FORT WORTH, Texas — On a sunny Thursday afternoon, officials from Canadian National Railway and Wabtec gathered outside Wabtec’s Fort Worth locomotive factory to celebrate the delivery of a brand new locomotive for Canadian National Railway.

Or so it appeared.

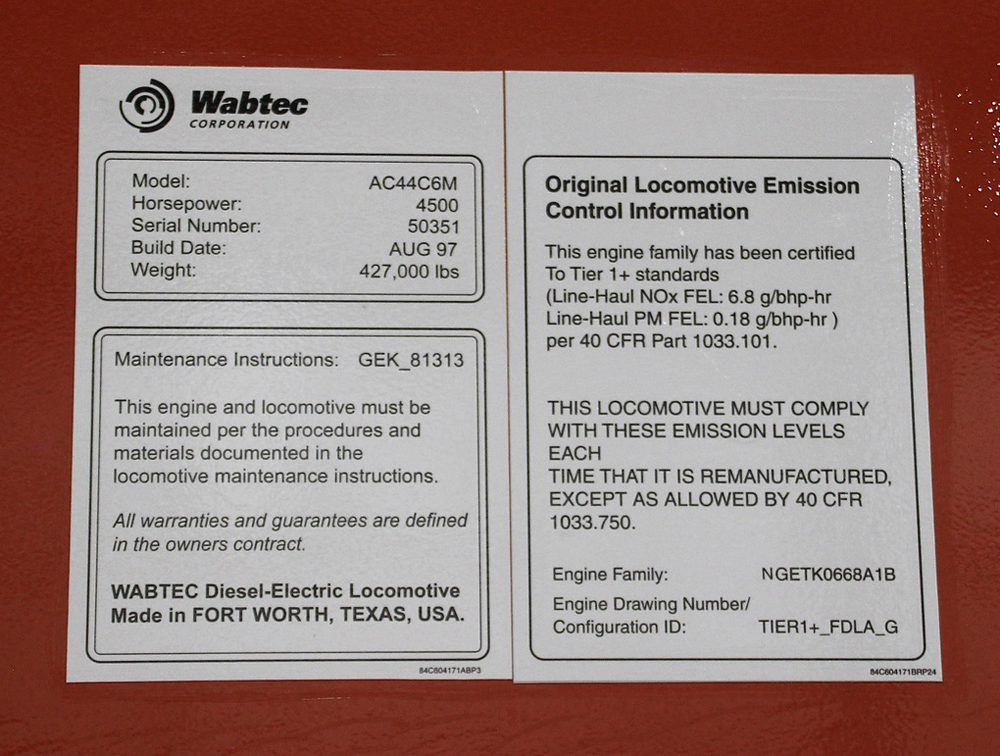

In fact, the officials were posing for photos with AC44C6M No. 3300, the first of an order of 50 of the remanufactured 4,500-hp locomotives. While as shiny and spotless as any unit built new at the Fort Worth plant, is actually a mix of new, rebuilt, and upgraded technology. It promises more pulling power, better fuel efficiency, and reduced emissions, all at a lower cost than a new locomotive.

“This is a huge event for us,” said Rob Reilly, CN’s executive vice president and chief operating officer. “A big part of our future is being able to grow with our customers, so to be able to have these new or rebuilt locomotives is going to allow us to be able to handle that. … These are more reliable, they allow us to have greater tractive effort, and then they also are [significant] along the lines of sustainability, with our science-based target initiatives, our net-zero [carbon emissions goal] for 2050. So it ties into everything that we’re doing, and we’re very excited about it.”

The remanufactured units’ mix of the new and proven makes them both a comfortable addition to the CN fleet — “It fits right in with our locomotives, with everything else we do,” says Rance Randle, CN’s senior vice president, mechanical and engineering; “We know how it interacts, how it functions on our network” — and a technological step forward.

“When we bring on new equipment and improve our technology base, it’s always exciting,” says Mark Grubbs, CN’s vice president, mechanical. “Not just for our customers to receive better service, but mechanically, it challenges us to improve our skillset and enhance our aptitude, which pushes us along with technology.”

Wabtec officials were just as effusive as CN’s.

“I always love to see a customer embrace a new technology for the first time,” says Gina Trombley, Wabtec’s executive vice president of sales and marketing and chief commercial officer-Americas. “And it’s been a great day with the CN executive leadership team, walking around, seeing what really happens when you modernize a locomotive, which is a pretty complicated and really cool process.”

The degree to which the locomotive appears indistinguishable from a new product is “the special sauce” of the remanufacturing process,” Trombley says. “We have managed to find the perfect combination of bringing in the best of the new technology and keeping what was solid and good as it was, and then dragging down how much fuel it’s burning and how much carbon it’s emitting. It’s kind of the best of all three things, which is perfect.”

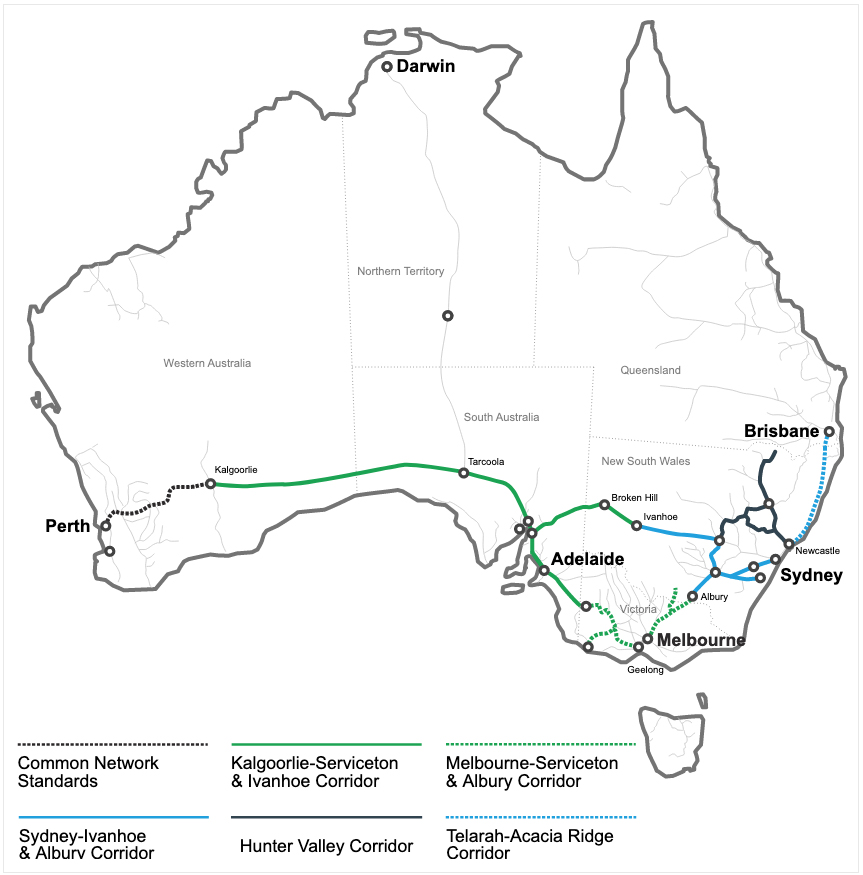

The remanufacturing business has become huge for Wabtec at a time when few railroads are ordering new locomotives. In addition to the CN locomotives in various stages of completion — including two that headed off for a test run as the officials were posing for photos — the factory floor also included units for Union Pacific and Norfolk Southern, as well as a few for Australian mining company Fortescue Metals Group.

“The North American fleet’s older than it’s ever been,” Trombley said, “ and even though there’s not new, there’s still a need to keep investing in the fleet, to make it more reliable, to make it do more work … You take out DC technology, put in AC, and all of a sudden, the unit’s doing 55% more work than when it came in the door.

“Even though we’re not building a lot of new locomotives right now, I’m super proud of what Wabtec is doing to innovate the fleet that is out there. So we love it. And who doesn’t love a locomotive?”

Besides being cheaper to rebuild, they are more reliable and cost less to operate than Tier 4 locomotives. Doesn’t matter if it’s Wabtec or Progress locomotives. Told to me by various individuals that both haven’t lived up to expectations. Still working the bugs out. Also they aren’t as fuel efficient, and cost more to repair because all the technology (they run great when they work but are a bitch to diagnose and fix (because they are so complex) when they don’t.

My neighbor is a Trucker. He tells me that prior to the government imposing Tier 1 levels, the industry almost doubled the mileage of the trucks. Tier 1 cut mileage if half. They got millage back. Each new Tier did the same thing. Also need to use DEF for pollution control, which is another expense on top of Diesel fuel. In the last 20 plus years truck millage hasn’t increased.

How about the goal of “Quality, Value and Service” as the true performance metrics?

Don’t kid yourself. The “allure” is significant cost savings. They’re able to save a ton of money by not having to bring these units up to Tier 4 standards. This is all hype and another way to put more money is shareholders pockets. If you think this does anything for “customers” or helps the “environment”, than I have some incredible swampland in Florida you’d certainly be interested in. All these manufacturers do the same thing: rebuild old units because it allows them to get around Tier 4 standards. It’s ironic: when ports are forcing truckers to upgrade their equipment to new, low pollution trucks, the RR’s get around this by “rebuilding” old units that the government allows them to retain Tier 1 standards.

“You take out DC technology, put in AC, and all of a sudden, the unit’s doing 55% more work than when it came in the door.”

While she no doubt is better now than she was as an aged Dash 9 when she departed for rebuilding, that percentage doesn’t sound plausible.

It’s all in how “work” is measured. DC motive power has limitations that AC does not. Such as “minimum continuous speed” restrictions on DC motors.

I can attest to the vast superiority of AC vs. DC when it comes to starting a heavy train on a grade or sustained low speed pulling power.

If we’re talking HP, then there isn’t much difference. 4500 HP in AC won’t result in much higher running speed than 4400 HP in DC.

It’s very plausible, and I’m assuming he’s comparing it to CTE(Continuous Tractive Effort). I think a Dash-9 would only be rated at 105K lbs @10MPH. Am AC unit obviously has a higher CTE. At 55% greater CTE @10MPH that = 162,750 lbs. CTE @10MPH. Keep in mind these units were also ballasted to 427K lbs.

Isn’t the rebuilding boom really to keep Tier-1 locomotives in operation instead of buying Tier-4? How can the PR departments construe this as “sustainability”. If they claim the goal is net zero, why aren’t the class 1s stringing catenary and converting to electric? Nothing but corporate greenwashing hype to maintain business as usual.

Do we have the traffic density to electrify across most of the country? No.. Also the Class 1’s would be operating two seperate forms of motive power, which would increase cost. Not efficient at all. Diesels can go anywhere and that’s the allure.

Net Zero doesn’t mean much, and nothing in life is zero.. PR talk is just that..

You don’t think the BNSF transcon or similar corridors don’t have the density?

If nothing else, the operational benefits, lower operating costs, less maintenance would justify electrification. We don’t have electrification because it requires a long term investment horizon. Class 1 executives only care about vesting their options for the next quarter or next year.

The new Amtrak Chargers are Tier 4 and having some problems as with the Michigan train recently.

These rebuilds are designated “Tier 1+” Can someone explain what Tier 1+ is compared to simply Tier 1 and is it a significant improvement in emissions?

It’s a good piece of writing but it lacks the detail of a detail-oriented periodical such as Trains. Who was this locomotive originally built for? A few extra details of what was added/subtracted would be nice.

CN’s AC44C6M’s are built from CN’s own fleet of C44-9W’s (CN 2500-2696, IC 2697-2726, CN 2727, BCOL 4641-4654). Don’t have the individual unit numbers yet.

Yes, but the BCRail units were unique. I’m guessing they went first.

Here are the first ten scheduled. Need for overhaul determines which units are rebuilt first.

New Previous

CN 3300 CN 2641

CN 3301 CN 2591

CN 3302 CN 2582

CN 3303 CN 2588

CN 3304 CN 2572

CN 3305 CN 2563

CN 3306 CN 2573

CN 3307 CN 2579

CN 3308 CN 2570

CN 3309 CN 2598

Thx

Very well. Thank you. For some reason I was under the impression the BC units were the oldest of the lot.