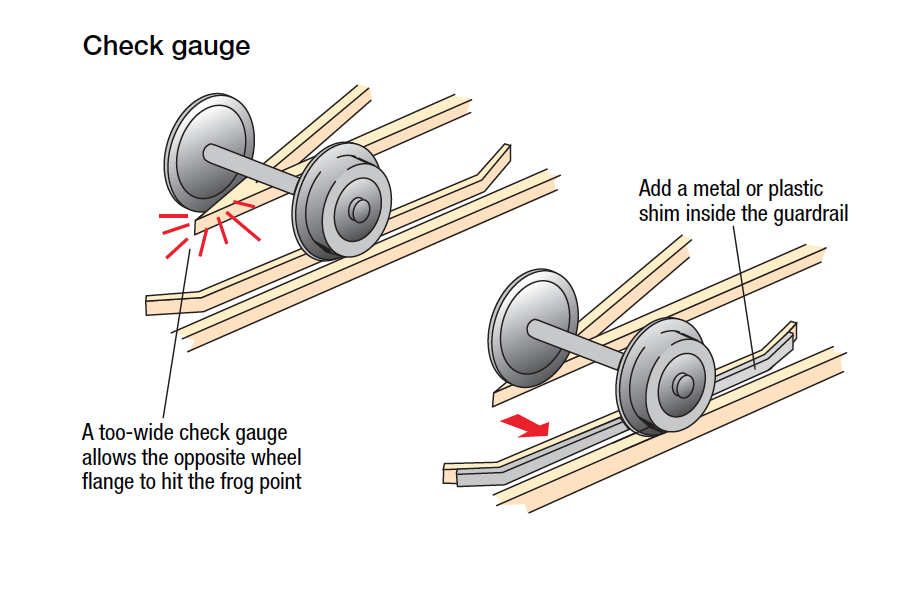

The inside edge of the guardrail should engage the back of the outer wheel’s flange to guide the wheelset away from the frog point and through the correct route. A check gauge that’s too wide or too narrow can cause rolling stock to derail.

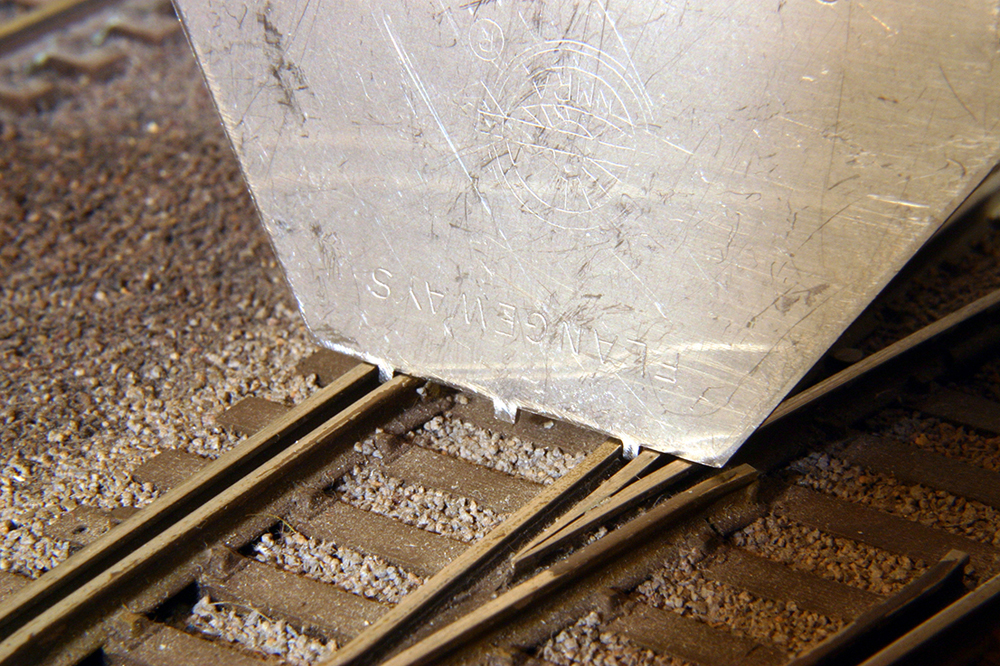

If the check gauge is too narrow, I move the guardrail toward the stock rail, or if the guardrail can’t be moved, I add a .010-inch or .020-inch styrene or metal shim, as shown in the illustration on the right. If the check gauge is too wide, I move the guardrail toward the frog, or if that’s not possible, I file the inside of the guardrail.

If the check gauge is correct, yet cars still derail, the problem could be with the frog. On some turnouts the frog is too high, causing a noticeable bump that doesn’t look very realistic and may derail cars. On a turnout with an insulated frog, a bump can interrupt current pickup, causing locomotive headlights to flicker or sounds to cut out. The frog should be filed down to the same height as the other rails. I also use a file to sharpen the frog point, if it’s blunt, so that wheel flanges will clear it.

Blunt switch points provide another place for wheels to derail. Using a jeweler’s file, I bevel the inside of each point to a flat knife edge against the stock rail. This provides a smooth transition from the stock rail to the point.

very well written and accurate, will resolve most turnout issues. Another problem can be distortion, the switch rails sitting up high somehow. John

For what it is worth, a set of ‘riffler files’ will do a lot for you. I use mine a lot for a myriad of issues, be it turnouts, details, etc. They are pretty common, inexpensive, and can be purchased either on line or in home improvement, craft or hardware stores.