Proxxon

Prox-Tech, Inc.

PO Box 1909

Hickory NC 28603 US

Price: $427.50

Website: www.proxxon.com/us

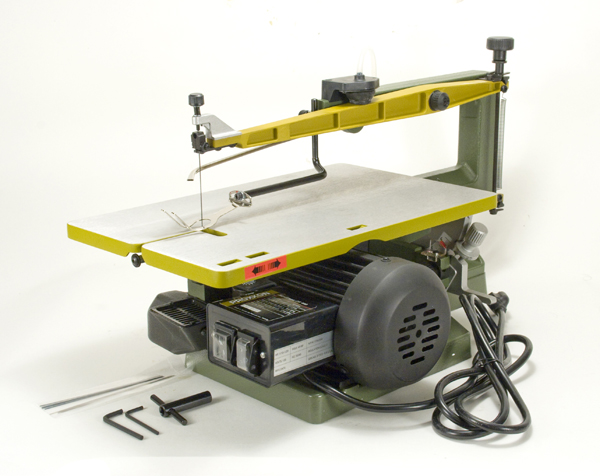

Two-speed scroll saw; cast-iron base; magnesium saw arms; 190W brushless motor; 800 or 1,700 strokes/min.; stroke length, 3/4″; throat depth, 18 1/8″; cutting depth, 2 1/2″, or 1 1/4″ with the table at a 45° angle. Overall dimensions: length, 22 7/8″; width 12 1/2″; height, 12″. Weight: 44#

Pros: Heavy, robust construction; tiltable table; well designed and manufactured; air nozzle for clearing dust; excellent performance

Cons: Variable speed would be good for metal cutting; table surface a little rough, hampering the turning of some work

The scroll saw reviewed here is one of Proxxon’s few full-size tools. The company is known for its high-quality miniature tools for model builders. A scroll saw is difficult to scale down.

Quality-wise, this saw is typical of the company’s other products, many of which have been reviewed in these pages. It comes with a comprehensive, well-written owner’s manual in three languages (English, French, and Spanish), which covers all of the saw’s parts as well as providing instructions for getting going on it.

The saw has a cast-iron base, giving it substantial weight and stability. At 44 pounds, it is heavy enough to be used as a temporary or portable tool, if you wish, just placed on top of your workbench, or it can be permanently attached to your bench via the mounting holes toward the rear of the base.

The table is an aluminum casting. It can be set to five predetermined, indexed angles (0°, 10°, 20°, 30°, and 45°), or to any angle in between, up to 45°. There is also a fine-adjustment knob, making it easy to fine-tune the angle if, say, you’re using a square or angle gauge to set the table.

The moving arms of the saw are made of lightweight magnesium castings. They are pivoted toward their rear ends and are tied together by a vertical arm at the rear, giving them simultaneous parallelogram motion.

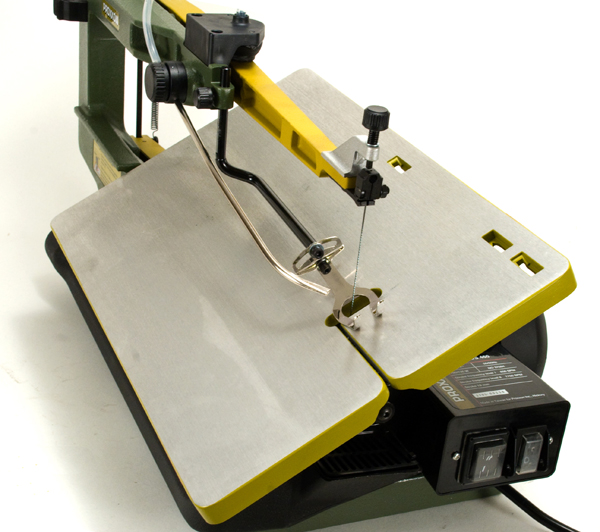

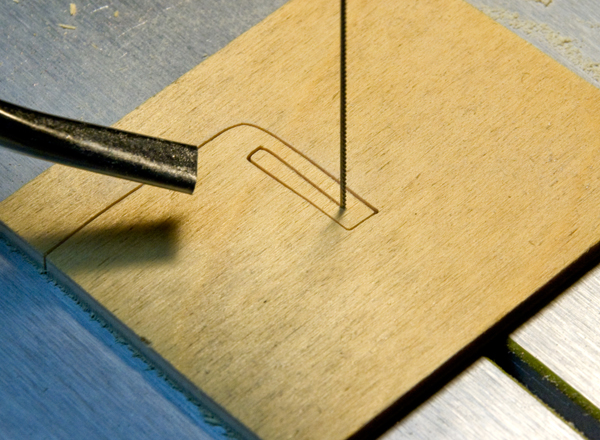

Five coarse and five fine blades are included with the saw to get you started. These are a standard 5″ long—you can get replacements, and also different blades, at any woodworking-supply shop or hardware store. Jeweler’s-saw blades can also be used for ultra-fine work. Blades are held between two removable clamps. There are depressions near the edge of the saw’s table to hold the clamps while installing the blades. This makes the job easy, as the clamps must be a set distance apart. A special wrench is provided for tightening the blade clamps, and which clips in place at the rear of the machine when not in use. The clamps/blade assembly is then placed in the saw, and the blade is tightened using a screw knob at the rear of the upper arm. A basic blade chart is provided, suggesting the number of teeth per inch for different materials, as well as which of the two motor speeds are best for which materials.

Once the blade is in place and tightened, a square can be used in conjunction with the fine-tuning knob to ensure that the blade is absolutely perpendicular to the table. An adjustable hold-down aids in keeping the work flat on the table. All scroll saws tend to lift the work on the upstroke, so you must be mindful of that and always hold the work firmly to the table. The hold-down helps.

Another nice feature is the air hose that connects to the top arm of the saw. As the saw works, a small bellows is activated, providing a stream of air that can be directed toward the work via the adjustable nozzle. This helps to keep the cutting area free of sawdust as you work. A plenum is built into the saw beneath the table, with an intake below the blade. At the rear of the saw is an outlet to which may be attached a shop vac or other vacuum system for sawdust control—nice.

The saw is powered by a two speed, 190-watt motor, giving speeds of 800 or 1,700 strokes per minute. This is adequate for most work, though sometimes an even slower speed is handy for some metals. A variable speed control would be nice.

The saw is fairly quiet in operation, though louder at the higher speed. At 1,700 strokes, there is some vibration. However, even with the saw just set on the workbench, it was stable and did not want to walk around. At the lower speed, the vibration was much less. With a coarse blade and the higher speed, you can really move through the work. For more control and precision work, the slower speed and a finer blade are better choices.

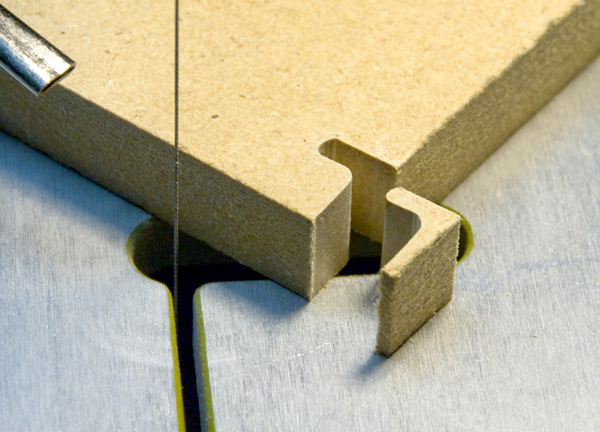

I tried the machine on 1/8″ birch plywood, 1/16″ copper sheet, 1/8″ styrene, 1/4″ birch plywood, and 1/2″ MDF. It performed beautifully on all materials. Of course, the thicker or denser the material, the slower the cutting speed. The coarse blade tended to pull a little more on the up-stroke. I found the table-surface finish to be a little rough, making it more difficult to move and turn small work pieces, which wanted to stick a little to the table. The table could be sanded smoother or an overlay of some smoother material could be made. Also, the hold-down was okay for larger work but was in the way for the smaller stuff. I removed it and things were fine.

This is a fine, well designed and crafted machine. If you’re in the market for a saw with this type of capability, Proxxon’s is definitely one to consider.