Scratchbuild a coal company: Before oil and electric became practical, coal was the fuel of choice for heating homes and businesses. Almost every city and town had one or more businesses that supplied coal. They received clean coal in large bulk, in various sizes, usually by railroad, and sold it in bags, buckets, and truck loads.

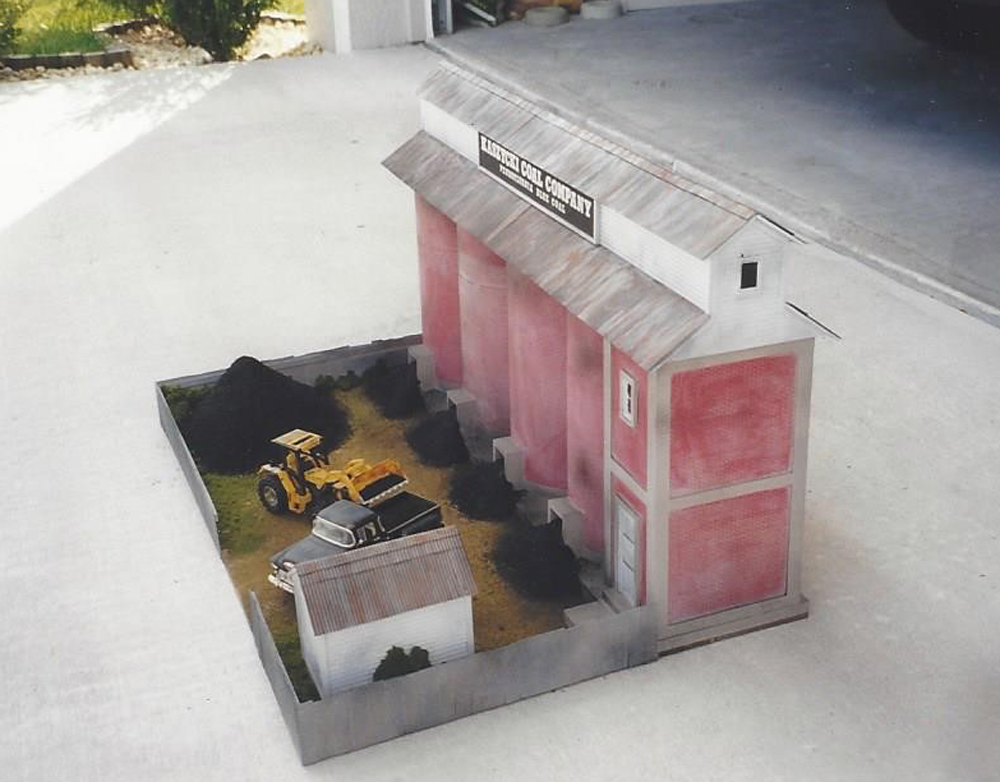

Coal company buildings were usually simple, consisting of wood or masonry bins, a mechanism to fill them, an end building for housing a scale to weigh the materials, and a small office. I decided to build a structure for an indoor display. My business was 2 ½’ wide, 2’ deep and about 18” high.

Materials list

- 1/8” plastic or hardboard

- ½” plastic or hardboard

- 6” diameter plastic pipe

- .040” styrene

- .080” styrene

- Concrete colored water-based paint

- Adhesive, such as E6000

- Ballpoint pen

- Plastic patterned sheets from Plastruct

- Brick, G-scale red clay (PS-90)

- 3/8” clapboard siding (PS-57)

- Corrugated siding (PS-27)

Starting the coal company build

For the base, I cut a piece of ½” expanded PVC sheet. The three bins were made from pieces of 6”-diameter plastic pipe. I made the roof, lift tower, and the office from 1/8” expanded PVC sheet.

The lift tower is a simple box built out of 1/8” expanded PVC sheet. The roof and roof extension piece are also made from 1/8” expanded PVC sheet, built to fit the flat tops of the bins and lift tower. I staged a mock-up to check the fit and visual presentation. I felt the lift tower looks better on the end instead of in the middle of the structure.

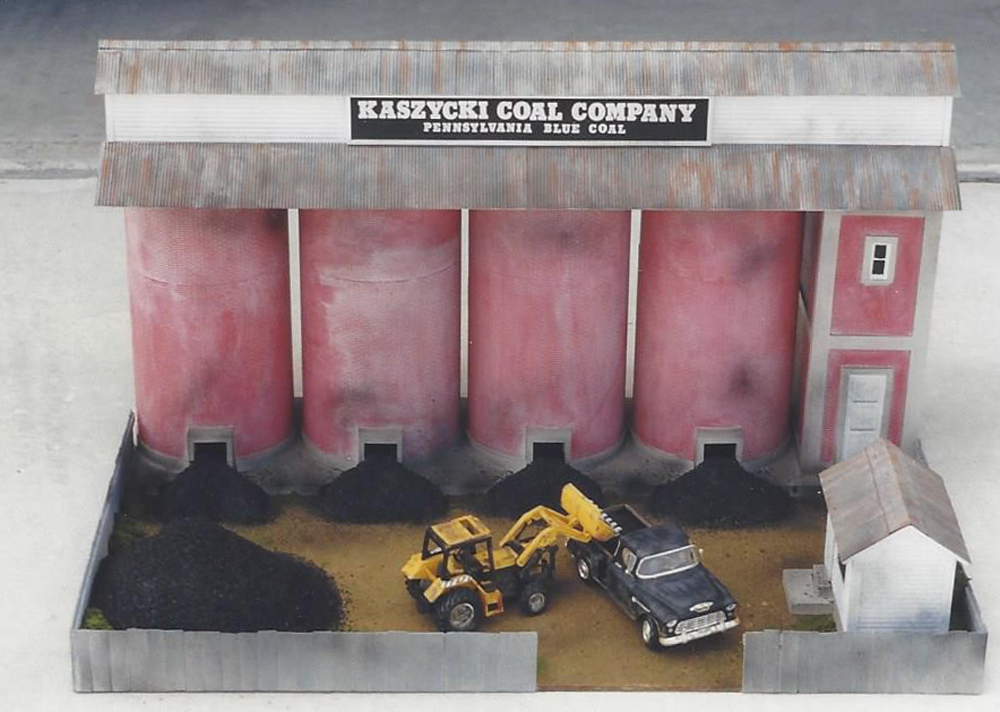

I decided that my bins would resemble masonry with concrete discharge chutes at the base. I ordered sheets of brick patterned plastic sheets (see materials list) and glued them around the pieces of the plastic pipe. I suggest that you paint/weather the bins before you mount them to the base.

Paint and weather the structure pieces

I weathered the brick pattern by painting it with a coat of water-base concrete color paint, then wiped most of it off before it dried with a cloth. The front of the brick will show through, leaving paint in the mortar joints, highlighting them.

The more paint that you wipe off, the more of the red brick color will show through and the newer the wall will look. Leaving a thin layer of paint will remove the plastic shine and leave a nice patina. Note: Paint a small section at a time. You do not want the paint to dry before you get the results that you want.

I used .040” styrene to represent the concrete framework of the lift tower. Inside the framework, I added brick plastic sheets, and weathered the same way as I did the concrete bins.

I covered the roof and the extension roof with plastic patterned corrugated siding. I cut the material to a scale ½” foot width for the overhang. This material comes in a gray metallic color, which I toned down by drybrushing areas of light gray, roof brown, and rust. The sides of the roof extension and the gable ends are covered with 3/8” clapboard siding. The material is white, but I painted it to dull the plastic shine and drybrushed on a little coal dust here and there.

The signs are a strip of .080” styrene with 1/16” x 1/16” styrene strip for the border. Since my structure is kept indoors, I painted the background flat black and used peel and stick letters.

The office is made of 1/8” expanded PVC sheet covered with the corrugated and clapboard siding, painted and weathered like the main building. I made the doors and windows from bits of strip styrene.

The fence is made from .080” styrene. I used a black ballpoint pen to scribe vertical lines to represent boards and staggered the boards on top in random places. An 1/8” x 1/8” strip about 3/ 8” below the top adds just a touch of detail. I drybrushed the fence medium gray with lots of dirt here and there.

Final coal company details

The coal piles are crushed coal pieces. It would be reasonable to have some weeds end bushes growing around the edges and corners. The parking lot could be paved with asphalt. Better still, the lot could be dirt with ruts and puddle or two, and lots of spilled coal. Add some vehicles to complete the scene.

Since the back of the structure is up against a steep embankment, it’s plain with minimal detail. All that is really needed is a spur track coming into a simulated concrete receiving pit at the base of the lift tower. An alternative is to elevate the track with a fill or wood trestle high enough to justify a chute for gravity delivery into the lift.

The company in my hometown that gave me the idea for this piece was built against a very steep embankment that was high enough to build a wood delivery chute. It was flat on top and wide enough for a single track and a two-lane street. This building is an ideal excuse another operational move and a couple of extra hopper cars.

Like this article? Check out more projects here.